Metal Etching Industries

Our metal etching services have met the needs of the most demanding industries in many specialized fields. BE-CU is experienced in meeting high standards and special requirements while providing fast production, quality and cost reductions for high volume metal etching.

- Instant Quotes&DFM Feedback

- Parts as Fast as 2 days

- Tight Tolerances

- Hand Metrology,Laser&CMM Inspections

Homepage » Metal Etching »

30 Years of Adaptability To Special Requirements

In the vast realm of manufacturing and production,Metal etching applications are as diverse as they are integral. From small-scale industries to major multinational corporations, the range of precision etching technology uses is extraordinarily wide, redefining the limits of what we can produce and accomplish.

With over 40 material options and bulletproof tracking and documentation of every part through the whole facility, BE-CU is proud to partner as a supplier of top quality etched parts and components to vital industries.

ISO 13485:2016 and ISO 9001:2015 certified for delivering exceptional japanese-style precision etching services, BE-CU is certain to have the manufacturing capability to meet your requirements.

-

Aerospace Etching

From the early days of aviation to the latest advancements in spacecraft technology, etching has played a pivotal role in the design and production of various aerospace parts.

-

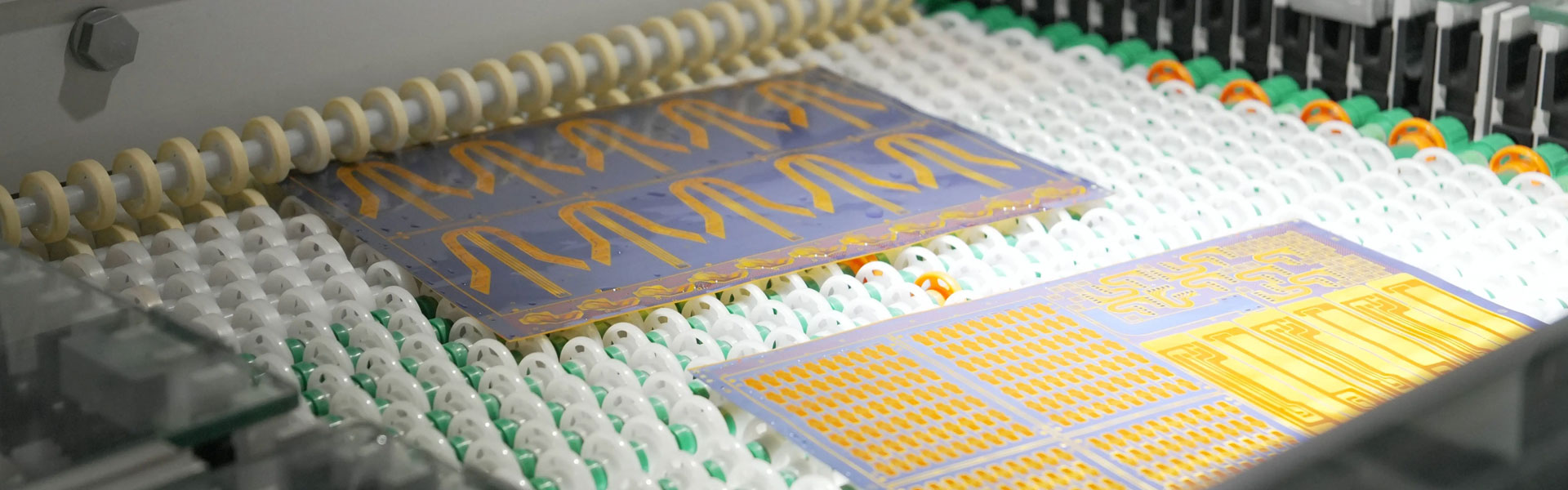

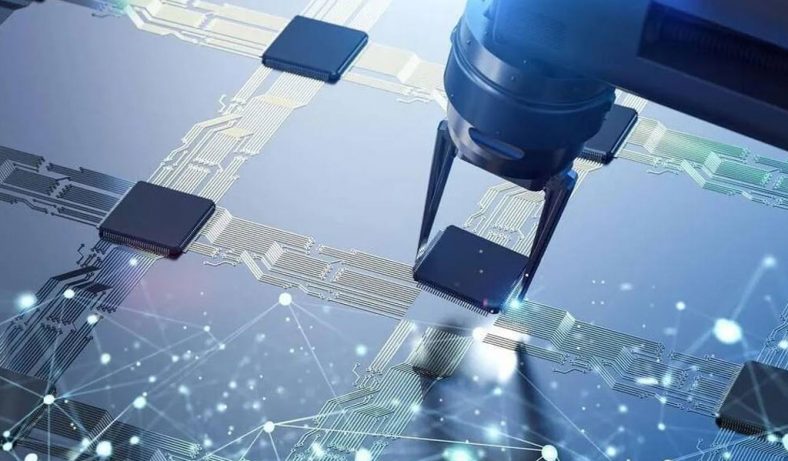

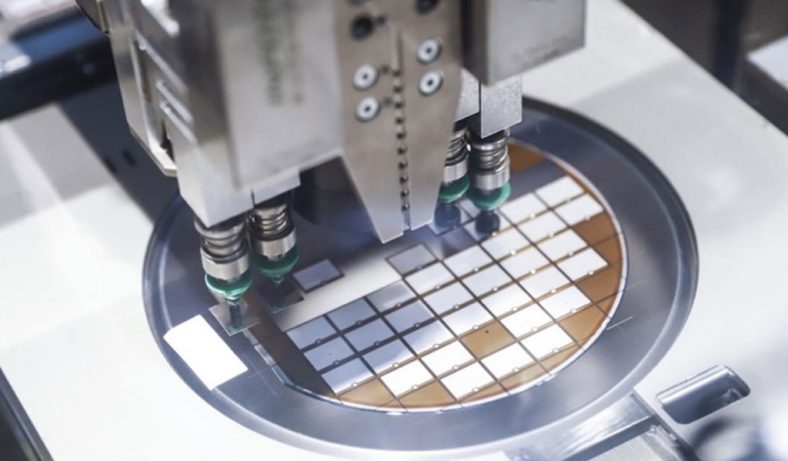

Electronic Etching

Electronic etching is a sophisticated manufacturing process used primarily in the production of electronic components, particularly in the semiconductor and microfabrication industries.

-

Medical Etching

Medical etching is a specialized process that involves the precise removal of material from medical devices, instruments, and implants to achieve desired surface characteristics and features.

-

Optics Etching

Optic etching is a specialized process used primarily in the manufacture of optical components, such as lenses, mirrors, prisms, and other devices that manipulate light.

-

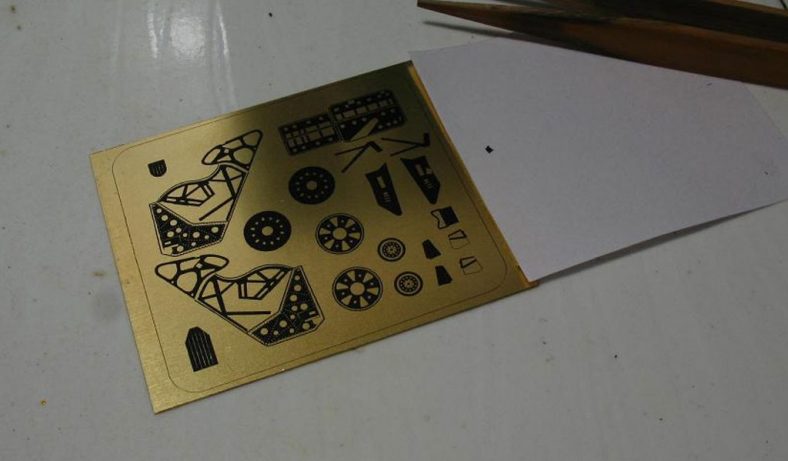

Art Etching

This technique not only provides artists with a unique medium to express their creativity but also facilitates the production of fine art, jewelry, and functional pieces.

-

Diaphragms Etching

A metal diaphragm is a thin, flexible membrane made from metal that responds to changes in pressure, volume, or force. These diaphragms are designed to deform in response to external stimuli, allowing them to transmit mechanical energy or fluid pressure effectively.

-

Automotive Etching

Metal etching is a sophisticated process employed across various sectors, including the automotive industry, to produce intricate designs, patterns, and components with high precision.

-

Decorative Etching

Decorative etching is a versatile and artistic technique employed to create intricate designs and patterns on various materials, predominantly metals and glass.

-

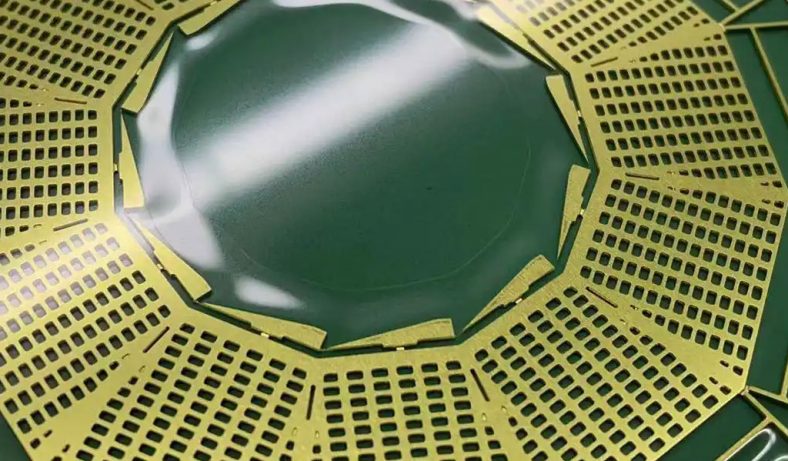

Filter Etching

Filter etching is a specialized technique employed in the manufacturing of filter components used across various industries, including automotive, aerospace, medical, and electronics.

-

Nameplate Etching

Nameplate etching is a specialized process used to create detailed markings, logos, and information on a variety of materials, typically metals or plastics.

-

Military Etching

Military etching refers to the process of creating intricate and precise designs or markings on materials, such as metals, that are used in military applications.

-

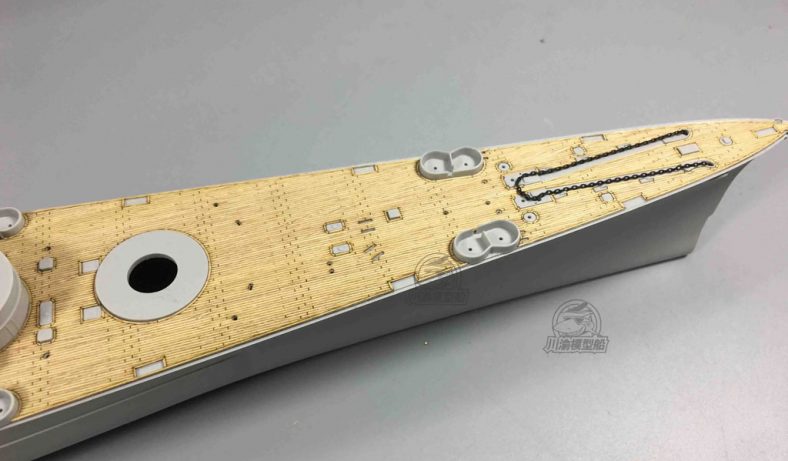

Toy Etching

Toy etching is a specialized form of surface modification that involves the precise removal of material from the surface of a toy using various etching techniques.

-

Energy Etching

Metal etching for energy industries is a crucial technique applied across various sectors, such as renewable energy, fossil fuels, nuclear power, and energy storage, to produce highly precise components used in complex systems.

-

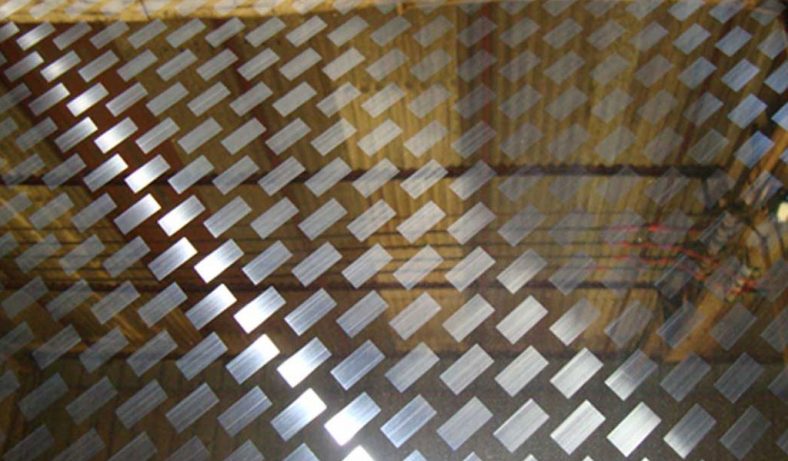

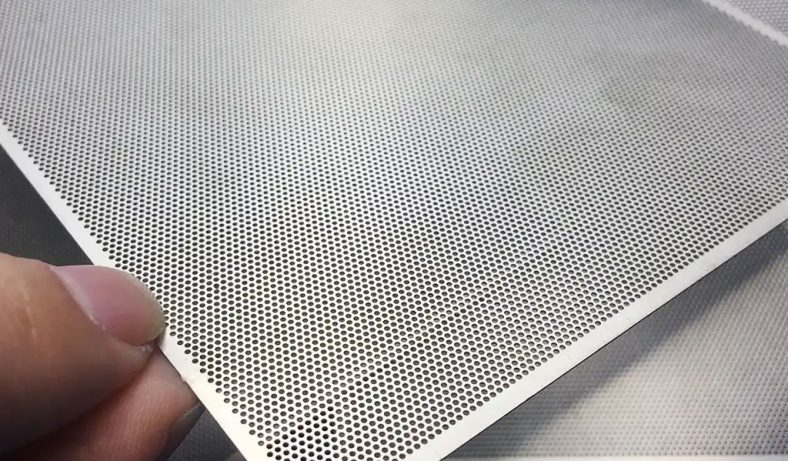

Mesh Etching

Mesh etching refers to the precise process of etching patterns or designs onto mesh materials, which are typically composed of thin, woven, or perforated sheets of metal, plastic, or other materials.

-

Telecom Etching

Telecommunications etching is a highly specialized manufacturing technique used in the production of electronic and communication components, including intricate circuits, antennas, waveguides, filters, and shielding components

-

Nuclear Etching

Metal etching for the nuclear industry involves techniques used to create precise patterns, remove unwanted material, or prepare surfaces for further treatments, all while maintaining the high standards required for safety, reliability, and performance.

-

Batteries Etching

In the context of energy storage devices like batteries and supercapacitors, metal etching is used to manufacture components such as electrodes, current collectors, and other intricate parts that require high precision.