Discover Powerful and Sustainable Stamping Solutions

As a leading precision stamping company in China, Be-Cu Tech focuses on mission-critical applications and invests heavily in automation and technology. We leverage our world-class precision stamping expertise, mould manufacturing capabilities, and engineering traditions to address the industry’s most challenging issues.

Online Metal Stamping Services Across Multiple Industries

Custom metal stamping services for metal parts and rapid production components. Online, you can receive a free, precise stamping quote and design feedback within just a few hours.

Top China Metal Stamping Company

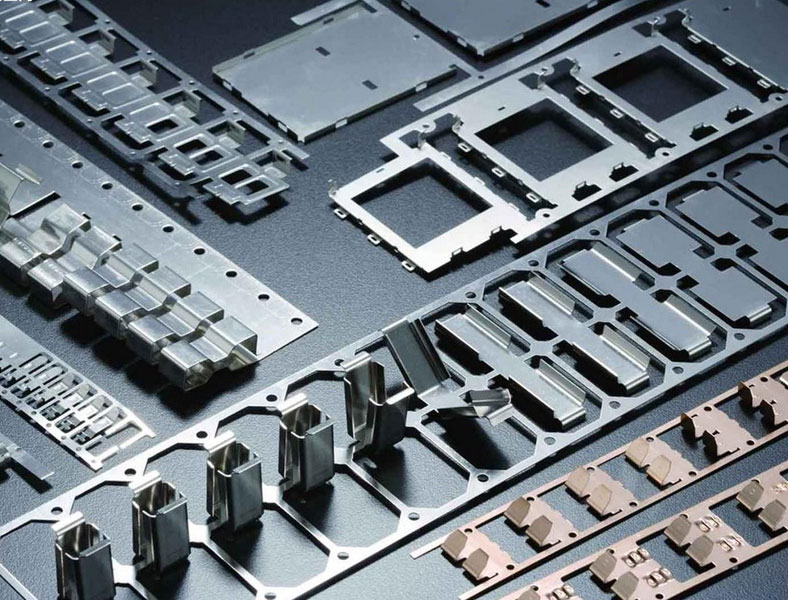

Be-Cu company offers custom stamping services for the production of various products, structures, and components. We provide a wide range of manufacturing processes, including high-speed stamping, deep drawing, punching and blanking, welding, bending, assembly, and laser cutting. Our engineers are capable of punching, rotating, bending, folding, and cutting various sheet metal materials to form virtually any shape.

- Over 30 Years of Stamping Experience

- Our team members bring over 15 years of experience in the LED industry.

- We are well-versed in certifications and registrations, such as IATF and ISO.

- We conduct rigorous inspections to ensure reliable quality for our customers.

- We offer fast delivery within 15 to 30 days.

Why We is Trusted by Over 3,000 Clients

We produce 10 million stamping parts annually and lead the stamping industry in developing technologies that enable the production of more complex shapes, higher densities, and improved dynamic properties. Below are the key benefits of our services:

We are capable of quickly punching a wide range of metal materials and finished products. Be-Cu delivers rapid production while ensuring high precision. Additionally, our high-volume production allows us to offer cost-effective sheet punching services.Capabilities include handling material thickness from .005 in.-.687 in.,Press capacity ranges from 4 tons to 800 tons,blank size of 30 in. x 30 in. maximum, & draws of 8 in. diameter & 3 in. deep maximum,Available in up to +/- 0.0005 tolerance. Coining, continuous, fineblanked, high speed, punch press, forming, and transfer, progressive or compound die stamping methods provided. Stampings are coated, countersunk, cruciform, embossed, flat, strain relief, tapped, and threaded. Prototype and low to high volume production runs available.

Thanks to our advanced stamping technologies, we can produce lightweight yet durable stamping components. All of our stamped products are guaranteed to possess high strength, scratch resistance, and corrosion resistance.

Materials Available for Stamping Parts

Be-Cu offers a wide range of materials for stamping projects, providing metals and superalloys with various strengths, fill levels, stiffness, colours, and other physical, mechanical, and chemical properties. Be-Cu is also known for its high reliability and commitment to on-time delivery. These versatile materials are matched and analysed according to the precise stamping and manufacturing capabilities of each material to meet the specific requirements of your project.

- Stainless Steel

- Aluminium

- Copper

- Magnesium

- Bronze

- Galvanised Steel

- Brass

- Carbon Steel

- And more

Be-Cu’s extensive stamping options are supported by in-house tooling capabilities that adapt tools to suit the unique characteristics of each material. Behind this is a team of engineering experts with over 30 years of experience, adapting to both new alloys and proven materials. For further details, please feel free to contact our engineers.

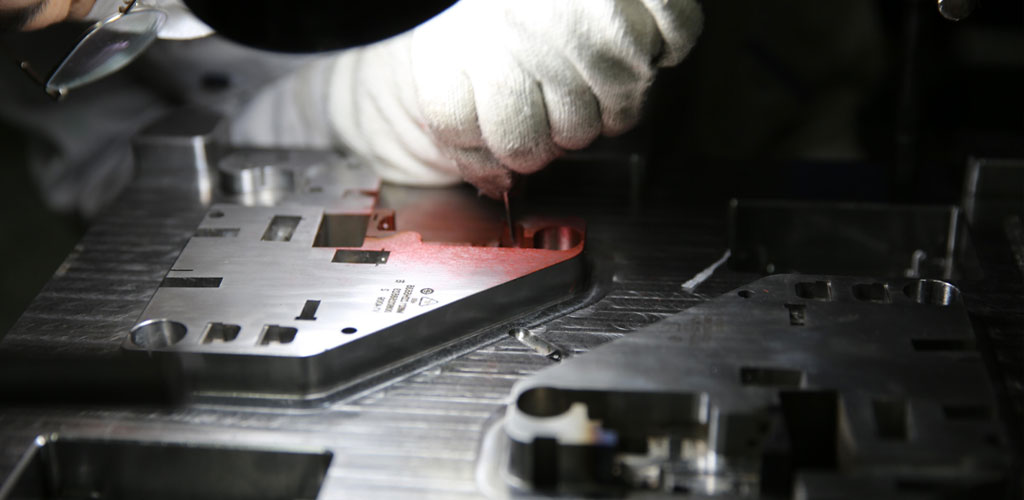

In-House Tool And Mold Room

At BE-CU Metal Stamping company, we design, build and maintain all of our own dies in-house, which helps reduce cost, improve quality, and generate faster turnaround times. Our focus on efficient tooling ensures optimal performance and reduces expenses associated with manufacturing processes.

Additionally, we provide a unique benefit to our customers by offering free repair and maintenance services for all customer dies while the tooling is in our possession. This commitment to exceptional customer service not only saves our customers money but also guarantees that their tooling is expertly cared for, leading to improved efficiency and longevity.

As an ITAF 16949 stamping company, our ongoing commitment to research and development in the stamping field has led us to secure over 20 patents. Be-Cu also maintains comprehensive quality inspection procedures.

Specialising in high-speed stamping, we operate more than 60 high-speed stamping machines, ranging from 25T to 600T, with stamping speeds of up to 600 cycles per minute. The maximum monthly capacity of a single stamping terminal is 3 million pieces and 5 million fragments.

We boast a 10,000-square-metre manufacturing facility and a team of 200 experienced engineers and support staff. Additionally, Be-Cu’s CEO, Famer Li, holds 100% ownership of both a powder coating plant and a medium-sized machining facility.