In the rapidly evolving landscape of modern technology, unmanned systems have emerged as a pivotal player, transforming industries and pushing the boundaries of innovation. From unmanned aerial vehicles (UAVs) to autonomous ground vehicles (AGVs) and unmanned underwater vehicles (UUVs), the applications of unmanned systems are diverse and far-reaching. These systems have revolutionized various sectors, including defense, agriculture, transportation, and surveillance, among others. However, the key to the optimal functioning and performance of these unmanned systems lies in the incorporation of cutting-edge technologies, and etched components have emerged as a critical element in this process.

This comprehensive analysis delves into the role of etched components in enhancing the efficiency, reliability, and overall capabilities of unmanned systems. We will explore the fundamental aspects of etching technology, its applications in the context of unmanned systems, and the myriad benefits it offers. Additionally, we will examine the challenges associated with integrating etched components and highlight the ongoing advancements and future prospects in this rapidly evolving field.

Fundamentals of Etched Components

Before delving into the specific applications in unmanned systems, it is imperative to grasp the fundamentals of etching technology. Etching refers to the process of selectively removing material from the surface of a component to create intricate patterns, designs, or microstructures. This precision manufacturing technique enables the production of complex and miniaturized components with high accuracy and repeatability. The two primary methods of etching—chemical etching and physical etching—play a crucial role in the fabrication of various components used in unmanned systems.

Chemical etching involves the use of corrosive chemicals to dissolve specific areas of a material, leaving behind the desired pattern or structure. On the other hand, physical etching employs physical forces, such as ion beams or plasma, to erode the material’s surface. Both methods offer unique advantages, including high precision, scalability, and the ability to work with a diverse range of materials, including metals, polymers, and semiconductors.

Applications of Etched Components in Unmanned Systems

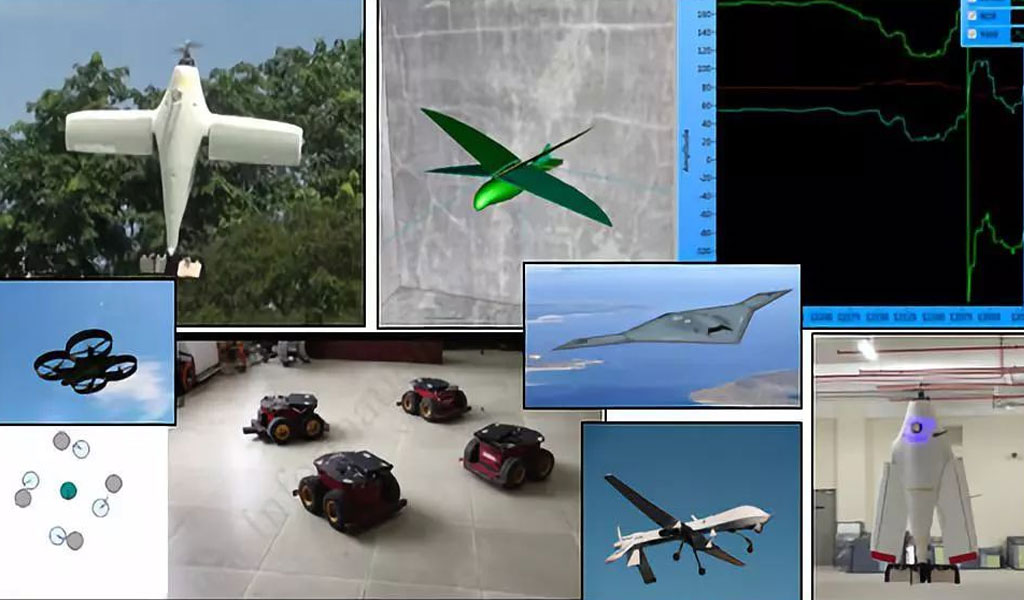

The integration of etched components has significantly enhanced the capabilities of unmanned systems across multiple domains. In the realm of aerospace, etched components have revolutionized the design and manufacturing of UAVs, enabling the production of lightweight yet robust structures that can withstand harsh environmental conditions. The aerospace industry has witnessed a paradigm shift, with the use of etched components leading to improved aerodynamics, reduced fuel consumption, and enhanced maneuverability, thereby expanding the scope of applications for UAVs in surveillance, reconnaissance, and logistics.

Moreover, in the field of robotics and automation, etched components have facilitated the development of sophisticated sensors, actuators, and control systems, empowering AGVs and UUVs with advanced navigation and obstacle detection capabilities. The precise fabrication of microelectromechanical systems (MEMS) through etching has paved the way for the miniaturization of sensors and actuators, enabling unmanned systems to operate in confined spaces and complex environments with heightened precision and efficiency.

Furthermore, the use of etched components has redefined the landscape of autonomous vehicles, playing a pivotal role in the integration of advanced communication systems, radar arrays, and LiDAR sensors. These components have bolstered the reliability and real-time data processing capabilities of unmanned vehicles, facilitating seamless communication and decision-making processes crucial for autonomous navigation and collision avoidance.

Benefits of Etched Components in Unmanned Systems:

The incorporation of etched components in unmanned systems offers a myriad of benefits that have revolutionized their operational capabilities and performance. One of the key advantages is the enhanced miniaturization and lightweight construction, which enables the development of compact and agile unmanned systems capable of navigating through complex terrains and confined spaces with ease. The reduced weight of etched components contributes to improved energy efficiency and extended operational endurance, critical factors for unmanned systems operating in remote or inaccessible locations.

Moreover, the high precision and intricate designs achievable through etching technology result in the production of components with superior mechanical strength and durability. This enhanced robustness allows unmanned systems to withstand extreme conditions, including high temperatures, pressure differentials, and mechanical stress, without compromising their functionality or structural integrity. The reliability and resilience offered by etched components are essential for unmanned systems deployed in mission-critical operations, such as search and rescue missions, disaster management, and military reconnaissance.

Additionally, the scalability and cost-effectiveness of etching processes have streamlined the mass production of complex components, thereby reducing overall manufacturing costs and facilitating the widespread adoption of unmanned systems across various industries. The ability to produce high-quality components in large quantities within a short timeframe has accelerated the pace of technological advancements and fostered the rapid deployment of unmanned systems in commercial applications, such as precision agriculture, infrastructure inspection, and logistics management.

Challenges and Future Prospects

Despite the numerous benefits associated with etched components, several challenges persist in the integration and implementation of this technology in unmanned systems. One of the primary challenges is the requirement for specialized manufacturing facilities and skilled personnel capable of handling complex etching processes, which may pose a barrier for small-scale manufacturers or startups aiming to enter the unmanned systems market. Additionally, the stringent regulatory standards and certification requirements in certain industries, such as aerospace and defense, necessitate comprehensive testing and validation procedures to ensure compliance with safety and quality standards, further adding to the overall production costs and lead times.

However, ongoing research and development efforts are focused on overcoming these challenges and expanding the capabilities of etched components in unmanned systems. Innovations in etching techniques, such as the integration of advanced masking materials and the development of hybrid etching methods, are poised to further enhance the precision and versatility of etched components, enabling the fabrication of more complex and intricate structures with improved mechanical properties and functional capabilities. Furthermore, the convergence of etching technology with other emerging fields, including nanotechnology and 3D printing, holds immense potential for the development of next-generation unmanned systems equipped with multifunctional, smart components that can adapt to dynamic environmental conditions and perform a wide array of tasks with enhanced efficiency and autonomy.

In Conclusion

In conclusion, the pivotal role of etched components in enhancing the performance, reliability, and operational capabilities of unmanned systems cannot be understated. From aerospace and robotics to autonomous vehicles and beyond, etching technology has catalyzed a transformative shift, enabling the development of advanced unmanned systems that are redefining the boundaries of technological innovation and reshaping various industries. The continued advancements in etching techniques, coupled with ongoing research endeavors aimed at addressing existing challenges, are poised to unlock new possibilities and propel the evolution of unmanned systems, fostering a future where autonomous technologies play a central role in driving progress and addressing complex societal challenges. As we embark on this transformative journey, the integration of etched components will remain a cornerstone, paving the way for a future where unmanned systems operate seamlessly, efficiently, and with unparalleled precision, contributing to a safer, more sustainable, and technologically advanced world.