Chemical etching stands as a versatile manufacturing process that has revolutionized the production of intricate and precise components across numerous industries. This article endeavors to delve into the multifaceted world of chemical etching, exploring its costs, the factors influencing pricing structures, its diverse applications, and the comparative advantages it offers over alternative manufacturing techniques.

Material Costs: Substrates and Chemicals

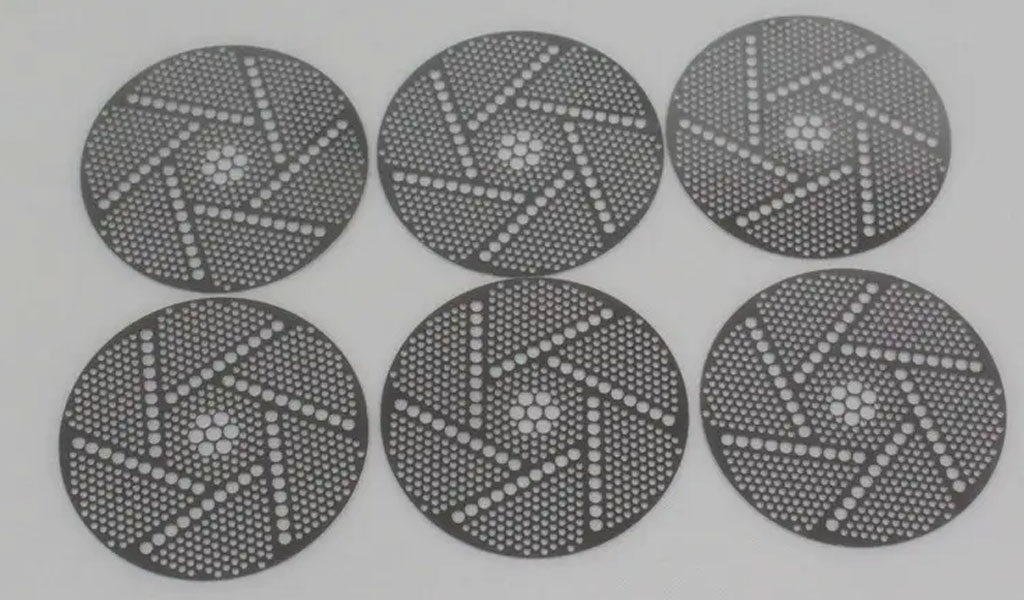

Chemical etching involves the use of various substrates (metallic or non-metallic) and chemicals (etchants) to selectively remove material and create intricate designs.

The costs of these materials can significantly impact the overall expense of the process. Factors influencing material costs include:

- Substrate Material: Different materials (stainless steel, copper, aluminum, etc.) have varying costs per unit area. Exotic or specialized materials might incur higher expenses.

- Chemical Etchants: The type, quality, and volume of etchants required for the process affect costs. Some specialized etchants can be expensive, and their proper disposal might add to overall expenses.

Equipment and Technology Investment

The machinery and technology utilized in chemical etching operations contribute significantly to the overall costs. This includes:

- Etching Equipment: Acid-resistant tanks, spray equipment, conveyor systems, and other machinery necessary for the etching process incur initial procurement costs and ongoing maintenance expenses.

- Technology Upgrades: Regular technological advancements might require periodic upgrades or replacements, impacting operational costs.

Labor Costs and Skill Intensity

The expertise and labor required for chemical etching contribute to its overall cost structure:

- Skilled Workforce: Trained technicians or engineers are needed to operate the machinery, monitor the etching process, handle chemicals safely, and troubleshoot issues. Higher skill levels may command higher salaries.

- Labor Intensiveness: Complex designs or intricate etching requirements might demand more labor hours, subsequently increasing costs.

Volume and Scale of Production

The scale at which chemical etching is performed influences its costs:

- Economies of Scale: Larger production volumes often lead to cost efficiencies due to better resource utilization and reduced per-unit processing costs.

- Setup Costs: Small-batch or prototype runs might incur relatively higher setup costs per unit compared to mass production.

Complexity of Designs and Tolerances

The complexity of the designs and tight tolerances required significantly impacts the cost of chemical etching:

- Design Complexity: Highly intricate or detailed designs may require more precise control, longer processing times, and specialized techniques, increasing overall costs.

- Tolerance Requirements: Tighter tolerances necessitate more precise handling, which can increase costs due to additional quality control measures and specialized equipment.

Quality Control and Inspection Expenses

Maintaining quality standards throughout the etching process incurs additional costs:

- Inspection Equipment: Investing in inspection tools, such as microscopes, profilometers, or optical comparators, adds to the overall expenses.

- Quality Assurance: Regular inspections and quality checks throughout the process are necessary to ensure compliance with specifications, leading to additional labor and time expenses.

Understanding these cost factors is crucial for businesses considering or utilizing chemical etching in their manufacturing processes. Each factor interplays with others, impacting the overall cost structure and efficiency of the chemical etching process.

Comparative Cost Analysis

The comparative cost analysis of chemical etching against traditional machining methods, alternative etching techniques, and the evaluation of long-term cost efficiency and return on investment (ROI):

Chemical Etching vs. Traditional Machining Methods

Chemical etching and traditional machining methods (like milling, turning, drilling) differ significantly in their cost structures:

- Material Waste: Chemical etching is a subtractive manufacturing process, resulting in minimal material wastage compared to traditional methods where excess material is removed.

- Complexity of Designs: Chemical etching excels in producing intricate and highly precise designs with minimal tooling costs compared to traditional machining, which might require specialized tools for complex shapes.

- Setup Costs: Initial setup costs in chemical etching might be higher for tooling and masking, but for intricate designs, traditional machining may incur higher setup expenses.

- Labor and Time Efficiency: Chemical etching can be more time-efficient for mass production once the initial setup is complete. Traditional machining, while versatile, might be labor and time-intensive for intricate designs.

Cost Comparison with Alternative Etching Techniques (Laser, Electrochemical, etc.)

Chemical etching competes with various alternative etching techniques:

- Laser Etching: Laser etching may offer similar precision to chemical etching but might have higher initial equipment costs and consume more energy, impacting operational expenses.

- Electrochemical Etching: While effective for certain applications, electrochemical etching might have limitations in material compatibility and precision compared to chemical etching.

- Cost per Unit: The cost per unit for each technique needs to be evaluated based on specific requirements, material compatibility, and design complexity.

Evaluating Long-Term Cost Efficiency and Return on Investment

Determining the long-term cost efficiency and ROI involves considering multiple factors:

- Total Cost of Ownership (TCO): Calculating the TCO involves analyzing not just the upfront costs but also ongoing operational, maintenance, and disposal expenses associated with each method.

- Scalability and Flexibility: Chemical etching’s scalability and adaptability to varying production volumes without significantly impacting costs can enhance its long-term efficiency.

- Lifecycle Analysis: Conducting a lifecycle analysis helps in understanding the environmental impact, longevity of equipment, and the overall economic feasibility over the long term.

- Market Demand and Technological Advancements: Assessing market trends and technological advancements in etching techniques can impact future costs and ROI.

Comparing these aspects across chemical etching, traditional machining, and alternative etching methods aids businesses in making informed decisions about the most cost-effective approach for their specific manufacturing requirements. Considering not only immediate costs but also long-term efficiency and returns is crucial for optimizing production processes.

Case Studies and Cost Breakdown

Let’s explore case studies involving chemical etching across different industries to understand cost breakdowns and specific applications:

Case Study 1: High-Volume Production in Electronics Industry

Scenario: A company in the electronics industry requires high-volume production of intricate metal parts for smartphones using chemical etching.

Cost Breakdown:

- Material Costs: Medium-cost stainless steel substrates and specialized etchants contribute to 35% of the total expenses.

- Equipment Investment: Initial setup costs for acid-resistant tanks, conveyor systems, and automated etching machinery account for 25%.

- Labor Costs: Skilled technicians operating machinery and overseeing the process constitute 20%.

- Volume Scale Impact: Economies of scale drive down per-unit costs by 15% due to optimized production.

- Quality Control: Inspection equipment and quality checks add to 5% of the total expenses.

Application: Chemical etching proves cost-effective due to high repeatability, low material wastage, and the ability to produce intricate designs required for smartphone components.

Case Study 2: Low-Volume, High-Precision Components for Medical Devices

Scenario: A medical device manufacturer needs low-volume production of intricate, high-precision metal parts using chemical etching.

Cost Breakdown:

- Material Costs: High-cost titanium substrates and specialized etchants constitute 45% of the total expenses.

- Equipment Investment: Initial setup costs for precision etching equipment and cleanroom facilities account for 30%.

- Labor Costs: Highly skilled technicians managing the process and ensuring precision contribute to 20%.

- Volume Scale Impact: Due to low volume, there are minimal economies of scale, leading to higher per-unit costs.

- Quality Control: Rigorous quality checks and compliance testing add to 5% of the total expenses.

Application: Despite higher material costs and less scalability, chemical etching is preferred due to its ability to create intricate, high-precision components critical for medical devices.

Case Study 3: Customized Designs for Automotive Applications

Scenario: An automotive manufacturer requires customized, intricate metal components for high-end vehicles utilizing chemical etching.

Cost Breakdown:

- Material Costs: Medium-cost aluminum substrates and standard etchants constitute 30% of the total expenses.

- Equipment Investment: Initial setup costs for etching equipment with specific masking capabilities account for 20%.

- Labor Costs: Skilled technicians managing the process and ensuring customized designs contribute to 25%.

- Volume Scale Impact: Moderate economies of scale lead to reduced per-unit costs by 15%.

- Quality Control: Stringent quality checks and testing add to 10% of the total expenses.

Application: Chemical etching is preferred due to its ability to create customized, intricate designs and moderate scalability for automotive applications.

These case studies highlight how the cost breakdowns in chemical etching vary across industries based on material choices, volume scalability, equipment investment, labor intensity, and quality control requirements specific to each application.

Future Trends and Cost Implications

The future trends and potential cost implications associated with chemical etching:

Technological Innovations in Chemical Etching

- Microfluidics and Nanotechnology: Continued advancements in microfluidics and nanotechnology are driving the demand for ultra-precise and intricate components. Chemical etching techniques are evolving to cater to these demands, offering enhanced precision and control at the micro and nano scales.

- Advanced Masking Techniques: Innovations in masking technologies are anticipated, enabling more intricate and complex designs while reducing material wastage and processing times.

- Green Chemistry and Sustainable Practices: Future trends will likely emphasize the development of more environmentally friendly etchants and processes, reducing the environmental impact while maintaining or improving cost efficiency.

Impact of Industry 4.0 and Automation on Cost Optimization

- Automation Integration: Industry 4.0 principles integrating automation, IoT (Internet of Things), and AI (Artificial Intelligence) will streamline chemical etching processes, reducing human intervention, minimizing errors, and optimizing resource utilization. This will impact labor costs positively.

- Predictive Maintenance: Predictive maintenance leveraging sensor technology and AI algorithms will minimize downtime and maintenance costs by identifying potential issues before they disrupt operations.

- Data-Driven Decision-Making: Data analytics will play a crucial role in optimizing process parameters, reducing material wastage, and enhancing overall cost efficiency.

Market Projections and Cost Forecasts

- Increased Adoption Across Industries: Projections indicate a growing adoption of chemical etching across various industries, driven by its precision, scalability, and adaptability to diverse materials.

- Cost Reduction Through Economies of Scale: As demand increases, economies of scale will likely drive down material costs and operational expenses, leading to more competitive pricing for chemical etching services.

- Customization and Personalization: The market is expected to see a surge in demand for customized and personalized products, favoring chemical etching due to its ability to cater to intricate and unique designs efficiently.

- Global Market Expansion: With technological advancements and increased awareness of its benefits, the global chemical etching market is expected to expand, potentially driving down costs through increased competition and innovation.

Anticipating these future trends and market projections can aid businesses in strategic planning, investment decisions, and leveraging the evolving landscape of chemical etching to enhance cost-effectiveness and competitiveness in their respective industries.

Conclusion

In conclusion, the cost dynamics of chemical etching encompass a multitude of factors that significantly influence its overall expenses, making it a pivotal aspect in manufacturing processes across diverse industries. Throughout this comprehensive exploration, several key takeaways emerge regarding the costs and implications of chemical etching:

Key Highlights:

- Cost Factors: Material expenses, equipment investment, labor, volume scale, design complexity, and quality control intricately impact the overall cost structure of chemical etching.

- Comparative Analysis: When compared to traditional machining methods and alternative etching techniques, chemical etching demonstrates advantages in material efficiency, precision, and scalability, influencing its cost-effectiveness.

- Case Studies: Varied case studies across industries underline how cost breakdowns differ based on volume requirements, precision needs, material choices, and quality assurance standards, demonstrating the versatility of chemical etching in meeting diverse demands.

- Future Trends: Anticipated technological innovations, integration of Industry 4.0 principles, and market projections highlight the potential for increased efficiency, reduced costs through automation, green chemistry advancements, and expanding market opportunities for chemical etching.

Final Thoughts:

Chemical etching stands as a versatile and efficient manufacturing process that continually evolves to meet the demands of modern industries. Understanding its cost implications, future trends, and market dynamics becomes instrumental in making informed decisions about its utilization in various applications.

As technology advances and industries demand greater precision, customization, and sustainability, chemical etching remains a compelling solution. Its ability to strike a balance between precision, scalability, and cost efficiency positions it as a vital player in the manufacturing landscape, offering unique advantages that continue to shape and drive innovation across sectors.