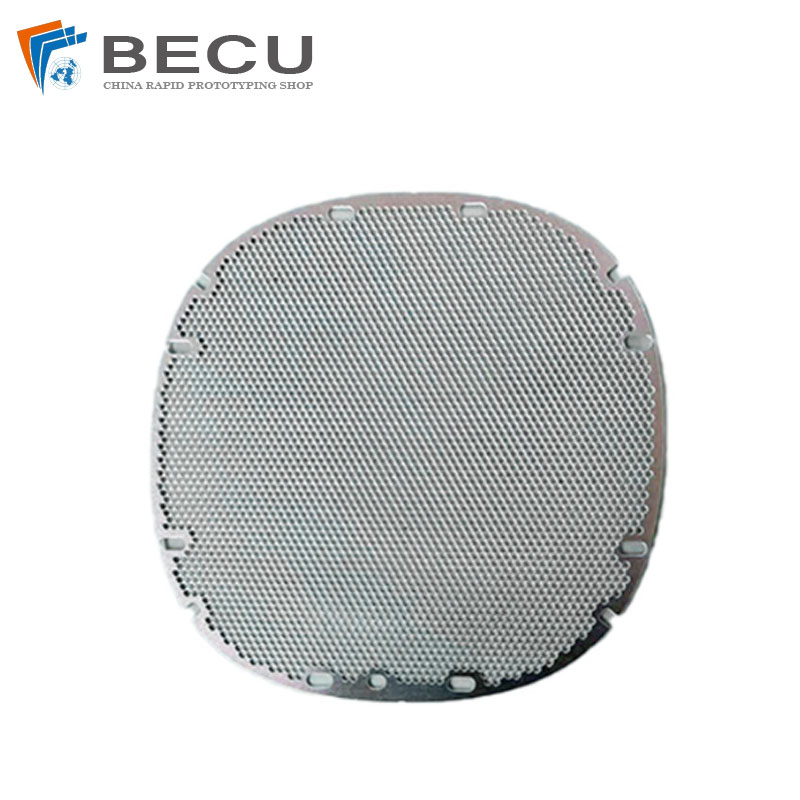

316L Hair Dryer Mesh Etching

- Material: Stainless Steel alloy

- Thickness: 0.5/0.6/0.7 mm

- Project Offer:Within 3 hours

- Process: Precision Etching

- Custom Cycle:Involving Mold Opening, – monthly sample delivery

- Production Capacity:5000-10000PCS/day

- Application: Semiconductor Packaging

- Add Process:Stamping, Self-Owned Hardware Mold Room, Electroplating, Electrophoresis, PVD Vacuum Plating

- Type: Stainless Steel Etching

High-Quality High Speed 316L Hair Dryer Mesh Etching

With the continuous development of household appliance technology, high-speed hair dryers are also undergoing a gradual transformation towards miniaturization and precision. In the segmented market, familiar brands include Dyson, T3, AIRFLY, Babyliss, Panasonic, and others.

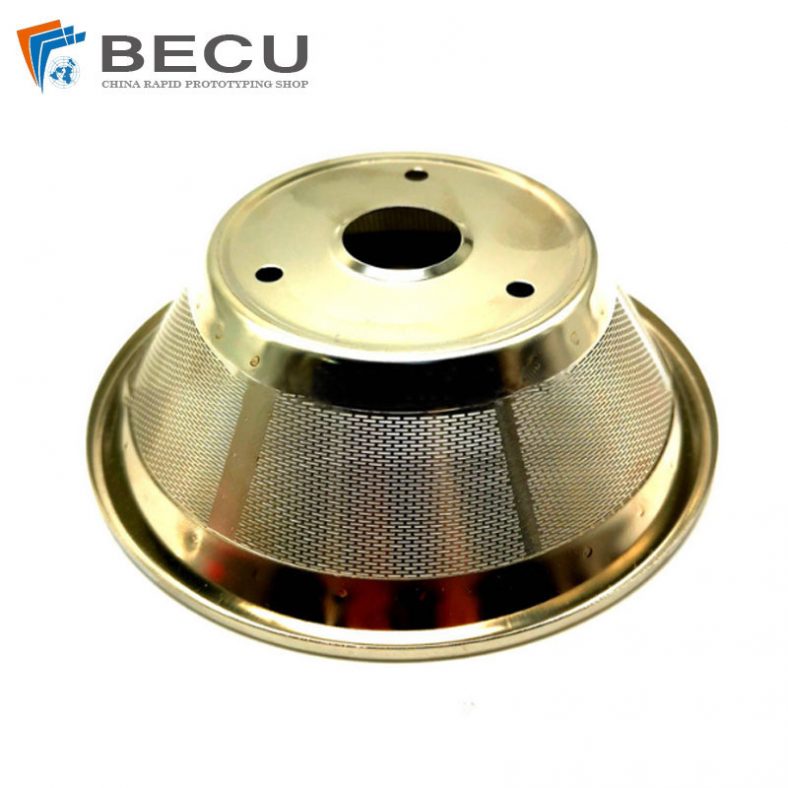

High-speed hair dryers typically consist of a set of heating elements and a high-speed small fan. They are used for drying and styling hair, and also find application in laboratories, therapy rooms, industrial production, and beauty salons for localized drying, heating, and therapy purposes. Hair dryers are generally classified into three types: AC series-excited type, AC shunt type, and DC permanent magnet type.

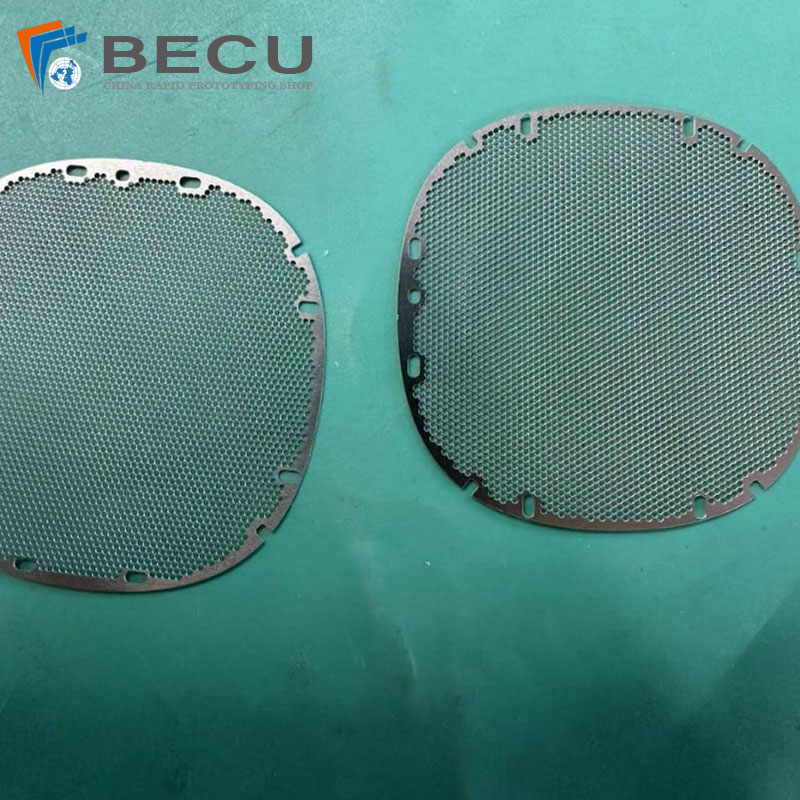

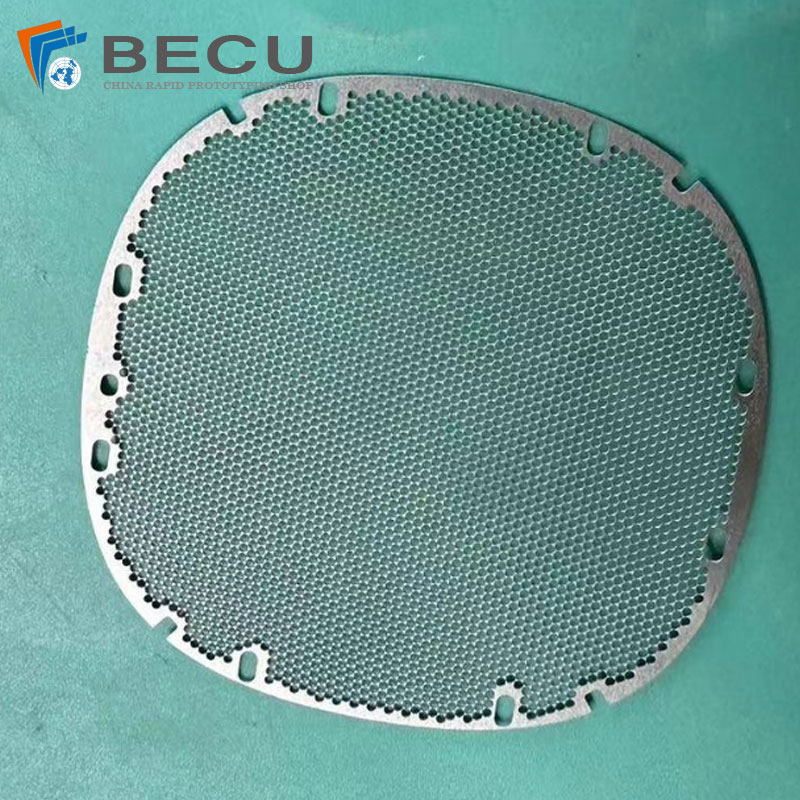

On the nozzle of high-speed hair dryers, there is often a mesh grille that serves both protective and functional purposes. How are these fan grille meshes manufactured? This involves precision technology. Traditional methods involve woven mesh, still used in some hair dryer fans, with surface treatments to enhance durability. However, in high-end hair dryers, the fan grilles are manufactured using an etching process. Etched fan grilles exhibit extremely high precision, with accuracies up to ±0.0075mm, meeting various assembly requirements.

Using metal photo etching allows for flexible design modifications at low cost. The etched fan grilles are uniform, burr-free, and without gaps. The thickness that can be etched ranges from 0.01 mm to 2 mm, and the etching process enables faster iteration speeds and more precise manufacturing of high-speed hair dryer fan grilles.

Why Choose Our High Speed 316L Hair Dryer Mesh Etching Service?

- Etching processing technology is adopted, with high precision, up to ±0.008mm (different thickness of different materials). 15 years of professional precision etching processing factory, the quality is trustworthy.

- The etching process of Be-cu has no restrictions on complex patterns and arbitrary geometric figures. No matter how complicated the hole shape or pattern is, it can be formed in one process without increasing the production cost.

- Be-cu chemical etching is a double-sided simultaneous processing technology. The surface of the product (front and back) is smooth, no bumps, no pits, no burrs, no warping, the mesh is flat and no deformation, no need to polish , Polishing, self-care process after flattening.

- The size of etching process is fine (aperture ≥ 0.1mm, thickness 0.03-2.0mm), and the positioning is accurate (minimum precision ± 0.008) uniform.

- The production cycle is short, the response is fast, and the design is easy to modify. The Be-cu professional etching technology engineering team has a total of 17 people and has senior technicians who have been in the industry for 15+ years.

- Be-cu samples are produced quickly, and samples can be produced within 1-2 working days (determined according to product requirements).

- Be-cu etching has 16 automatic etching production lines, with high etching processing output, which can meet your production orders for batch processing and etching customized microporous mesh.

- Be-cu provides auxiliary services such as stamping, welding, oil spraying, painting, electrophoresis, electroplating, electrolysis, passivation, polishing, stretching, wire drawing, silk screen LOGO, injection molding, etc., to meet the needs of different products and realize convenient and fast — One-stop processing service.

- Be-cu has passed the factory inspections of many well-known companies such as Gree, Joyoung, Xinbao, Xiaomi, Lake and American and German customers. The quality and delivery time are stable, and the customer satisfaction and employee satisfaction are high.

Contact Be Cu Now for your Custom Metal Etching, We are your best online Etching services choice!

Specifications of High Speed 316L Hair Dryer Mesh Etching

| Material Type | Aluminium/Brass/Copper/Nitinol/Stainless steel/Titanium/Kovar |

| Size | Customized |

| Min. Hole Dia. | Dia.≥1.2xT |

| Min. Pitch | D≥1.0xT |

| Tolerance | 0.003mm |

| Material Thickness | T≥0.03mm |

| Process | Etching/Plating/Stamping/Bending/Laser cuting |

| Surface Finish | PVD/Coating/Painting |

| Inspection | IPQC/AQL |

| Packing | Plastic Tray or Customized |