Homepage » Metal Etching »

Titanium Chemical Etching – Titanium Etching

Titanium (Ti) is a transition metal, recognized for its low density and high strength-to-weight ratio. It is highly resistant to corrosion, especially from seawater and chlorine. Titanium alloys, such as Ti-6Al-4V, are extensively used in industries where performance in extreme conditions is critical. However, the same properties that make titanium valuable also make it difficult to process using conventional machining techniques, which is where chemical etching becomes particularly useful.

Titanium chemical etching is a specialized process used to pattern or etch titanium and its alloys through chemical means. This process plays a significant role in various industries, including aerospace, medical, and electronics, due to titanium’s unique properties such as high strength, low density, excellent corrosion resistance, and biocompatibility.

Looking for reliable, quick-turn titanium etching services suppliers and more precision etching product manufacturers? With advance etching line, our unparalleled design and production capacity capabilities guarantee premier OEM titanium etching Parts to worldwide customers.

Our Titanium Plate/Sheet/Roll Etching Service

If you need titanium parts etched we are one of the most capable and affordable sources specializing in manufacturing custom etched parts on advanced photo etching machines with cnc precision. Through our Photo Chemical Etching process, the smallest and most complex designs are made possible such as electrical spring contacts, contact membranes, busbars, antennae and micro antennae, spring fingered contacts, heating elements and battery terminal as well as many other bespoke components to your own designs.

We can machine to print and accept the most common file formats including: .dwg .dxf .iges .step .sat as well as .pdf files. If you don’t see your file format here let us know. Please send us files to: [email protected] We can accept both small and large run jobs of custom titanium etching parts.

Our Etching Capabilities

- Etching of many grades of Titanium, including TZM,MHC,Mo-La,Mo-Cu and more

- Combining Stamping, Laser Cutting,CNC machining and photochemical etching on sheets up to 2mm thick

- Etching of up to 0.025″ thick sheets as large as 22×12 inches

- Tolerances of ±.0005″ in many applications

How To Etch Titanium

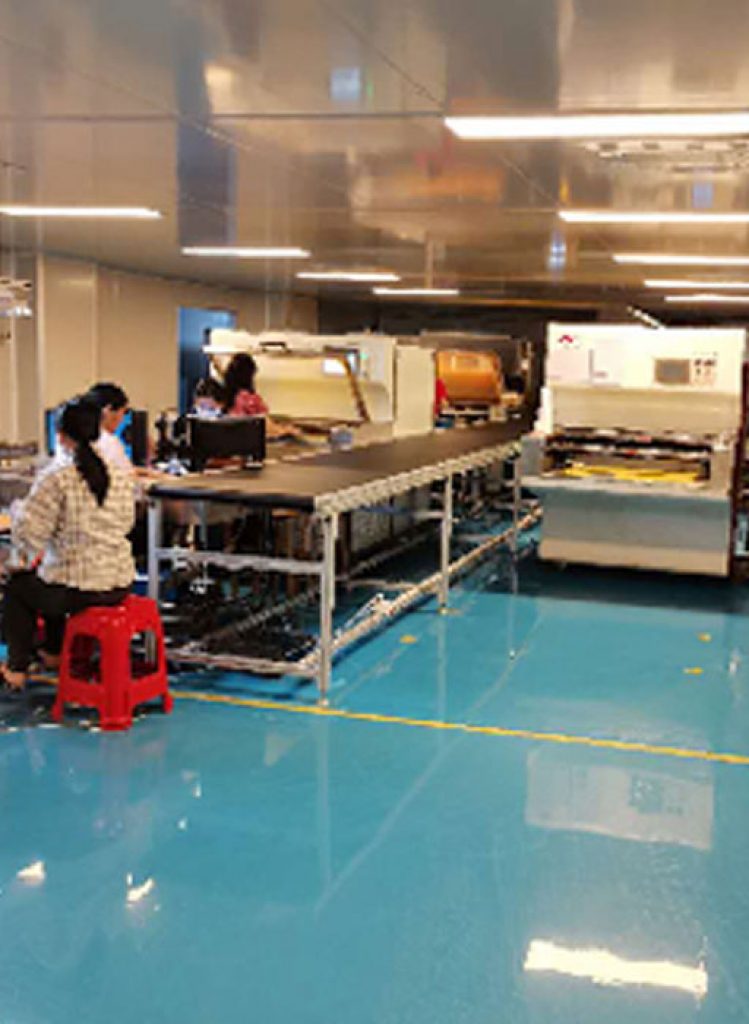

Automated-Coating

Automatic-Baking-Line

Automatic-Shearing

Coating-For-Etching-Parts

Deinking

Etching

Exposure

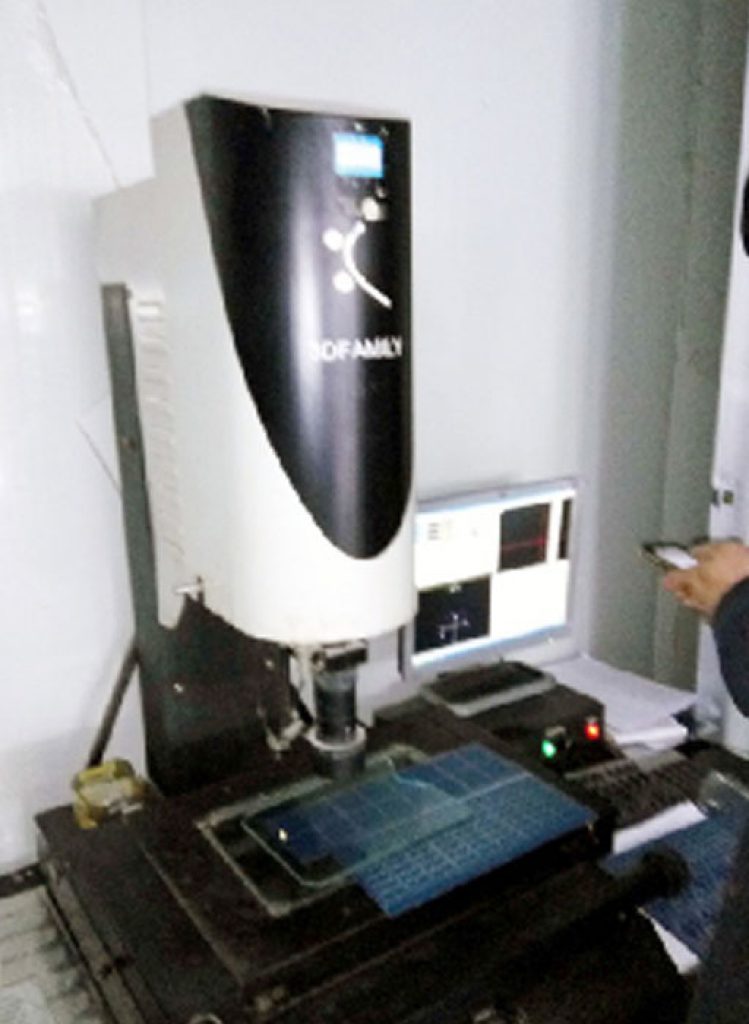

Inspection-For-Etching

Metal Grades For Titanium Etching

Titanium etching requires careful consideration of the specific titanium grade being used. The choice of titanium grade affects the etching process, including the selection of etchants, etching conditions, and the final properties of the etched components. BE-CU ETCH offers precision etching with multiple titaniumm alloys.Below are some of the common grades of titanium used in etching applications, each with its unique properties and suitable applications:

Commercially Pure Titanium Etching

Commercially pure titanium is available in four grades, each with varying amounts of impurities. These grades are characterized by their excellent corrosion resistance, biocompatibility, and moderate strength.

- Grade 1: The softest and most ductile of the commercially pure titanium grades. It is easy to form and weld, making it suitable for applications requiring good corrosion resistance and high ductility. Typical applications include chemical processing equipment, marine environments, and medical devices.

- Grade 3: Higher strength than Grades 1 and 2, but slightly less ductile. It is used in applications requiring higher mechanical properties, such as industrial and aerospace applications.

- Grade 2: The most widely used of the commercially pure titanium grades. It offers a good balance of strength, ductility, and weldability. Common applications include aerospace components, chemical processing, and medical implants.

- Grade 4: The strongest of the commercially pure titanium grades. It provides excellent corrosion resistance and good formability. Applications include medical implants, industrial equipment, and aerospace components.

Titanium Alloys Etching

Titanium alloys are developed to enhance specific properties, such as strength, heat resistance, and toughness. These alloys typically contain elements like aluminum, vanadium, and tin.

Ti-6Al-4V (Grade 5)

Applications: Aerospace components, medical implants, marine applications, and high-performance automotive parts.

Etching Considerations: Ti-6Al-4V requires more aggressive etchants and precise process control due to its alloying elements, which can affect the etching rate and pattern resolution.

Ti-6Al-4V ELI (Grade 23)

Applications: Medical implants, surgical instruments, and other biomedical devices.

Etching Considerations: Similar to Grade 5, but the lower impurity levels may provide more consistent etching results.

Ti-3Al-2.5V (Grade 9)

Applications: Aerospace tubing, sports equipment, and industrial applications.

Etching Considerations: Requires specific etching parameters to manage the alloying elements and achieve uniform etching.

Ti-5Al-2.5Sn (Grade 6)

Applications: Aerospace components, heat exchangers, and pressure vessels.

Etching Considerations: The presence of tin requires adjustments in the etching process to ensure uniformity and precision.

Ti-6Al-2Sn-4Zr-2Mo (Grade 6-2-4-2)

Applications: Aerospace engine components, high-temperature structural applications.

Etching Considerations: Requires careful control of etching conditions due to the presence of multiple alloying elements.

Ti-15V-3Cr-3Sn-3Al (Grade 15-3-3-3)

Applications: Aerospace components, springs, and fasteners.

Etching Considerations: Beta alloys like this one may require different etching solutions and parameters compared to alpha or alpha-beta alloys.

Components That Are Produced By Etching Titanium

The popularity of titanium makes it a desirable metal for use in fabrication because it is easy to manufacture and has favorable properties for many industrial products.With the photo etching process, the metal is etched evenly without any structural deformations from the hard tooling used in stamping and punching.Since there isn’t a heat point of contact like laser cutting, the parts’ metal properties remain unchanged and free from thermal deformations.Get inspired by our custom etching part projects and contact us to Get Instant Quote for rapid prototype or titanium etching parts start from 1pcs.

-

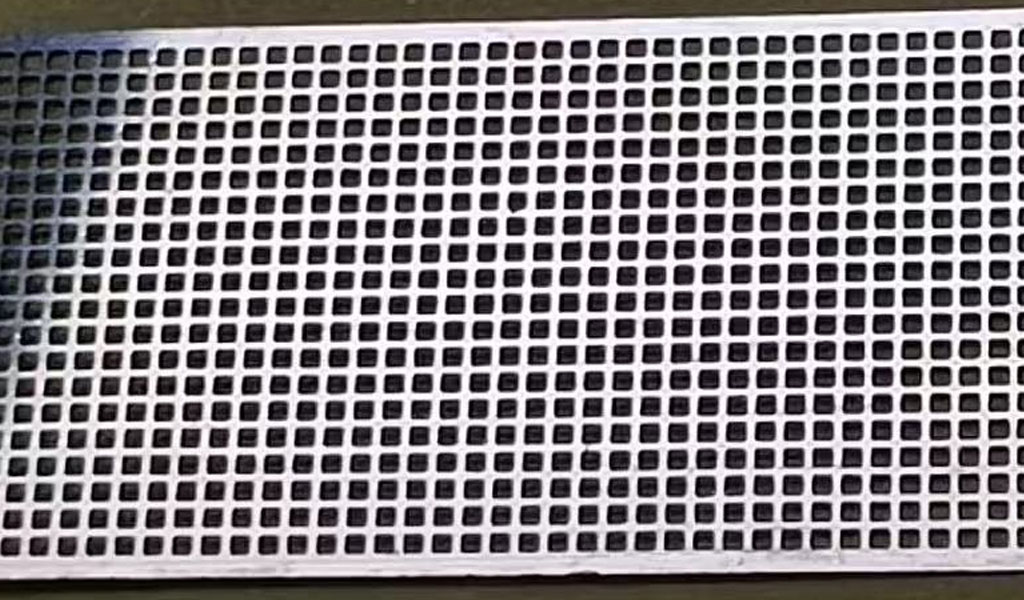

Precision Etched Titanium Alloy Odor Eliminator Perforated Plates

-

High-End Etched TC4 Titanium Alloy Filters

-

Precision Etching Titanium Alloy Hanging Fixture for Anodizing

-

Metal Chemical Etching Reciprocating Razor Blades

-

Titanium Alloy Etched Coffee Filter

-

Etching Bipolar Plates for Hydrogen Fuel Production

-

0.3MM Laser Etched Titanium Mesh

-

Precision Etching Printer Single Drum Scraper

Metal Etching Certification,Equipment List and Quality

We are committed to enlisting the full support of all employees to continuously improve our processes and enhance quality, thereby fulfilling our customer's needs with defect free products and services, on time and every time

- ISO 9001:2015 certified

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process FMEA

- Fully compliant with the exacting requirements of our customers

- ITAR registered

- NIST cybersecurity standard compliant

- Proprietary Patented quality systems

- Skilled in KanBan and other customer driven quality and inventory management systems

Metal Etching Material

BE-CU is experienced in precision etching various metals, allowing customers the freedom to specify components in hundreds of different materials.

The Surface Treatment Of Metal Etching Parts

Do you want your etching parts to be more corrosion-resistant or get a specific look? Metal finishing service is a essential choice to achieve your design perfectly. BE-CU – metal-etch.com is an accomplished finished parts manufacturer, our workers and craftsman are capable to provide precision metal etching services and a wide range of finishing services including aluminum anodizing, painting, passivation, electroplating, powder coating, polishing, black oxide, conversion coating, abrasive blasting, etc. We offers several common surface finishes to help improve functionality and aesthetics.

- Anodizing (Anodized)

- Passivation

- Plating (Electroplating)

- Painting

- Black Oxide (Hot Blackening)

- Polishing

- Powder Coating

- Heat Treatment

- Satin Finish

- Abrasive blasting (Sandblasting)

- Conversion coating

- Tungsten carbide coating

After browsing a list of metal finishing services, select a process based on essential considerations, like production time, cost-effectiveness, part tolerance, durability and applications. High-tolerance metal etching parts are not recommended to apply secondary metal surface finish, because the treatment may change the sizes of the finished part through removing or adding a small amount of materials.

Other requirements or custom designs, welcome to contact us for a free quote fast!