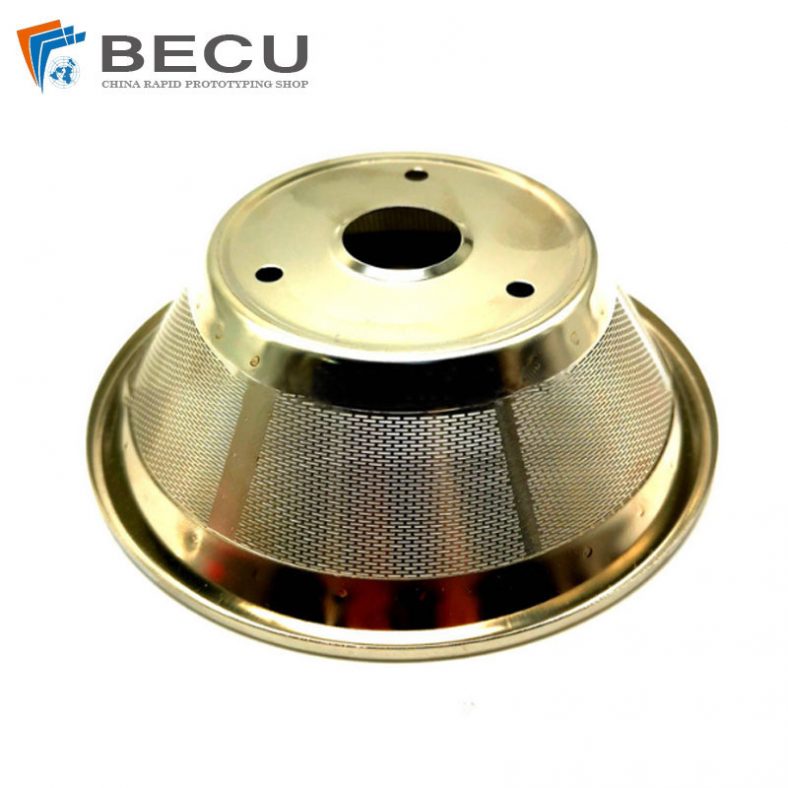

Iron Candlestick

- Material: Iron

- Thickness: 0.5/0.6/0.7 mm

- Project Offer:Within 3 hours

- Process: Precision Etching

- Custom Cycle:Involving Mold Opening, – monthly sample delivery

- Production Capacity:5000-10000PCS/day

- Application: Art

- Add Process:Stamping, Self-Owned Hardware Mold Room, Electroplating, Electrophoresis, PVD Vacuum Plating

- Type: Art and LED Light

High-Quality Three-Dimensional Etching Iron Candlestick

Three-dimensional etching in metalwork, particularly on iron candlesticks, represents a fascinating intersection of art, history, and technology. This decorative technique, which involves the intricate removal of material to create detailed patterns and images, has been used for centuries to enhance the aesthetic appeal of functional objects. Iron candlesticks, serving both practical and ornamental purposes, have been a prime canvas for this form of art. This article explores the history, techniques, cultural significance, and modern applications of three-dimensional etching on iron candlesticks.

The history of metalworking dates back to ancient civilizations, where metals such as gold, silver, and bronze were used to create both utilitarian and decorative objects. Iron, known for its strength and durability, became a popular material during the Iron Age (circa 1200 BCE). Early metalworkers developed various techniques to manipulate iron, including forging, casting, and engraving.

Etching as a technique is believed to have originated in the Islamic world around the 9th century. Early artisans used acid or other corrosive substances to etch intricate designs into metal surfaces. This method allowed for greater detail and precision compared to traditional engraving techniques, where designs were manually carved into the metal.

Candlesticks have been used since ancient times to hold candles and provide lighting. Early examples, dating back to ancient Egypt and Rome, were simple and functional. Over time, candlesticks evolved into more elaborate forms, reflecting the artistic styles and cultural influences of their respective periods. By the medieval period, candlesticks had become significant decorative items in both religious and domestic settings.

The use of etching on iron candlesticks began to gain prominence during the Renaissance period (14th to 17th century). This era, characterized by a renewed interest in art and craftsmanship, saw the development of more sophisticated metalworking techniques. Artisans began to experiment with three-dimensional etching, creating candlesticks that were not only functional but also works of art.

Why Choose Our Three-Dimensional Etching Iron Candlestick Service?

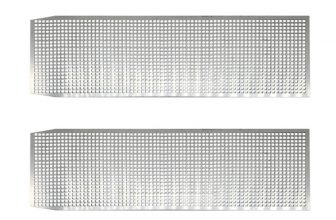

- Etching processing technology is adopted, with high precision, up to ±0.008mm (different thickness of different materials). 15 years of professional precision etching processing factory, the quality is trustworthy.

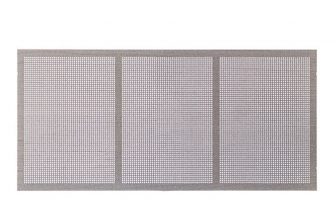

- The etching process of Be-cu has no restrictions on complex patterns and arbitrary geometric figures. No matter how complicated the hole shape or pattern is, it can be formed in one process without increasing the production cost.

- Be-cu chemical etching is a double-sided simultaneous processing technology. The surface of the product (front and back) is smooth, no bumps, no pits, no burrs, no warping, the mesh is flat and no deformation, no need to polish , Polishing, self-care process after flattening.

- The size of etching process is fine (aperture ≥ 0.1mm, thickness 0.03-2.0mm), and the positioning is accurate (minimum precision ± 0.008) uniform.

- The production cycle is short, the response is fast, and the design is easy to modify. The Be-cu professional etching technology engineering team has a total of 17 people and has senior technicians who have been in the industry for 15+ years.

- Be-cu samples are produced quickly, and samples can be produced within 1-2 working days (determined according to product requirements).

- Be-cu etching has 16 automatic etching production lines, with high etching processing output, which can meet your production orders for batch processing and etching customized microporous mesh.

- Be-cu provides auxiliary services such as stamping, welding, oil spraying, painting, electrophoresis, electroplating, electrolysis, passivation, polishing, stretching, wire drawing, silk screen LOGO, injection molding, etc., to meet the needs of different products and realize convenient and fast — One-stop processing service.

- Be-cu has passed the factory inspections of many well-known companies such as Gree, Joyoung, Xinbao, Xiaomi, Lake and American and German customers. The quality and delivery time are stable, and the customer satisfaction and employee satisfaction are high.

Contact Be Cu Now for your Custom Metal Etching, We are your best online Etching services choice!

Specifications of Three-Dimensional Etching Iron Candlestick

| Material Type | Aluminium/Brass/Copper/Nitinol/Stainless steel/Titanium/Iron |

| Size | Customized |

| Min. Hole Dia. | Dia.≥1.2xT |

| Min. Pitch | D≥1.0xT |

| Tolerance | 0.003mm |

| Material Thickness | T≥0.03mm |

| Process | Etching/Plating/Stamping/Bending/Laser cuting |

| Surface Finish | PVD/Coating/Painting |

| Inspection | IPQC/AQL |

| Packing | Plastic Tray or Customized |