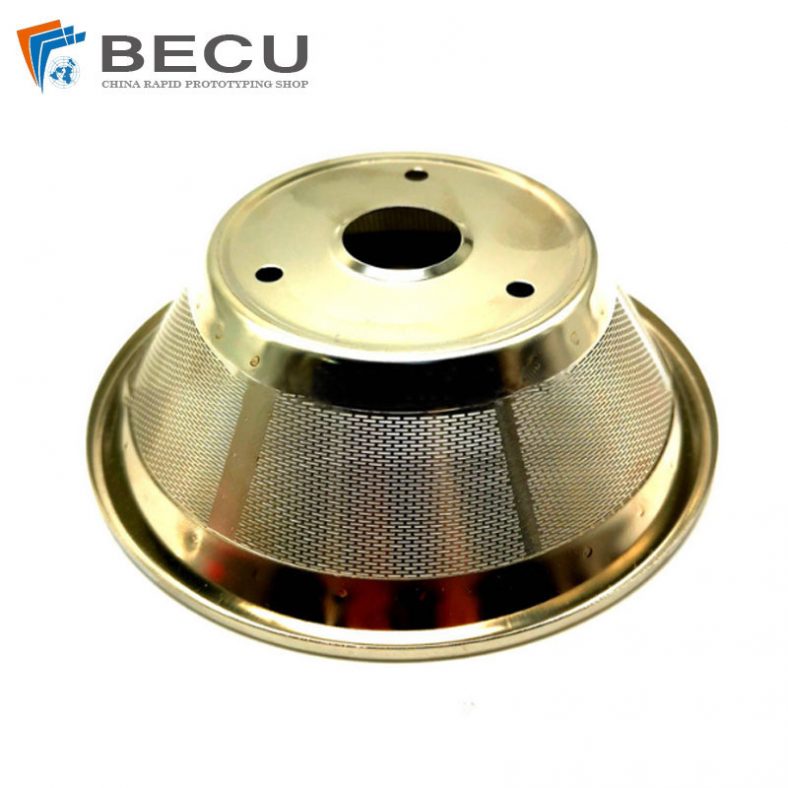

Stainless Steel Juicer Filter

- Material: Stainless Steel

- Thickness: 0.5/0.6/0.7 mm

- Project Offer:Within 3 hours

- Process: Precision Etching

- Custom Cycle:Involving Mold Opening, – monthly sample delivery

- Production Capacity:5000-10000PCS/day

- Application: Juicer Filter

- Add Process:Stamping, Self-Owned Hardware Mold Room, Electroplating, Electrophoresis, PVD Vacuum Plating

- Type: Stainless Steel Etching

High-Quality Precision Etched Stainless Steel Juicer Filter

Precision etching is a critical process in the manufacturing of various components across multiple industries, including the food and beverage sector. One of the most significant applications of precision etching is in the production of stainless steel juicer filters. These filters play a vital role in the juicing process, ensuring that the final product is free from pulp and other unwanted solids.

Stainless steel is an alloy primarily composed of iron, with a minimum of 10.5% chromium content by mass. This composition confers several beneficial properties to the material, including resistance to corrosion, high strength, and excellent durability. These characteristics make stainless steel an ideal choice for juicer filters, as they come into direct contact with acidic fruit juices and need to maintain their integrity over time.

The most commonly used grades of stainless steel for juicer filters include 304 and 316. Grade 304 stainless steel is known for its good corrosion resistance and is widely used in food processing applications. Grade 316 stainless steel offers even better corrosion resistance due to its molybdenum content, making it particularly suitable for applications involving more aggressive substances. The selection of stainless steel grade directly impacts the filter’s performance, longevity, and suitability for specific juicing applications.

Why Choose Our Precision Etched Stainless Steel Juicer Filter Service?

- Etching processing technology is adopted, with high precision, up to ±0.008mm (different thickness of different materials). 15 years of professional precision etching processing factory, the quality is trustworthy.

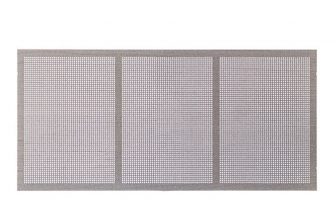

- The etching process of Be-cu has no restrictions on complex patterns and arbitrary geometric figures. No matter how complicated the hole shape or pattern is, it can be formed in one process without increasing the production cost.

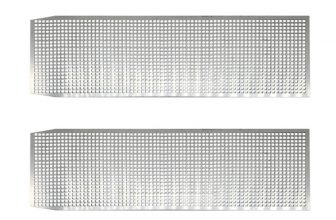

- Be-cu chemical etching is a double-sided simultaneous processing technology. The surface of the product (front and back) is smooth, no bumps, no pits, no burrs, no warping, the mesh is flat and no deformation, no need to polish , Polishing, self-care process after flattening.

- The size of etching process is fine (aperture ≥ 0.1mm, thickness 0.03-2.0mm), and the positioning is accurate (minimum precision ± 0.008) uniform.

- The production cycle is short, the response is fast, and the design is easy to modify. The Be-cu professional etching technology engineering team has a total of 17 people and has senior technicians who have been in the industry for 15+ years.

- Be-cu samples are produced quickly, and samples can be produced within 1-2 working days (determined according to product requirements).

- Be-cu etching has 16 automatic etching production lines, with high etching processing output, which can meet your production orders for batch processing and etching customized microporous mesh.

- Be-cu provides auxiliary services such as stamping, welding, oil spraying, painting, electrophoresis, electroplating, electrolysis, passivation, polishing, stretching, wire drawing, silk screen LOGO, injection molding, etc., to meet the needs of different products and realize convenient and fast — One-stop processing service.

- Be-cu has passed the factory inspections of many well-known companies such as Gree, Joyoung, Xinbao, Xiaomi, Lake and American and German customers. The quality and delivery time are stable, and the customer satisfaction and employee satisfaction are high.

Contact Be Cu Now for your Custom Metal Etching, We are your best online Etching services choice!

Specifications of Precision Etched Stainless Steel Juicer Filter

| Material Type | Aluminium/Brass/Copper/Nitinol/Stainless steel/Titanium |

| Size | Customized |

| Min. Hole Dia. | Dia.≥1.2xT |

| Min. Pitch | D≥1.0xT |

| Tolerance | 0.003mm |

| Material Thickness | T≥0.03mm |

| Process | Etching/Plating/Stamping/Bending/Laser cuting |

| Surface Finish | PVD/Coating/Painting |

| Inspection | IPQC/AQL |

| Packing | Plastic Tray or Customized |