Shielding Electronics Playing Cards

- Material: Copper

- Thickness: 0.5/0.6/0.7 mm

- Project Offer:Within 3 hours

- Process: Precision Etching

- Custom Cycle:Involving Mold Opening, – monthly sample delivery

- Production Capacity:5000-10000PCS/day

- Application: Cards

- Add Process:Stamping, Self-Owned Hardware Mold Room, Electroplating, Electrophoresis, PVD Vacuum Plating

- Type: Stainless Steel Etching

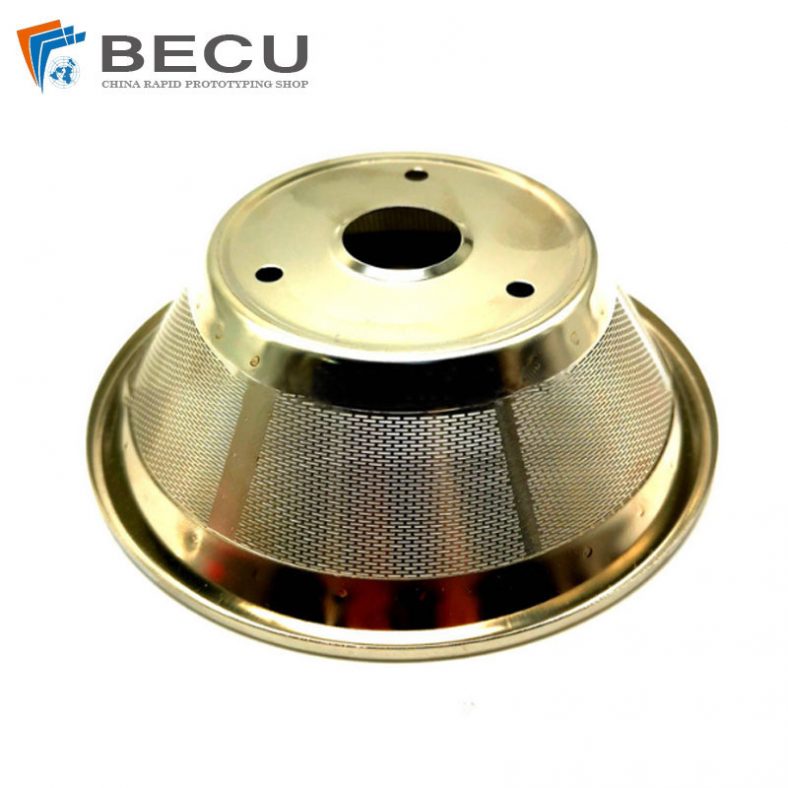

High-Quality Artistic Etched Copper Shielding Electronics Playing Cards

In the rapidly evolving world of electronics, the demand for innovative solutions that combine functionality with aesthetic appeal has never been greater. Our Artistic Etched Copper Shielding Electronics Playing Cards with Patterns service stands at the forefront of this technological renaissance, offering a unique blend of artistry and engineering excellence.

Copper shielding is a critical component in the design and manufacture of electronic devices, providing essential protection against electromagnetic interference (EMI) and ensuring the integrity of signal transmission. Recognizing the importance of both form and function, our service elevates traditional copper shielding to new heights by incorporating intricate, artistically etched patterns. These patterns are not merely decorative; they are meticulously designed to enhance the performance and durability of the shielding while adding a touch of elegance and sophistication.

Our state-of-the-art etching process utilizes advanced techniques to create precise, detailed patterns on copper surfaces. This process involves the use of high-quality materials and cutting-edge technology to ensure that each playing card meets the highest standards of quality and reliability. The result is a product that not only excels in its primary role of shielding electronics but also serves as a testament to the beauty of engineering.

The applications of our Artistic Etched Copper Shielding Electronics Playing Cards are vast and varied. From consumer electronics to industrial equipment, our products are designed to meet the diverse needs of modern technology. Whether you are looking to enhance the performance of a high-end audio system, protect sensitive medical equipment, or add a unique aesthetic touch to a custom electronic device, our service offers a solution that is both practical and visually stunning.

At the heart of our service is a commitment to innovation and excellence. Our team of skilled engineers and artists work closely with clients to develop custom designs that meet their specific requirements. We understand that each project is unique, and we strive to deliver products that exceed expectations in both functionality and appearance.

In conclusion, our Artistic Etched Copper Shielding Electronics Playing Cards with Patterns service represents a fusion of art and technology, offering a sophisticated solution for the modern world of electronics. By combining the protective qualities of copper shielding with the beauty of artistic etching, we provide a product that is as visually appealing as it is functionally superior. Join us in redefining the boundaries of electronic design and experience the perfect harmony of form and function.

Why Choose Our Artistic Etched Copper Shielding Electronics Playing Cards Service?

- Etching processing technology is adopted, with high precision, up to ±0.008mm (different thickness of different materials). 15 years of professional precision etching processing factory, the quality is trustworthy.

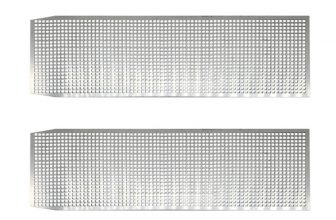

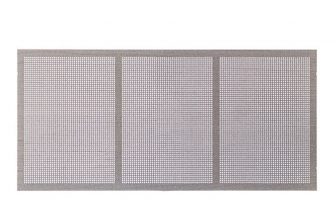

- The etching process of Be-cu has no restrictions on complex patterns and arbitrary geometric figures. No matter how complicated the hole shape or pattern is, it can be formed in one process without increasing the production cost.

- Be-cu chemical etching is a double-sided simultaneous processing technology. The surface of the product (front and back) is smooth, no bumps, no pits, no burrs, no warping, the mesh is flat and no deformation, no need to polish , Polishing, self-care process after flattening.

- The size of etching process is fine (aperture ≥ 0.1mm, thickness 0.03-2.0mm), and the positioning is accurate (minimum precision ± 0.008) uniform.

- The production cycle is short, the response is fast, and the design is easy to modify. The Be-cu professional etching technology engineering team has a total of 17 people and has senior technicians who have been in the industry for 15+ years.

- Be-cu samples are produced quickly, and samples can be produced within 1-2 working days (determined according to product requirements).

- Be-cu etching has 16 automatic etching production lines, with high etching processing output, which can meet your production orders for batch processing and etching customized microporous mesh.

- Be-cu provides auxiliary services such as stamping, welding, oil spraying, painting, electrophoresis, electroplating, electrolysis, passivation, polishing, stretching, wire drawing, silk screen LOGO, injection molding, etc., to meet the needs of different products and realize convenient and fast — One-stop processing service.

- Be-cu has passed the factory inspections of many well-known companies such as Gree, Joyoung, Xinbao, Xiaomi, Lake and American and German customers. The quality and delivery time are stable, and the customer satisfaction and employee satisfaction are high.

Contact Be Cu Now for your Custom Metal Etching, We are your best online Etching services choice!

Specifications of Artistic Etched Copper Shielding Electronics Playing Cards

| Material Type | Aluminium/Brass/Copper/Nitinol/Stainless steel/Titanium |

| Size | Customized |

| Min. Hole Dia. | Dia.≥1.2xT |

| Min. Pitch | D≥1.0xT |

| Tolerance | 0.003mm |

| Material Thickness | T≥0.03mm |

| Process | Etching/Plating/Stamping/Bending/Laser cuting |

| Surface Finish | PVD/Coating/Painting |

| Inspection | IPQC/AQL |

| Packing | Plastic Tray or Customized |