Homepage » Metal Etching »

Etching Stainless Steel – Stainless Steel Etching

Precision Etching is one of the most versatile manufacturing processes available today. This process is compatible with various materials.Stainless Steel is among the most popular material choices for metal etching applications. Precision Etching stainless steel alloys provide manufacturers huge flexibility for product manufacturing.

However, narrowing down your options when it comes to stainless steel etching can be daunting.

Stainless steel is highly resistant to corrosion and rust, making it suitable for situations where a part may be exposed to the elements for a long period of time.

Stainless steel is also fairly malleable and ductile. Be-Cu etch offers multiple stainless steel alloys precision etching service, including a food-safe variety.

Our Stainless Steel Etching Service

we BE-CU ETCH offer professional precision stainless steel etching service that is processes including of photo etching, acid etching, stamping,stamping,,laser cutting,EDM, plus anodizing surface treatment, to make any custom design parts with high-precision dimension based your mechanical engineering drawings.

our etching stainless steel service helps global customers to managetheir operations and custom parts more efficiently. We have rich experienceengineers to reduce labor & machining costs by cutting out time-consumingmanual tasks and automating repetitive tasks, that helps to improve profitmargin and save lead time for our valuable customers.

our etching stainless steel service is not just limited to large volumeorders, it’s no MOQ to produce small order which start from 1 pcs as fast as3 days.

Our Etching Capabilities

- Etching of many grades of stainless steel, including 304, 316, 420, 719, 17-4 PH, 2205, 4130, and 5510

- Combining Stamping, Laser Cutting,CNC machining and photochemical etching on sheets up to 2mm thick

- Etching of up to 0.025″ thick sheets as large as 22×12 inches

- Tolerances of ±.0005″ in many applications

How To Etch Stainless Steel

Automated-Coating

Automatic-Baking-Line

Automatic-Shearing

Coating-For-Etching-Parts

Deinking

Etching

Exposure

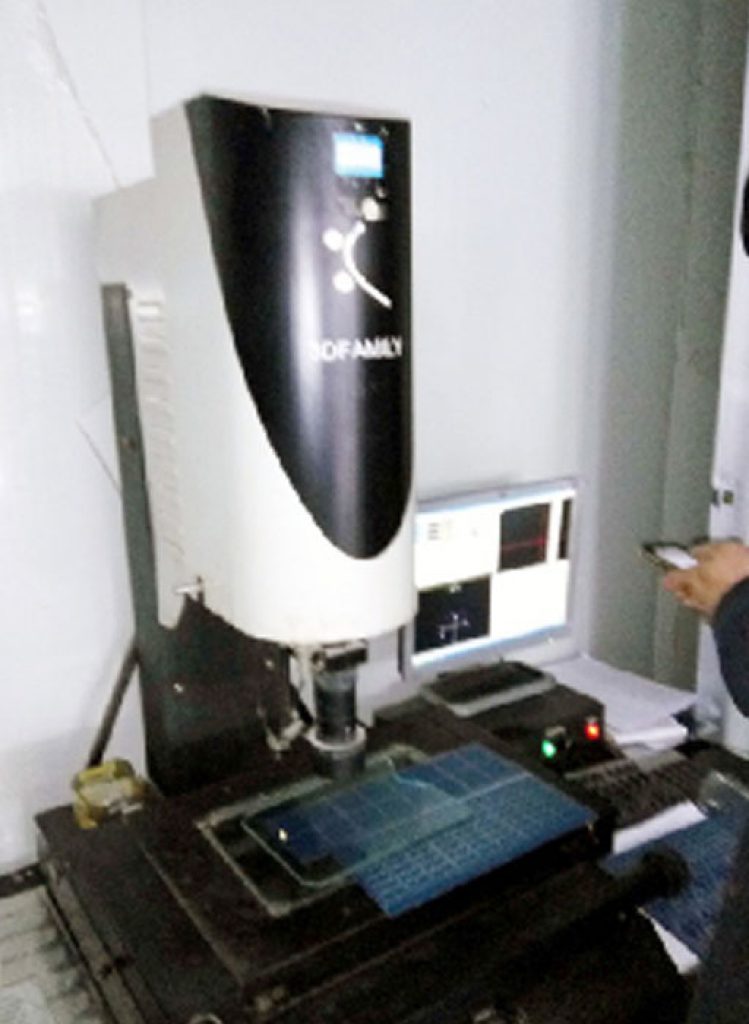

Inspection-For-Etching

Metal Grades For Stainless Steel Etching

Stainless steel etching involves selectively removing material from a stainless steel surface using an etchant, typically an acid, to create designs, patterns, or markings. The choice of material grade and its properties can have a significant impact on the etching process. Different grades of stainless steel have varying corrosion resistance, mechanical properties, and etchability.Here are some common stainless steel grades and their properties:

304 Stainless Steel

Properties: Good corrosion resistance, excellent formability, and moderate strength. It’s a popular choice for etching due to its ease of workability.

316 Stainless Steel

Properties: Superior corrosion resistance, especially in harsh environments. It may be more challenging to etch due to its increased resistance to chemical attacks.

430 Stainless Steel

Properties: Less corrosion-resistant than 304 or 316 stainless steel, but it’s often used in applications where corrosion resistance is not the primary concern. It’s relatively easy to etch.

420 Stainless Steel

Properties: It’s a martensitic stainless steel with good hardness and wear resistance. It can be etched but may require more aggressive etchants.

17-4 PH Stainless Steel

Properties: Known for its high strength and hardness, it’s more difficult to etch compared to austenitic stainless steels.

More Stainless Steel

(7C27Mo2, 13C26, 12C27, 6C27), Hiflex,Uddeholm strip flapper valve steel).

When etching stainless steel, you will need to choose an appropriate etchant and process parameters, such as etchant type, concentration, temperature, and etching time, based on the specific grade of stainless steel you are working with. The choice of resist materials (used to protect the areas you don’t want to etch) and the etching method (e.g., chemical or electrochemical etching) will also play a crucial role in achieving the desired results.

Components That Are Produced By Etching Stainless Steel

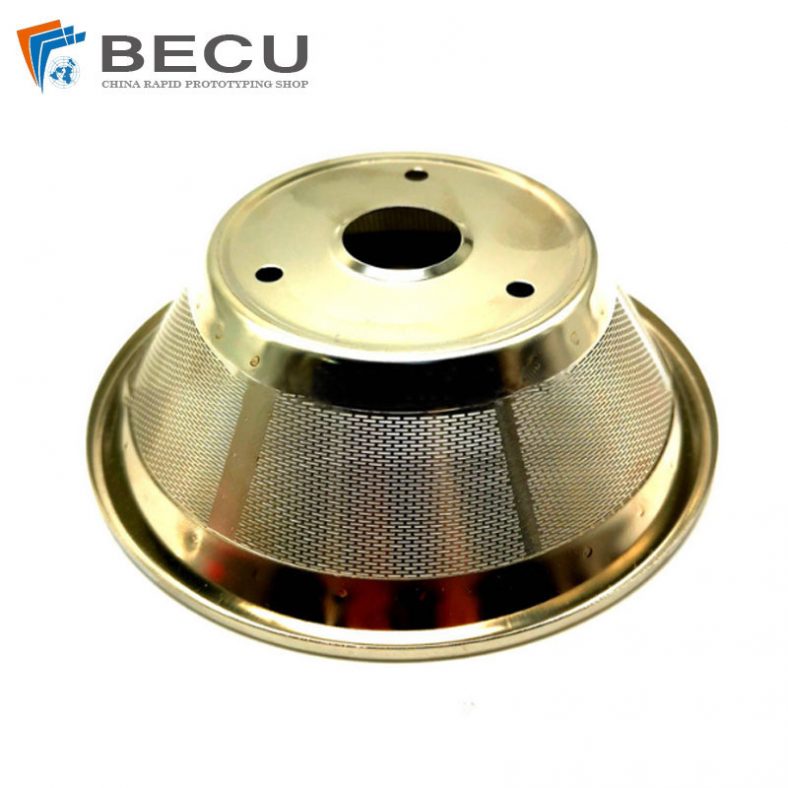

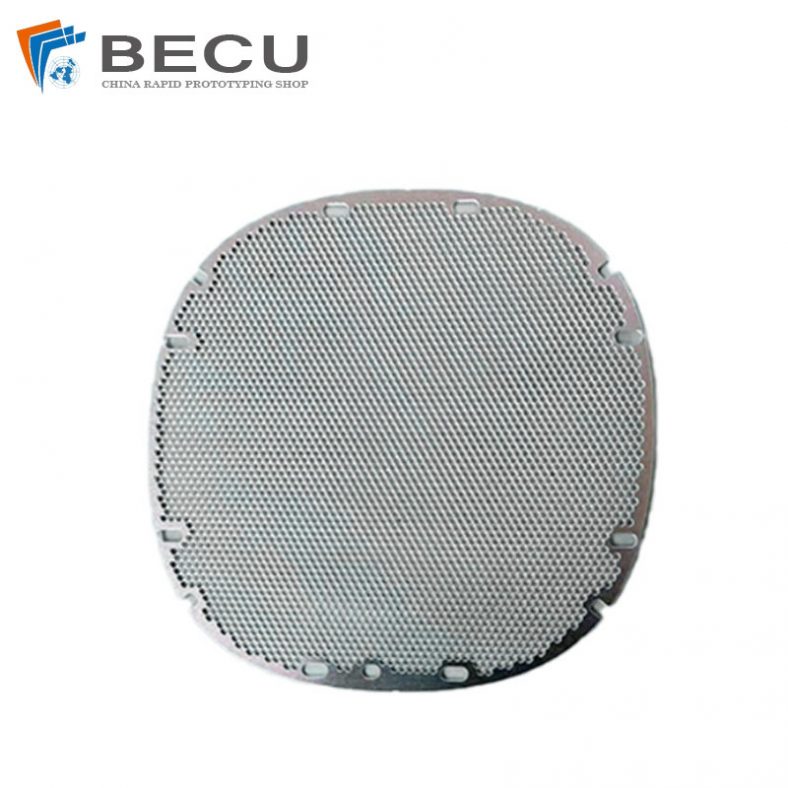

The popularity of stainless steel makes it a desirable metal for use in fabrication because it is easy to manufacture and has favorable properties for many industrial products.With the photo etching process, the metal is etched evenly without any structural deformations from the hard tooling used in stamping and punching.Since there isn’t a heat point of contact like laser cutting, the parts’ metal properties remain unchanged and free from thermal deformations.Get inspired by our custom etching part projects and contact us to Get Instant Quote for rapid prototype or stainless steel etching parts start from 1pcs.

-

Stainless Steel 316L Etching Tea Strainer

-

Russian Mythology Character Metal Nameplate Badge Etching

-

Precision Etching Stainless Steel Juicer Filter

-

3D Etched Special-Shaped Stainless Steel 304 Spinning Lampshade

-

430 Stainless Steel Photoelectric Encoder Code Disc Etching

-

Stainless Steel 304 Wedge Filter Etching

-

High Speed 316L Hair Dryer Mesh Etching

-

Metal Etched Stainless Steel 304 Insect Screen

-

Chemical Etched Stainless Steel 304 Tea Screen Filter

-

Stainless Steel 316 Metal Etched Paring Planer

-

Microporous Etching Stainless Steel 17-4 ph Speaker Mesh

-

Metal Etching Stainless Steel 430 Hair Dryer Air Outlet Net

-

Electric KN95 Mask Breathing Valve Filter

-

Precision Etched Fuel Injector Nozzle Filter

-

Stainless Steel Etching Black Vacuum Blower Plate

-

0.2mm Etched High Speed Hair Dryer Mesh

Metal Etching Certification,Equipment List and Quality

We are committed to enlisting the full support of all employees to continuously improve our processes and enhance quality, thereby fulfilling our customer's needs with defect free products and services, on time and every time

- ISO 9001:2015 certified

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process FMEA

- Fully compliant with the exacting requirements of our customers

- ITAR registered

- NIST cybersecurity standard compliant

- Proprietary Patented quality systems

- Skilled in KanBan and other customer driven quality and inventory management systems

Metal Etching Material

BE-CU is experienced in precision etching various metals, allowing customers the freedom to specify components in hundreds of different materials.

The Surface Treatment Of Metal Etching Parts

Do you want your etching parts to be more corrosion-resistant or get a specific look? Metal finishing service is a essential choice to achieve your design perfectly. BE-CU – metal-etch.com is an accomplished finished parts manufacturer, our workers and craftsman are capable to provide precision metal etching services and a wide range of finishing services including aluminum anodizing, painting, passivation, electroplating, powder coating, polishing, black oxide, conversion coating, abrasive blasting, etc. We offers several common surface finishes to help improve functionality and aesthetics.

- Anodizing (Anodized)

- Passivation

- Plating (Electroplating)

- Painting

- Black Oxide (Hot Blackening)

- Polishing

- Powder Coating

- Heat Treatment

- Satin Finish

- Abrasive blasting (Sandblasting)

- Conversion coating

- Tungsten carbide coating

After browsing a list of metal finishing services, select a process based on essential considerations, like production time, cost-effectiveness, part tolerance, durability and applications. High-tolerance metal etching parts are not recommended to apply secondary metal surface finish, because the treatment may change the sizes of the finished part through removing or adding a small amount of materials.

Other requirements or custom designs, welcome to contact us for a free quote fast!