AMB Etching

- Material: AMB Ceramics

- Thickness: 0.5/0.6/0.7 mm

- Project Offer:With in 3 hours

- Process: Precision Etching

- Custom Cycle:Involving Mold Opening, – monthly sample delivery

- Production Capacity:5000-10000PCS/day

- Application: Electronic

- Add Process: Electroplating, Electrophoresis, PVD Vacuum Plating

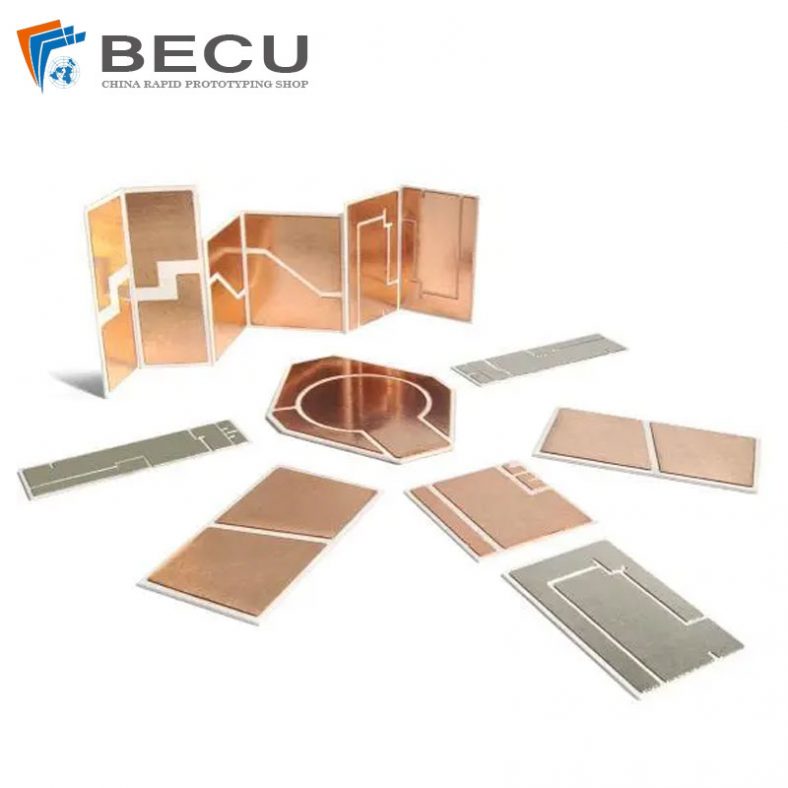

- Type: Ceramics Etching

Alumina Multi-Layered Boards (AMB) are innovative materials that have garnered significant attention in the field of electronics manufacturing, offering a range of notable advantages. Manufacturing AMB boards involves certain technical challenges; however, your company appears to possess the corresponding capabilities for producing ceramic substrates, copper circuitry, and soldering processes, which could bring new opportunities to the electronics industry.

Advantages of AMB Structure Ceramic Substrates

- Multilayer Design: The AMB structure allows for the integration of multiple electronic components and circuits across different ceramic layers. This multilayer design enhances device integration, reduces the size of circuit boards, thus improving performance and functionality.

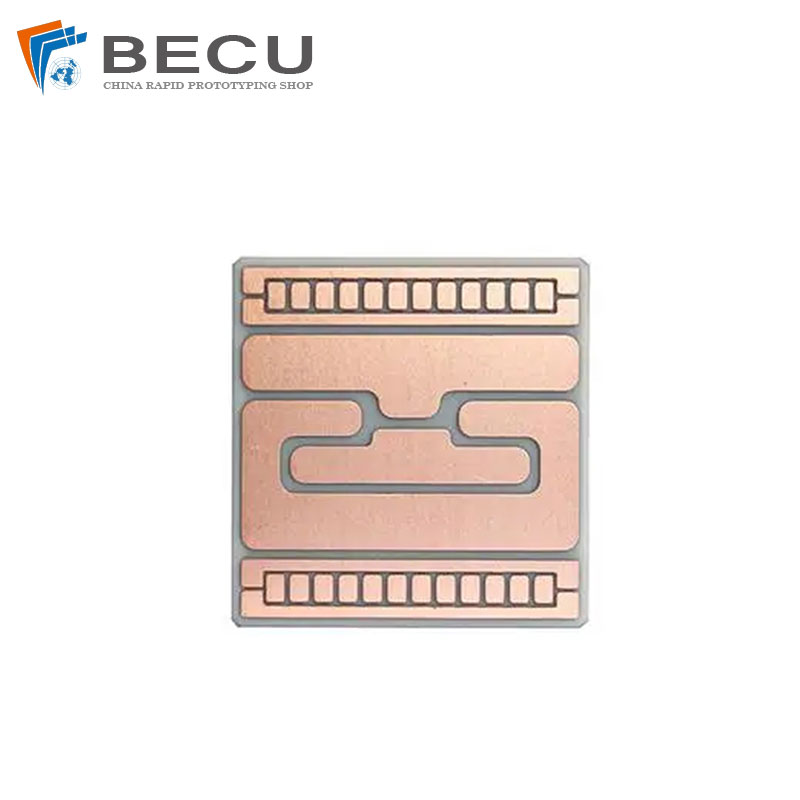

- Excellent Electrical Performance: AMB structure ceramic substrates exhibit outstanding electrical properties, including low capacitance and low loss. This makes them highly suitable for high-frequency and microwave applications, aiding in reducing signal interference and enhancing device performance.

- Superior Thermal Performance: AMB structure ceramic substrates possess excellent thermal conductivity, effectively dissipating and distributing heat. This is crucial for high-power and high-temperature applications, helping to maintain device temperature within a controllable range.

- Mechanical Strength: The multilayer structure makes AMB substrates more robust, capable of withstanding greater mechanical stress and impact. This makes them suitable for harsh environmental conditions, such as military and aerospace sectors, ensuring device reliability and durability.

Challenges in AMB Board Manufacturing

Manufacturing ceramic substrates with AMB structures requires high levels of process technology and strict quality control. Some of these challenges include:

- Material Selection: Choosing suitable ceramic materials and ensuring their quality and uniformity is the first step in manufacturing AMB structure substrates. This requires a deep understanding of ceramic material properties.

- Multilayer Stacking: Integrating electronic components and circuits at different levels requires precise stacking and alignment processes to ensure accurate connections between layers.

- Copper Circuit Fabrication: Fabricating copper circuits involves first creating fine copper wires on ceramic substrates, which requires high-precision processes and equipment.

- Soldering Process: Soldering process is a crucial task in electronic manufacturing to ensure correct component connections and reliability. This requires high technical expertise and precise control to avoid soldering defects and connection issues.

With your company’s existing capabilities in producing AMB structure ceramic substrates, copper circuitry, and soldering processes, you can explore more market opportunities, catering to diverse electronic application fields, and providing high-performance and reliable solutions. These technological advantages will contribute to driving innovation and development in the electronics industry, offering more possibilities for future electronic products.

Market Advantages Of Alumina Multi-Layered Board

- Excellent Insulation Performance: AMB ceramic substrates exhibit outstanding insulation performance, making them ideal substrate materials for electronic devices. This insulation capability reduces interference between electronic components, enhancing device stability and performance.

- High Temperature Stability: Ceramic substrates can operate in high-temperature environments, which is crucial for many applications such as automotive electronics, aerospace, and energy sectors. AMB ceramic substrates can operate reliably in high-temperature conditions, ensuring the reliability of electronic devices.

- Exceptional Mechanical Strength: These substrates have high mechanical strength, capable of withstanding vibration and impact, which is essential for applications requiring high reliability, such as military communications and medical equipment.

- Versatility: Ceramic substrates can be customized according to different requirements, including different shapes, sizes, and thicknesses. This flexibility makes them suitable for various applications, from packaging to circuit boards.

Market Scope Of Alumina Multi-Layered Board

- Telecommunications Industry: AMB ceramic substrates have wide applications in the telecommunications industry, especially in radio frequency (RF) and microwave applications. They are used to manufacture high-performance antennas, filters, and power amplifiers to meet the growing communication demands.

- Automotive Electronics: With the rise of autonomous driving technology and electric vehicles, there is an increasing demand for ceramic substrates in the automotive electronics sector. They are used to manufacture electronic modules with high-temperature stability to support advanced automotive systems.

- Medical Equipment: In the field of medical equipment, AMB ceramic substrates are used to manufacture high-frequency medical devices such as ultrasound probes and magnetic resonance imaging (MRI) systems. Their insulation performance and reliability are crucial for these applications.

- Military and Aerospace: The military and aerospace sectors demand high performance and reliability. The mechanical strength and high-temperature stability of ceramic substrates make them an ideal choice for manufacturing equipment such as radar systems and missile control units in these fields.

Why Choose Our Etching Alumina Multi-Layered Board Service?

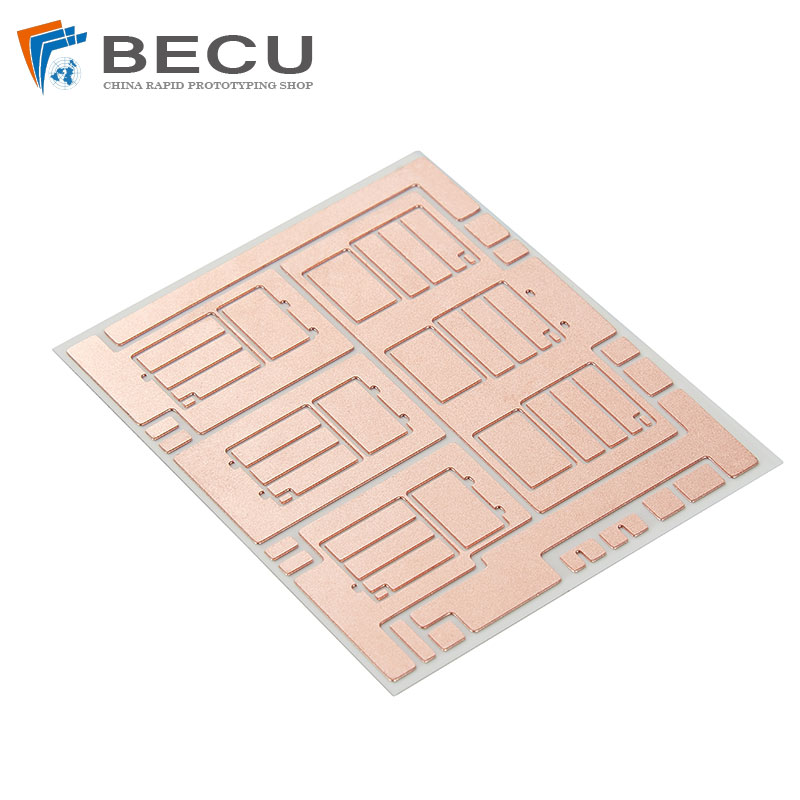

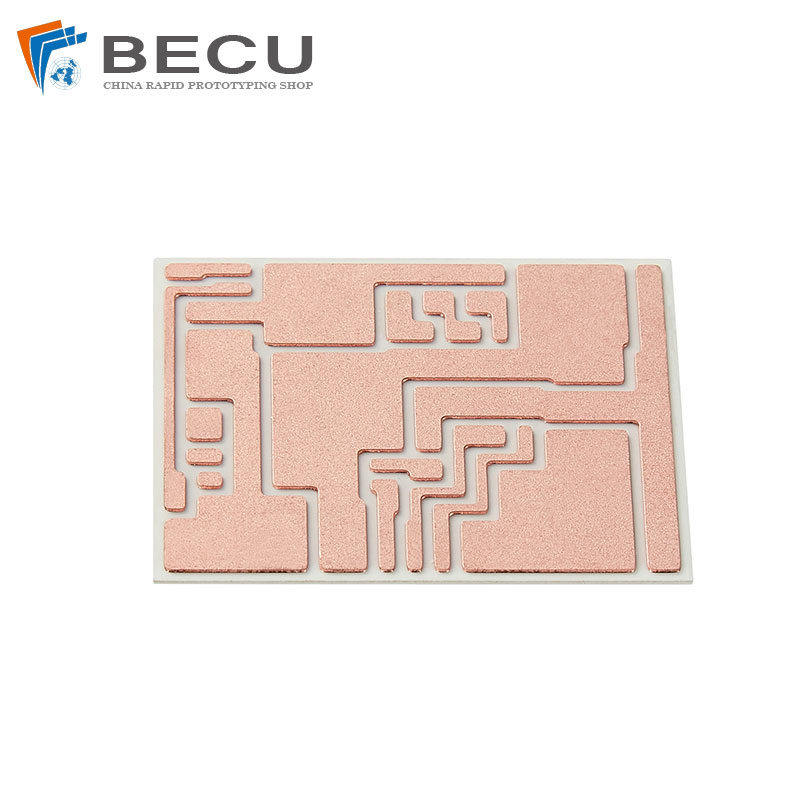

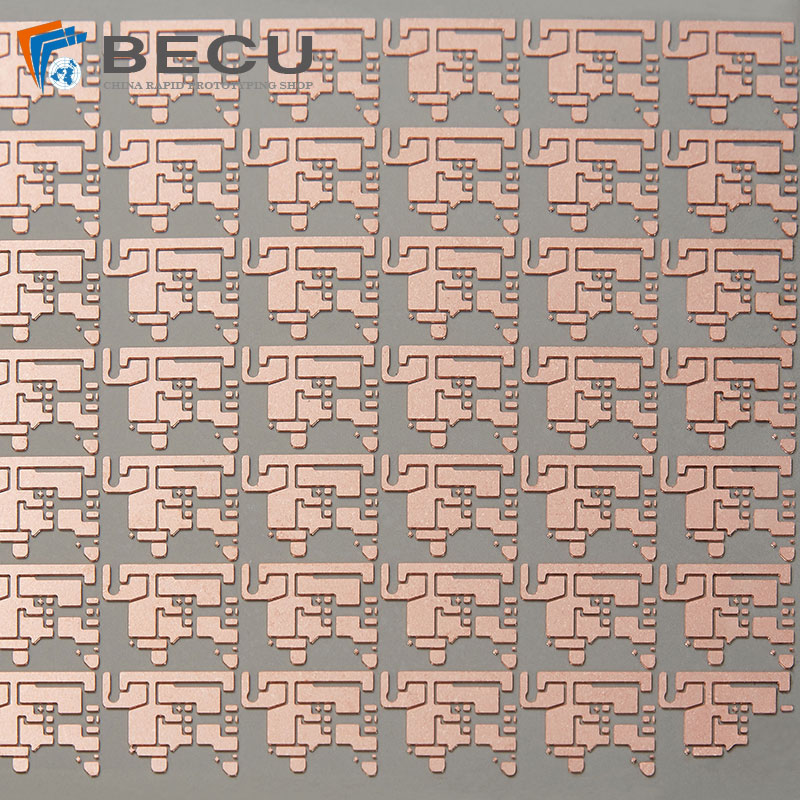

- Etching processing technology is adopted, with high precision, up to ±0.008mm (different thickness of different materials). 15 years of professional precision etching processing factory, the quality is trustworthy.

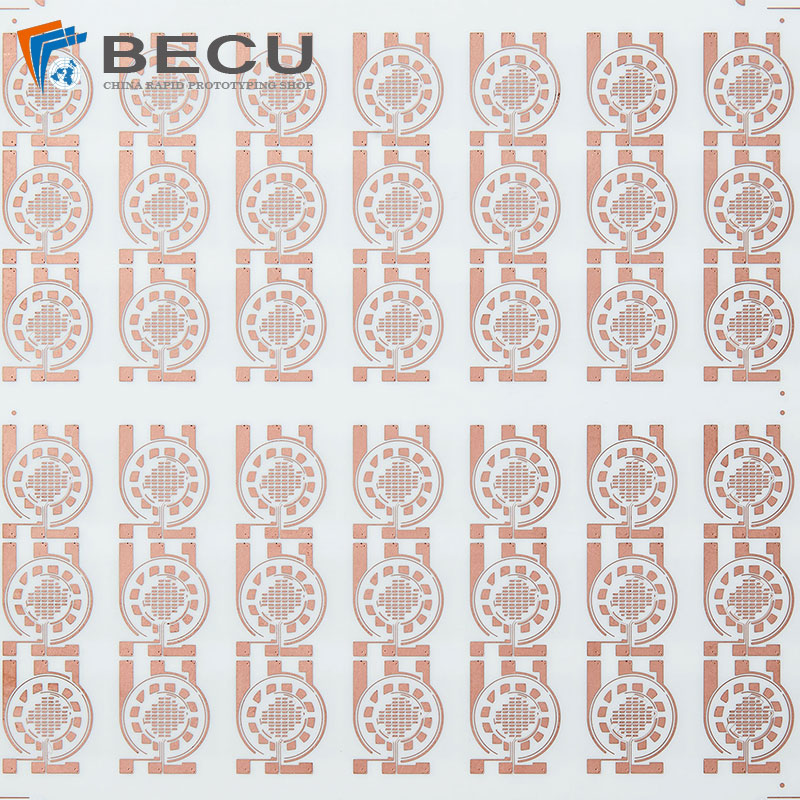

- The etching process of Be-cu has no restrictions on complex patterns and arbitrary geometric figures. No matter how complicated the hole shape or pattern is, it can be formed in one process without increasing the production cost.

- Be-cu chemical etching is a double-sided simultaneous processing technology. The surface of the product (front and back) is smooth, no bumps, no pits, no burrs, no warping, the mesh is flat and no deformation, no need to polish , Polishing, self-care process after flattening.

- The size of etching process is fine (aperture ≥ 0.1mm, thickness 0.03-2.0mm), and the positioning is accurate (minimum precision ± 0.008) uniform.

- The production cycle is short, the response is fast, and the design is easy to modify. The Be-cu professional etching technology engineering team has a total of 17 people and has senior technicians who have been in the industry for 15+ years.

- Be-cu samples are produced quickly, and samples can be produced within 1-2 working days (determined according to product requirements).

- Be-cu etching has 16 automatic etching production lines, with high etching processing output, which can meet your production orders for batch processing and etching customized microporous mesh.

- Be-cu provides auxiliary services such as stamping, welding, oil spraying, painting, electrophoresis, electroplating, electrolysis, passivation, polishing, stretching, wire drawing, silk screen LOGO, injection molding, etc., to meet the needs of different products and realize convenient and fast — One-stop processing service.

- Be-cu has passed the factory inspections of many well-known companies such as Gree, Joyoung, Xinbao, Xiaomi, Lake and American and German customers. The quality and delivery time are stable, and the customer satisfaction and employee satisfaction are high.

Contact Be Cu Now for your Custom Metal Etching, We are your best online Etching services choice!

Specifications of Etching Alumina Multi-Layered Board

| Material Type | Aluminium/Brass/Copper/Nitinol/Stainless steel/Titanium/Ceramics |

| Size | Customized |

| Min. Hole Dia. | Dia.≥1.2xT |

| Min. Pitch | D≥1.0xT |

| Tolerance | 0.003mm |

| Material Thickness | T≥0.03mm |

| Process | Etching/Plating/Stamping/Bending/Laser cuting |

| Surface Finish | PVD/Coating/Painting |

| Inspection | IPQC/AQL |

| Packing | Plastic Tray or Customized |