Slit Sheet Etching

- Material: Aluminum alloy

- Thickness: 0.5/0.6/0.7 mm

- Project Offer:Within 3 hours

- Process: Precision Etching

- Custom Cycle:Involving Mold Opening, – monthly sample delivery

- Production Capacity:5000-10000PCS/day

- Application: Semiconductor Packaging

- Add Process:Stamping, Self-Owned Hardware Mold Room, Electroplating, Electrophoresis, PVD Vacuum Plating

- Type: Aluminum Etching

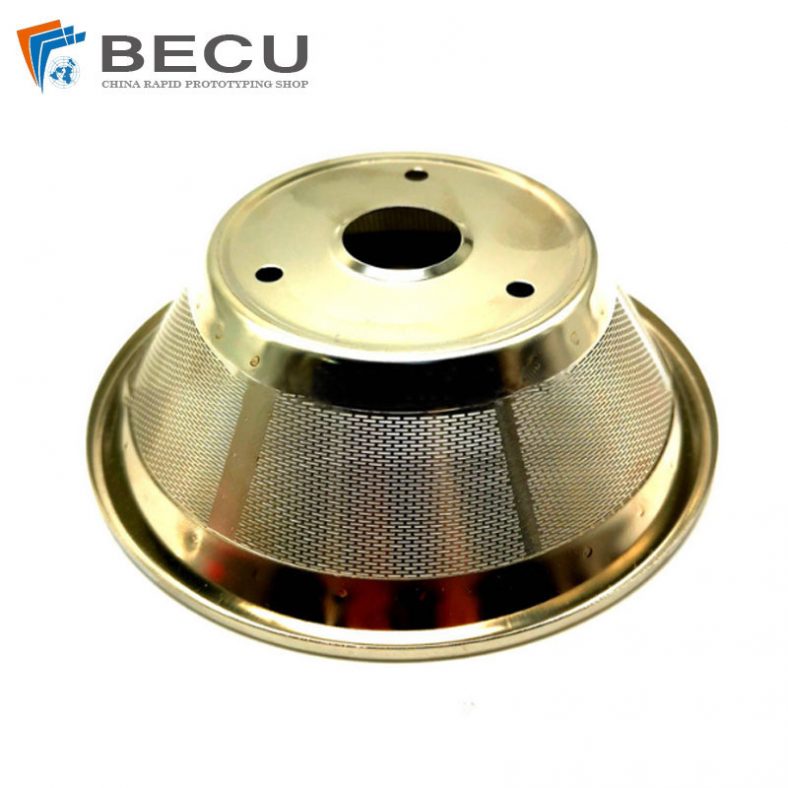

High-Quality Aluminum 6061 Slit Sheet Etching

Slit plates have a wide range of applications, and their names vary across different industries. Commonly, slit plates are used in high-end equipment such as spectrometers and colorimeters, mainly in scientific research, optical instruments, and other fields. In spectrometers, slit plates capture light information, which is then developed on photographic film or displayed and analyzed using computer-automated instruments. These devices are used in real-world applications such as air pollution, water pollution, food hygiene, and metal industry inspections, where the slit forms the optical point in the spectrometer’s imaging system under incident light.

Currently, the primary manufacturing method for slit plates is etching. The slits and thickness of slit plates are relatively thin, making traditional processing methods inadequate. Etching can achieve slit plate thicknesses between 0.01 mm and 2 mm, with common specifications being 0.03 mm and 0.05 mm.

The main characteristics of slit plate etching are as follows:

- Low-Cost Design Flexibility: Using metal photolithography to create patterns allows for arbitrary design changes at relatively low costs.

- High Precision: Etching can achieve precision up to ±0.0075 mm, meeting various product requirements.

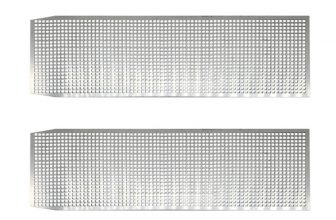

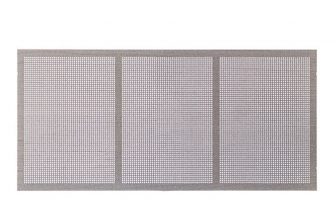

- Complex Shapes: Etching can produce slit plates with complex shapes, ensuring that the density of the slits remains consistent without deformation or breakage.

- Burr-Free Finish: Etched slit plates are burr-free, do not alter the material properties, and do not affect the functionality of the product.

Metal etching is photochemical etching. It is a process of surface treatment of metal materials, degreasing and polishing the surface, exposing and developing after covering with photosensitive ink, and then entering the etching process stage after cooling. The dissolved area is decomposed by high-concentration strong acid of iron oxide to form convex points or hollowing.

Now let’s take you into the slit sheet etching process and how to understand the etching process in the actual operation workflow.

- CAD drawing design: The thickness range that the etching machine can accept is between 0.01MM-2MM, and the largest size is 500*1500MM. If it exceeds the range, it cannot be placed on the etching machine assembly line platform and will cause the machine to jam. CAD drawings are professional engineering drawings, and professional personnel can measure parameters.

- Preparation of raw materials: Cut metal materials of corresponding sizes through automatic cutting machines according to the requirements of the drawings.

- Pre-treatment stage: Degreasing, impurity removal, cleaning and other processes are carried out on the metal materials to ensure the integrity of the materials to avoid abnormal products.

- Lamination (film lamination) stage: Enter the roller coating stage, cover the metal surface with photosensitive ink and dry it, and the constant temperature in the room is relatively high.

- Exposure stage: Attach the prepared metal film to the metal layer and use the exposure machine for exposure. Simply put, the pattern of the metal film is exposed to the metal material by the exposure machine, so as to form a metal plate with a pattern.

- Development stage: After the pattern is exposed, it is developed by the developer to make the pattern appear on the metal plate. If there are defects, the ink can be filled manually. Due to the high temperature in the development stage, the plate is relatively soft.

- Drying stage: Based on the above process, the plate is relatively soft. Direct etching is easy to cause deformation. Therefore, it needs to be cooled and dried to form a hard plate again.

- Etching process: The chemical composition of the etching solution is ferric chloride, which is fused with water to produce a high-concentration strong acid solution. When the part with photosensitive ink forms a protective layer, it will not cause dissolution, and the unprotected part exposed to the outside will produce a chemical reaction after encountering the strong acid and dissolve. Etching processing has high requirements for speed and time, so different products need to be made into the first piece to debug the machine parameters, and the finished products are tested to finally form the required products, and then the parameter values are set to fixed values, so as to achieve comprehensive mass production, similar to the way of replicating.

- Peeling (peeling operation): After the etching is completed, the photosensitive ink layer of the protective part still exists, so it is necessary to enter the next process again, that is, the peeling operation. The photosensitive ink layer is peeled off by acid, alkali, water, etc. to form a complete pattern product.

- Inspection packaging and delivery: The finished products are disassembled and packaged, and the parameter values are evaluated by the two-dimensional detection instrument to form a professional product production report, and then packaged and delivered to the customer.

Through the above description, do you clearly understand the process of slit sheet etching? The overall process of metal etching processing can fully understand that it must go through the strict requirements of ten processes to make products that satisfy customers.

Why Choose Our Aluminum 6061 Slit Sheet Etching Service?

- Etching processing technology is adopted, with high precision, up to ±0.008mm (different thickness of different materials). 15 years of professional precision etching processing factory, the quality is trustworthy.

- The etching process of Be-cu has no restrictions on complex patterns and arbitrary geometric figures. No matter how complicated the hole shape or pattern is, it can be formed in one process without increasing the production cost.

- Be-cu chemical etching is a double-sided simultaneous processing technology. The surface of the product (front and back) is smooth, no bumps, no pits, no burrs, no warping, the mesh is flat and no deformation, no need to polish , Polishing, self-care process after flattening.

- The size of etching process is fine (aperture ≥ 0.1mm, thickness 0.03-2.0mm), and the positioning is accurate (minimum precision ± 0.008) uniform.

- The production cycle is short, the response is fast, and the design is easy to modify. The Be-cu professional etching technology engineering team has a total of 17 people and has senior technicians who have been in the industry for 15+ years.

- Be-cu samples are produced quickly, and samples can be produced within 1-2 working days (determined according to product requirements).

- Be-cu etching has 16 automatic etching production lines, with high etching processing output, which can meet your production orders for batch processing and etching customized microporous mesh.

- Be-cu provides auxiliary services such as stamping, welding, oil spraying, painting, electrophoresis, electroplating, electrolysis, passivation, polishing, stretching, wire drawing, silk screen LOGO, injection molding, etc., to meet the needs of different products and realize convenient and fast — One-stop processing service.

- Be-cu has passed the factory inspections of many well-known companies such as Gree, Joyoung, Xinbao, Xiaomi, Lake and American and German customers. The quality and delivery time are stable, and the customer satisfaction and employee satisfaction are high.

Contact Be Cu Now for your Custom Metal Etching, We are your best online Etching services choice!

Specifications of Aluminum 6061 Slit Sheet Etching

| Material Type | Aluminium/Brass/Copper/Nitinol/Stainless steel/Titanium/Kovar |

| Size | Customized |

| Min. Hole Dia. | Dia.≥1.2xT |

| Min. Pitch | D≥1.0xT |

| Tolerance | 0.003mm |

| Material Thickness | T≥0.03mm |

| Process | Etching/Plating/Stamping/Bending/Laser cuting |

| Surface Finish | PVD/Coating/Painting |

| Inspection | IPQC/AQL |

| Packing | Plastic Tray or Customized |