Homepage » Metal Etching »

Precision Etching For Aluminum – Aluminum Etching

Aluminum etching is one of the most prevalent manufacturing techniques due to its ability to produce complex yet lightweight parts quickly and cost-effectively. especally 6061 aluminum, because of is excellentstrength-oweightratio low cos, recyolability and machinabilfty.

Aluminum etching is a chemical process used to selectively remove material from the surface of aluminum, typically to create intricate patterns, designs, or markings on the metal.

Aluminum etching is a subtractive manufacturing method, meaning it removes material from the aluminum rather than adding it.This process is highly efficient and can produce large quantities of parts with consistent quality.

BE-CU ETCH offers precision etching with multiple aluminum alloys.

Since aluminum is a lightweight, durable, corrosion-resistant, and versatile material, it makes an ideal choice for a wide range of applications,This process is commonly used in industries such as electronics, aerospace, and automotive, as well as for artistic and decorative purposes.

Our Aluminum Etching Service

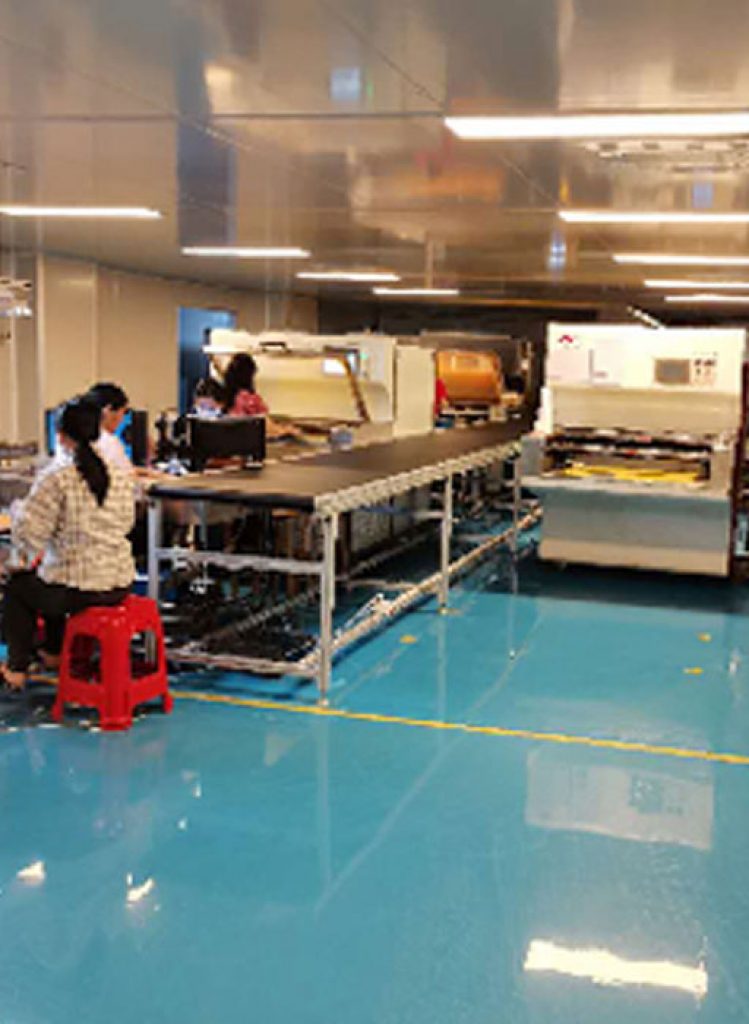

BE-CU ETCH have been providing precision etching solutions to our customers since 1995. We are experienced in manufacturing complex ALUMINUM ETCH parts at tight tolerances, and we frequently work with customers in the aerospace, defense, and medical industries. Our facilities are ISO 9001:2015 certified and are equipped with state-of-the-art etch machinery. We are dedicated to continuously improving, providing our customers with industry leading aluminum etching services at competitive prices.

At BE-CU ETCH, we utilize FIVE professional etching production line giving you the flexibility and capability to receive a finished etch part in-house. By partnering with our Sales/Engineering team, we can-inhouse etching shop jobs quickly and economically, reducing cycle times and passing those savings to you. Our inspection capabilities allow us to reduce the number of setups to give you a lower cost par and quicker delivery.

Aluminum alloys are low in density but high in strength. Our CNC machines can manufacture unique and quality aluminum prototypes. To learn more about our capabilities or to work with us on your next CNC machining project, contact us or request a quote today.

Our Etching Capabilities

- Etching of many grades of aluminum, including 6061,6063,5052 and more

- Combining Stamping, Laser Cutting,CNC machining and photochemical etching on sheets up to 2mm thick

- Etching of up to 0.025″ thick sheets as large as 22×12 inches

- Tolerances of ±.0005″ in many applications

How To Etch Aluminum

Automated-Coating

Automatic-Baking-Line

Automatic-Shearing

Coating-For-Etching-Parts

Deinking

Etching

Exposure

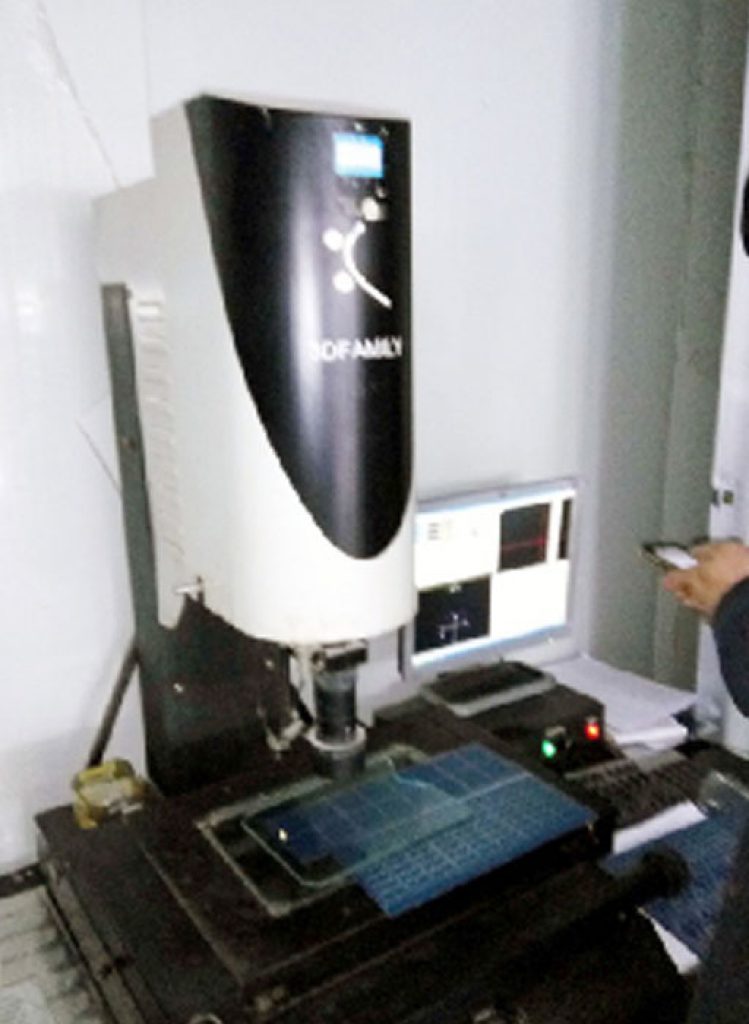

Inspection-For-Etching

Metal Grades For Aluminum Etching

Aluminum etching typically involves using chemicals to remove material from an aluminum surface to create patterns, designs, or text. The choice of the metal grade or alloy for aluminum etching depends on the specific requirements of your project. Here are some common aluminum grades and alloys used in etching:

1100 Aluminum

3003 Aluminum

5052 Aluminum

6061 Aluminum

7075 Aluminum

Anodized Aluminum

The choice of aluminum grade depends on factors such as the complexity of your etching design, desired durability, and the specific etching process you plan to use. Additionally, some aluminum alloys may require special etching solutions or techniques to achieve the desired results. Always test your chosen aluminum grade with your etching process to ensure it meets your requirements.

Components That Are Produced By Etching Aluminum

The popularity of Aluminum makes it a desirable metal for use in fabrication because it is easy to manufacture and has favorable properties for many industrial products.With the photo etching process, the metal is etched evenly without any structural deformations from the hard tooling used in stamping and punching.Since there isn’t a heat point of contact like laser cutting, the parts’ metal properties remain unchanged and free from thermal deformations.Get inspired by our custom etching part projects and contact us to Get Instant Quote for rapid prototype or Aluminum etching parts start from 1pcs.

-

Aluminum Alloy 7075 Etched Microphone Grille

-

Aluminum Etching Car Audio Speaker Mesh

-

Aluminum Alloy 6061 Etched Bookmark

-

Etched Aluminum 7075 Bluetooth Headset Diaphragm

-

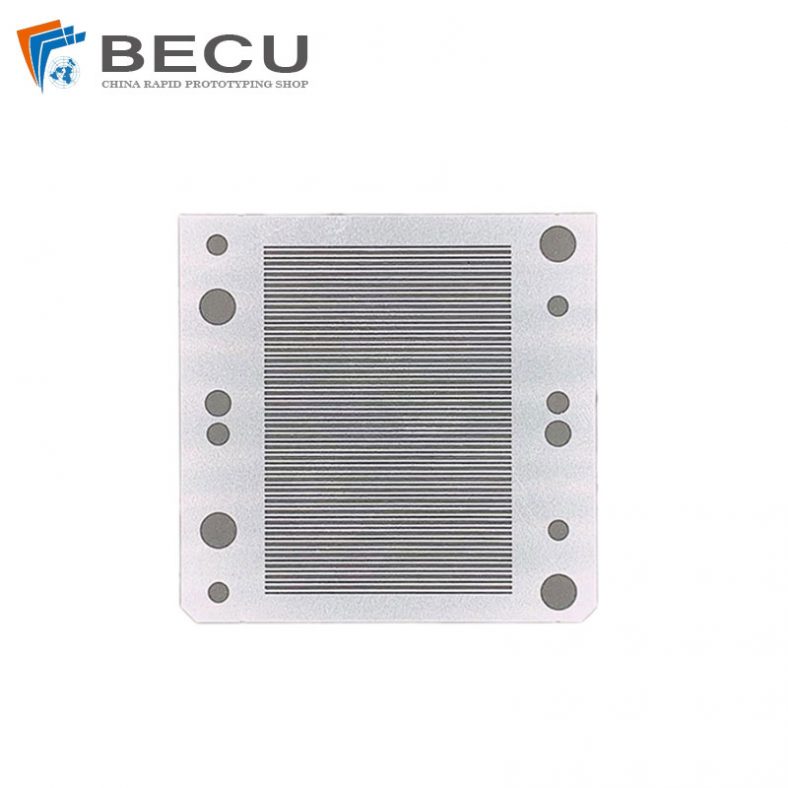

Aluminum 6061 Slit Sheet and Plates Etching

-

Precision Etching Aluminum 6061 Metal Name Sign and Number Plate

-

Precision Etched Aluminum Alloy Buttons

-

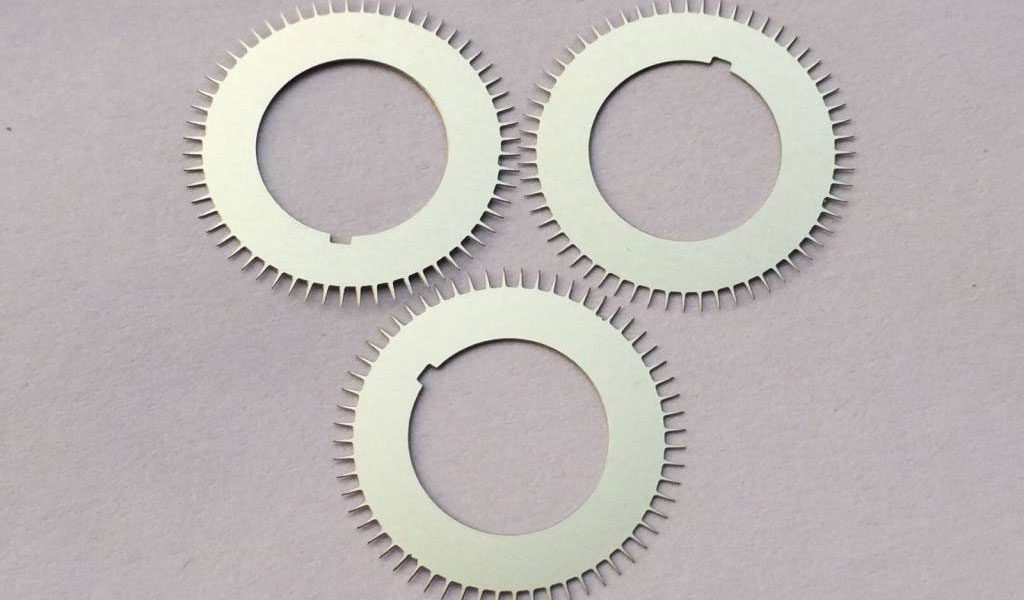

Aluminum Etching Position Code Disc

Metal Etching Certification,Equipment List and Quality

We are committed to enlisting the full support of all employees to continuously improve our processes and enhance quality, thereby fulfilling our customer's needs with defect free products and services, on time and every time

- ISO 9001:2015 certified

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process FMEA

- Fully compliant with the exacting requirements of our customers

- ITAR registered

- NIST cybersecurity standard compliant

- Proprietary Patented quality systems

- Skilled in KanBan and other customer driven quality and inventory management systems

Metal Etching Material

BE-CU is experienced in precision etching various metals, allowing customers the freedom to specify components in hundreds of different materials.

The Surface Treatment Of Metal Etching Parts

Do you want your etching parts to be more corrosion-resistant or get a specific look? Metal finishing service is a essential choice to achieve your design perfectly. BE-CU – metal-etch.com is an accomplished finished parts manufacturer, our workers and craftsman are capable to provide precision metal etching services and a wide range of finishing services including aluminum anodizing, painting, passivation, electroplating, powder coating, polishing, black oxide, conversion coating, abrasive blasting, etc. We offers several common surface finishes to help improve functionality and aesthetics.

- Anodizing (Anodized)

- Passivation

- Plating (Electroplating)

- Painting

- Black Oxide (Hot Blackening)

- Polishing

- Powder Coating

- Heat Treatment

- Satin Finish

- Abrasive blasting (Sandblasting)

- Conversion coating

- Tungsten carbide coating

After browsing a list of metal finishing services, select a process based on essential considerations, like production time, cost-effectiveness, part tolerance, durability and applications. High-tolerance metal etching parts are not recommended to apply secondary metal surface finish, because the treatment may change the sizes of the finished part through removing or adding a small amount of materials.

Other requirements or custom designs, welcome to contact us for a free quote fast!