Homepage » Metal Etching »

Art Etching – Metal Etching for Artwork

Metal etching, a process utilized for creating intricate designs and patterns on metal surfaces, has gained significant traction in the art industries. This technique not only provides artists with a unique medium to express their creativity but also facilitates the production of fine art, jewelry, and functional pieces. The practice of metal etching is rooted in historical methods, evolving into a sophisticated art form that combines traditional craftsmanship with modern technology.

The origins of metal etching can be traced back to the Renaissance period in Europe. Artists began experimenting with the technique, employing acid to create detailed designs on metal plates. The most notable method during this time was the use of copper plates, where artists would draw their designs on the surface using a sharp tool, known as a burin.

The uncovered areas were then subjected to an acid bath, which would eat away at the metal, creating a permanent impression of the design. This process allowed for the reproduction of artworks through printmaking, giving rise to a new avenue for artistic expression.

Throughout the centuries, metal etching techniques diversified, with artists exploring different materials, including zinc and aluminum. The introduction of modern chemical etching processes in the 20th century revolutionized the art form. These advancements allowed for greater precision and complexity in designs, broadening the scope of what could be achieved through metal etching.

Our Art Etching Service

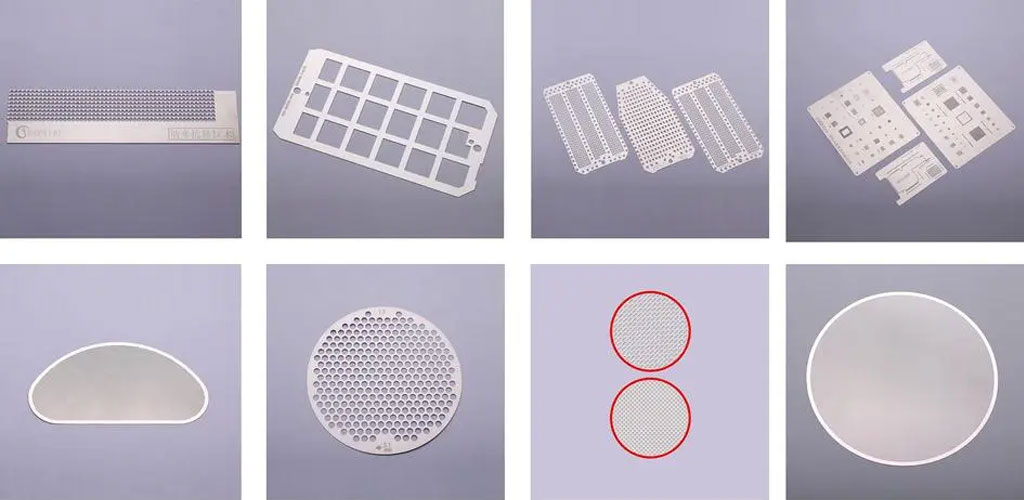

If you need art parts etched we are one of the most capable and affordable sources specializing in manufacturing custom etched parts on advanced photo etching machines with cnc precision. Through our Photo Chemical Etching process, the smallest and most complex designs are made possible such as electrical spring contacts, contact membranes, busbars, antennae and micro antennae, spring fingered contacts, heating elements and battery terminal as well as many other bespoke components to your own designs.

We can machine to print and accept the most common file formats including: .dwg .dxf .iges .step .sat as well as .pdf files. If you don’t see your file format here let us know. Please send us files to: [email protected] We can accept both small and large run jobs of custom Art etching parts.

Our Etching Capabilities

- Etching of many grades of metal and more

- Combining Stamping, Laser Cutting,CNC machining and photochemical etching on sheets up to 2mm thick

- Etching of up to 0.025″ thick sheets as large as 22×12 inches

- Tolerances of ±.0005″ in many applications

How To Etch Art Parts

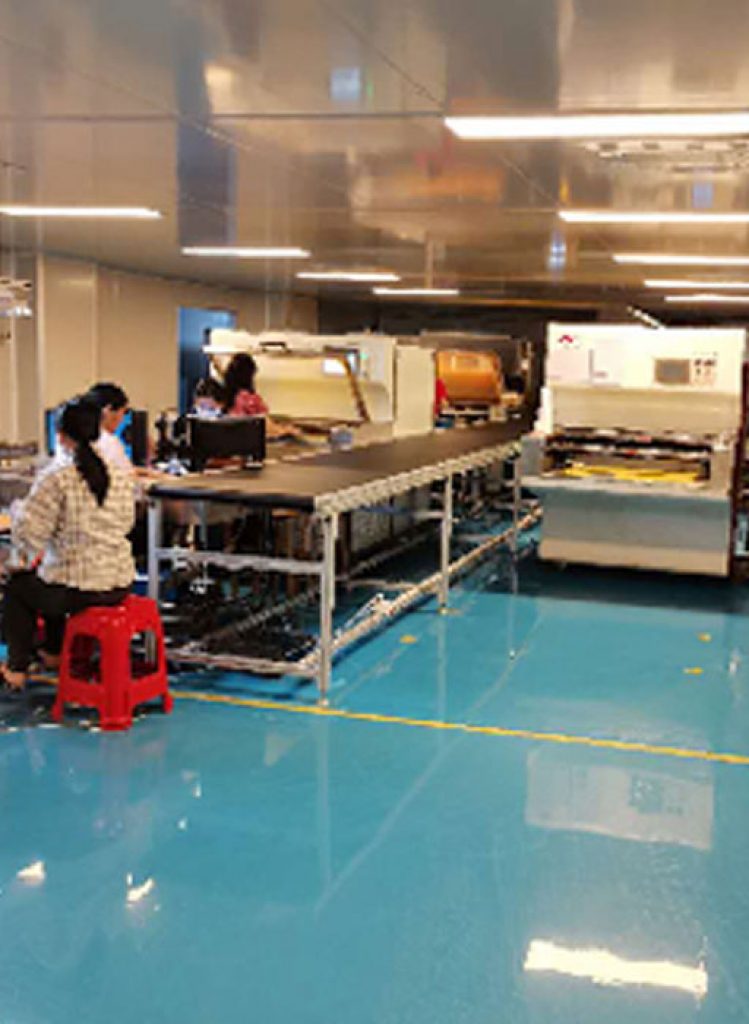

Automated-Coating

Automatic-Baking-Line

Automatic-Shearing

Coating-For-Etching-Parts

Deinking

Etching

Exposure

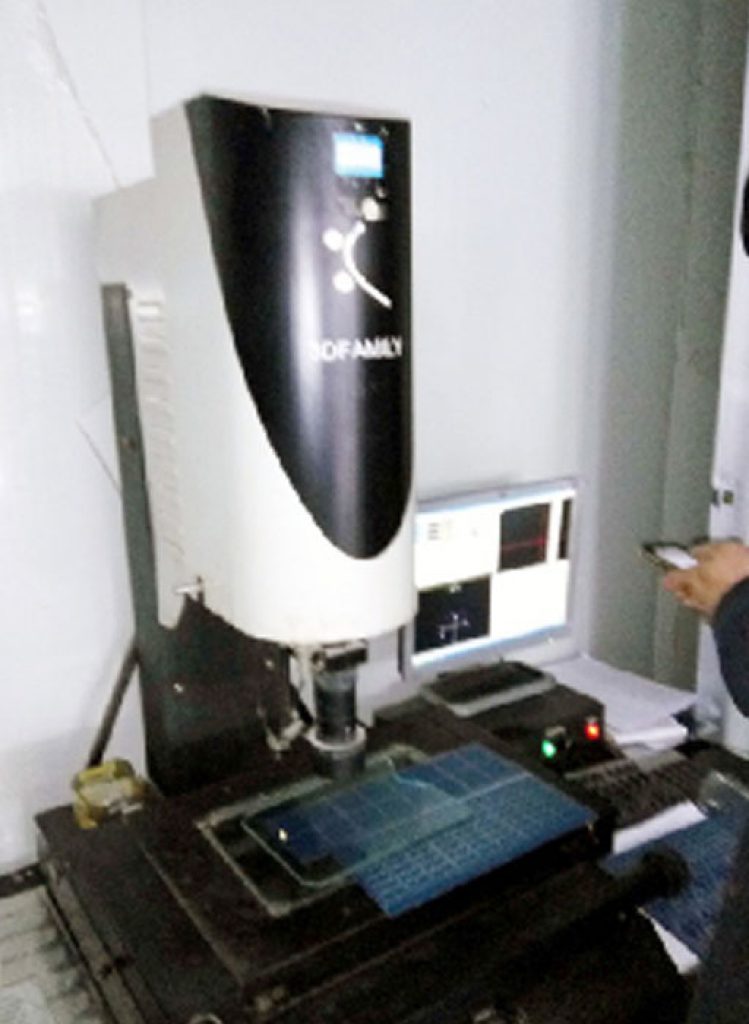

Inspection-For-Etching

Types of Art Etching

Metal etching can be categorized into several techniques, each with its distinct methods and applications. Among these, traditional etching, photochemical etching, and laser etching are the most prominent.

Traditional Etching For Art

Traditional etching involves several steps, beginning with the preparation of the metal plate. Artists typically use copper or zinc plates, which are cleaned and polished to achieve a smooth surface. A coating of wax or resin is then applied, providing a barrier to protect the metal from acid.

Once the plate is prepared, the artist uses a needle or burin to draw the desired design onto the wax surface, exposing the metal underneath. The plate is then submerged in a diluted acid bath, which etches away the exposed metal. The depth of the etch can be controlled by the duration of exposure to the acid. After the etching process is complete, the plate is cleaned, and ink is applied to the etched areas. The ink is then wiped off the surface, leaving the ink only in the etched grooves. Finally, the plate is pressed onto paper using a printing press, producing a detailed print of the original design.

Photochemical Etching For Art

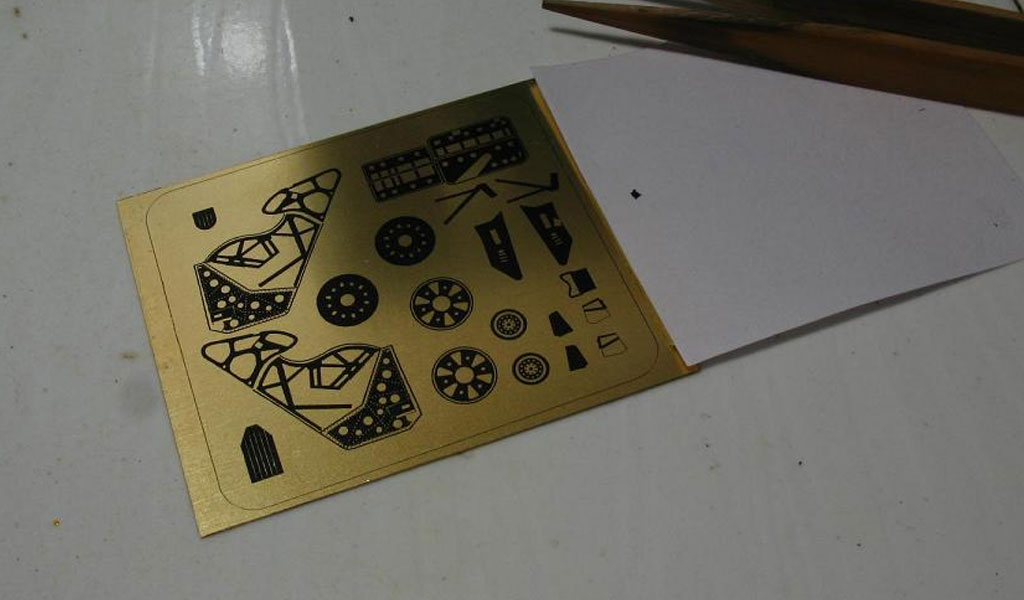

Photochemical etching, also known as photo-etching, utilizes a photographic process to create designs on metal surfaces. In this method, a photosensitive film is applied to the metal, and the desired image is transferred onto the film through exposure to ultraviolet light. The unexposed areas are then washed away, revealing the metal underneath. Following this, the exposed metal is subjected to an etching solution, which removes the metal in the exposed areas, creating a precise design.

This technique offers several advantages over traditional etching, including greater accuracy and the ability to reproduce complex images with fine details. It is particularly favored in the production of artistic prints and industrial applications, such as electronic components and decorative items.

Laser Etching For Art

Laser etching is a modern method that employs high-powered lasers to etch designs onto metal surfaces. This technique has gained popularity due to its speed, precision, and versatility. The laser beam effectively removes material from the surface of the metal, allowing for intricate designs to be created quickly and efficiently.

Laser etching can be applied to a wide variety of metals, including stainless steel, aluminum, and titanium. The process is often used in the production of custom jewelry, decorative panels, and art pieces. Additionally, laser etching can be combined with other technologies, such as 3D printing, to create unique mixed-media artworks.

Applications of Art Etching

Metal etching serves a diverse range of applications in the art industries, including fine art, jewelry design, sculpture, and functional art. Each application leverages the unique qualities of metal etching to create visually striking and tactile works.

1. Fine Art

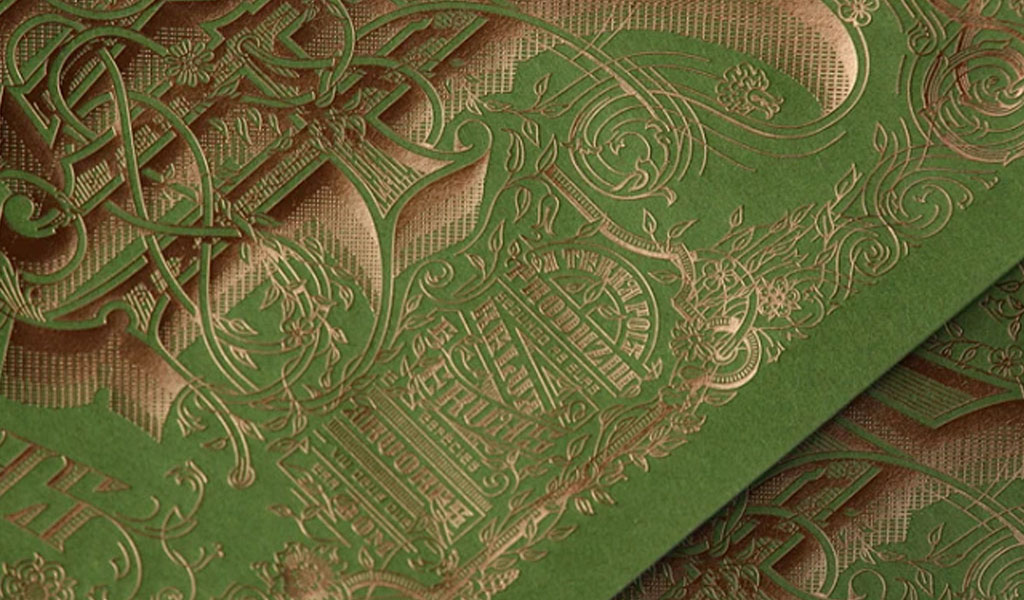

In the realm of fine art, metal etching is employed by artists to produce limited edition prints. The tactile nature of etched metal plates adds a unique dimension to the artwork, allowing for variations in texture and depth. Artists often create series of prints using the same plate, each one exhibiting slight differences, making each piece unique. This technique not only enhances the visual appeal but also adds value, as limited editions are highly sought after by collectors.

Many contemporary artists experiment with combining etching techniques with other art forms, such as painting and drawing, to create mixed-media works. This fusion of techniques enables artists to explore new creative possibilities and push the boundaries of traditional metal etching.

2. Jewelry Design

Metal etching has also found a prominent place in the world of jewelry design. Artisans use etching techniques to create intricate patterns and designs on metal components, such as pendants, earrings, and bracelets. This allows for the production of unique, custom pieces that stand out in the marketplace.

Jewelry designers often combine etching with other techniques, such as soldering and stone setting, to create multidimensional pieces. The ability to etch fine details onto metal enhances the overall aesthetic, making each piece a testament to the artisan’s skill and creativity.

3. Sculpture

Metal etching can be effectively utilized in sculptural works, where artists employ the technique to add detail and texture to their sculptures. The etched patterns can create visual interest and depth, enhancing the viewer’s experience. Artists often use various metals, including bronze and stainless steel, to achieve different effects and finishes.

Sculptors may also incorporate etching into larger installations, combining it with other materials and techniques to create immersive environments. The interplay of light and shadow on the etched surfaces adds an additional layer of complexity to the work, inviting viewers to engage with the piece from multiple angles.

4. Functional Art

In the context of functional art, metal etching is used to create decorative yet practical items, such as tableware, lighting fixtures, and home decor. Designers employ etching techniques to produce unique patterns and motifs that elevate everyday objects into works of art. This approach not only enhances the aesthetic appeal but also adds a personal touch to functional items.

Components That Are Produced By Etching Art Parts

The popularity of Art makes it a desirable metal for use in fabrication because it is easy to manufacture and has favorable properties for many industrial products.With the photo etching process, the metal is etched evenly without any structural deformations from the hard tooling used in stamping and punching.Since there isn’t a heat point of contact like laser cutting, the parts’ metal properties remain unchanged and free from thermal deformations.Get inspired by our custom etching part projects and contact us to Get Instant Quote for rapid prototype or Art etching parts start from 1pcs.

-

Copperplate Engravings Of World Famous Works

-

Artistic Etched Copper Shielding Electronics Playing Cards with Patterns

-

Zinc Alloy Nameplate Etching For Bags Logo/Signs

-

3D Etching Brass H62 Incense Burner

-

Brass 360 Hollow Etched Hangtag

-

Precision Etching H59 Butterfly Pendant Jewelry

-

Laser Etching H62 Brass Pendant Jewelry

-

Aluminum Alloy 6061 Etched Bookmark

Metal Etching Certification,Equipment List and Quality

We are committed to enlisting the full support of all employees to continuously improve our processes and enhance quality, thereby fulfilling our customer's needs with defect free products and services, on time and every time

- ISO 9001:2015 certified

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process FMEA

- Fully compliant with the exacting requirements of our customers

- ITAR registered

- NIST cybersecurity standard compliant

- Proprietary Patented quality systems

- Skilled in KanBan and other customer driven quality and inventory management systems

Metal Etching Material

BE-CU is experienced in precision etching various metals, allowing customers the freedom to specify components in hundreds of different materials.

The Surface Treatment Of Metal Etching Parts

Do you want your etching parts to be more corrosion-resistant or get a specific look? Metal finishing service is a essential choice to achieve your design perfectly. BE-CU – metal-etch.com is an accomplished finished parts manufacturer, our workers and craftsman are capable to provide precision metal etching services and a wide range of finishing services including aluminum anodizing, painting, passivation, electroplating, powder coating, polishing, black oxide, conversion coating, abrasive blasting, etc. We offers several common surface finishes to help improve functionality and aesthetics.

- Anodizing (Anodized)

- Passivation

- Plating (Electroplating)

- Painting

- Black Oxide (Hot Blackening)

- Polishing

- Powder Coating

- Heat Treatment

- Satin Finish

- Abrasive blasting (Sandblasting)

- Conversion coating

- Tungsten carbide coating

After browsing a list of metal finishing services, select a process based on essential considerations, like production time, cost-effectiveness, part tolerance, durability and applications. High-tolerance metal etching parts are not recommended to apply secondary metal surface finish, because the treatment may change the sizes of the finished part through removing or adding a small amount of materials.

Other requirements or custom designs, welcome to contact us for a free quote fast!