Brass labels, particularly custom-made versions, have emerged as a versatile and popular choice for various applications due to their aesthetic appeal, durability, and high degree of customization. Whether for industrial, artistic, or personal purposes, custom brass labels provide both functional and decorative solutions. They are widely used in numerous sectors, including manufacturing, architecture, interior design, and product branding. This article will explore the various aspects of custom brass labels, from their production methods to their diverse uses, materials, benefits, and challenges, providing an in-depth understanding of why they are a favored choice for creating labels, plaques, and nameplates.

The History of Brass Labels

Brass, an alloy primarily composed of copper and zinc, has been used for millennia due to its natural corrosion resistance, attractive appearance, and ease of fabrication. Historically, brass has been used for coins, jewelry, and instruments, but over time, its application expanded to include industrial uses, particularly for labels and markers. The tradition of engraving labels on brass can be traced back to ancient civilizations, where metal plates were inscribed with important information such as names, titles, and instructions.

The evolution of brass labels into custom designs began in the industrial revolution when mass production techniques, including casting, embossing, and etching, made it easier to create detailed, personalized labels. In the modern era, the rise of technology such as laser engraving and CNC machining further advanced the customization possibilities, making brass labels an attractive option for businesses and individuals seeking durable and high-quality markers.

Composition and Characteristics of Brass

Brass is an alloy made primarily of copper (Cu) and zinc (Zn), but it can also include other elements such as lead, iron, tin, aluminum, and manganese, depending on the desired properties. The specific composition of brass affects its appearance, strength, and corrosion resistance. The two most common types of brass used in custom labels are:

- Yellow Brass (CuZn37): This is the most widely used type of brass, consisting of 63% copper and 37% zinc. It is known for its bright, gold-like appearance and is highly corrosion-resistant.

- Red Brass (CuZn15): Red brass contains more copper and less zinc than yellow brass, giving it a reddish hue. It is stronger and more resistant to corrosion than yellow brass, making it suitable for applications in harsh environments.

Brass alloys are typically characterized by their excellent machinability, which allows for intricate designs to be etched, engraved, or stamped onto the surface. Additionally, brass is known for its malleability, making it easy to work with, as well as its natural resistance to tarnishing and corrosion, especially when exposed to the elements.

The Manufacturing Process of Custom Brass Labels

The creation of custom brass labels involves several steps, which can vary depending on the complexity of the design, the desired finish, and the type of label required. While traditional methods like engraving and embossing are still in use, modern technologies such as laser cutting and CNC machining have revolutionized the process. Below are some of the key methods used to produce custom brass labels:

- Engraving: Engraving involves carving or etching designs onto the surface of brass using either manual tools or computerized machines. This technique can produce both shallow and deep engravings and is ideal for fine details, logos, or text. Engraving is often used for smaller, intricate custom labels where precise control over the design is necessary.

- Stamping and Die-Cutting: In stamping, a die is used to press the design into the brass, which can either create raised or recessed patterns. Die-cutting involves cutting the brass sheet into the desired shape or design. These methods are ideal for creating large quantities of uniform labels with consistent dimensions.

- Laser Engraving: Laser engraving utilizes a focused laser beam to remove material from the surface of the brass. This method is particularly useful for creating fine, detailed engravings and is capable of producing high-resolution images, text, or logos on custom brass labels. Laser engraving is a precise and efficient process that can be used for both small and large batches.

- CNC Machining: Computer Numerical Control (CNC) machining involves the use of automated tools to carve or cut brass into the desired shape. This method is ideal for creating complex designs with high precision and can be used for both engraving and shaping brass labels. CNC machining is a highly accurate process that allows for detailed customization and consistency.

- Etching: Etching is a process that uses chemicals or acids to create designs on the surface of brass. This method can be used to produce fine lines and patterns, making it ideal for more intricate or artistic labels. Etching is typically used for decorative applications where a unique finish is required.

- Casting: Casting involves pouring molten brass into a mold to create a custom label or plaque. This process is ideal for creating three-dimensional designs or labels with intricate reliefs. The casting process is often used for larger, heavy-duty labels that require more substantial thickness or added detail.

Designing Custom Brass Labels

The design of custom brass labels is a crucial factor in determining their aesthetic and functional qualities. When creating a brass label, several considerations must be taken into account, such as the purpose of the label, the type of information to be included, the target audience, and the environment in which the label will be used.

Typography and Graphics

The choice of typography is essential for creating legible, professional-looking brass labels. Since brass is a metal surface, fine details need to be large enough to be easily read. Custom brass labels can include a wide range of typographic styles, from modern sans-serif fonts to more traditional or decorative typefaces. Additionally, graphics such as logos, symbols, or artwork can be incorporated into the design to enhance the label’s visual appeal and brand identity.

Color and Finish

While brass itself has a distinctive gold-like color, the surface of custom brass labels can be treated to achieve various finishes and effects. These finishes can range from highly polished and shiny surfaces to matte or brushed textures. Some common surface treatments for brass labels include:

- Polishing: Creates a shiny, reflective surface that emphasizes the metallic beauty of brass.

- Brushed Finish: Achieved by applying abrasive material to the surface, producing a matte finish with fine lines.

- Antique or Aged Finishes: These finishes are created by chemically aging the brass to give it a vintage or rustic appearance.

- Patina: Patina is a natural or artificial layer of oxidation that forms on the surface of brass over time. Some custom brass labels are intentionally patinated for an antique, aged look.

Shape and Size

Brass labels can be manufactured in nearly any shape, from simple rectangles to custom designs like circles, ovals, or more intricate outlines. The size of the label depends on the intended use, the amount of text or artwork to be included, and the location where the label will be applied. Customization in terms of shape and size is one of the key reasons brass labels are sought after for a wide range of uses.

Applications of Custom Brass Labels

Custom brass labels are used in a variety of industries and settings, each with its unique requirements. Below are some of the most common applications for custom brass labels:

Architectural and Interior Design

Custom brass labels are often used in architectural applications, such as door nameplates, room numbers, or property markers. Their durability makes them an excellent choice for both indoor and outdoor use. In interior design, brass labels are used on furniture, lighting fixtures, and decorative elements to add a touch of elegance and sophistication. The versatility of custom brass labels allows them to complement various design aesthetics, from modern minimalism to traditional styles.

Industrial and Manufacturing

In industrial and manufacturing settings, custom brass labels are used for equipment identification, safety warnings, and operational instructions. Brass labels are often chosen for these applications due to their resistance to corrosion, especially in harsh environments where other materials may degrade. Whether for machines, tanks, or control panels, brass labels provide a durable, long-lasting solution for labeling.

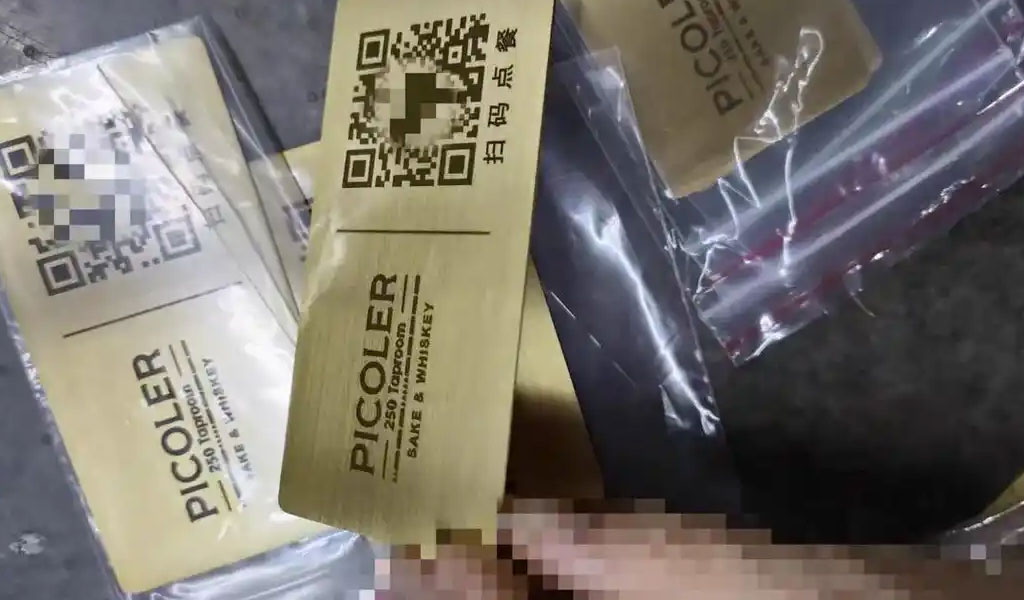

Product Branding and Packaging

Custom brass labels are an excellent choice for product branding, particularly for high-end products such as luxury items, premium equipment, and designer goods. These labels can be engraved with the company’s logo, product information, or serial numbers, providing both branding and authenticity. Brass labels can be affixed to products, packaging, or promotional materials to elevate the product’s perceived value.

Awards and Recognition

Custom brass labels are frequently used in the creation of awards, plaques, and trophies. These labels can be engraved with the recipient’s name, the award title, and other details to create a meaningful and lasting recognition. Brass’s natural lustrous finish gives these awards a prestigious, timeless quality.

Memorials and Commemorative Plaques

Brass is a popular material for memorial plaques and commemorative markers, such as gravestones or tribute plaques. Its resistance to corrosion ensures that these labels will remain intact for many years, even when exposed to the elements. Custom brass labels used in memorials are often engraved with names, dates, and inscriptions, offering a dignified way to honor the memory of individuals or events.

Benefits of Custom Brass Labels

There are several key advantages to choosing custom brass labels over other materials such as plastic, aluminum, or stainless steel:

- Durability: Brass is highly resistant to corrosion, oxidation, and tarnishing, ensuring that the labels maintain their appearance and legibility over time.

- Aesthetic Appeal: Brass has an attractive, warm, golden hue that adds a touch of elegance and sophistication to any application.

- Customization: Brass labels can be customized to meet specific size, shape, design, and finish requirements, making them ideal for a wide range of uses.

- Eco-Friendliness: Brass is a recyclable material, making custom brass labels an environmentally sustainable choice.

- High-Quality Feel: Brass labels exude a sense of quality and luxury, making them a preferred option for high-end products and services.

Challenges of Custom Brass Labels

While custom brass labels offer many advantages, there are also some challenges to consider:

- Cost: Brass can be more expensive than other materials such as plastic or aluminum, especially when customized with intricate designs or finishes.

- Weight: Brass is a heavier material than many other options, which may be a consideration for certain applications.

- Maintenance: While brass is highly durable, it can require periodic cleaning and polishing to maintain its appearance, particularly if an antique or shiny finish is desired.

Conclusion

Custom brass labels are an enduringly popular choice for labeling, branding, and decorative purposes due to their unique combination of aesthetic appeal, durability, and versatility. From industrial applications to luxury products and commemorative plaques, brass labels offer a long-lasting, high-quality solution. Their rich history, coupled with modern manufacturing techniques, ensures that they remain relevant across a wide range of industries. Whether you are designing a new product, marking an important location, or recognizing achievement, custom brass labels provide a sophisticated and enduring choice.