Glass etching is a fascinating and intricate process that transforms ordinary glass surfaces into artistic masterpieces. Through various techniques, artists and craftsmen can create stunning patterns, designs, and textures on glass, adding a unique charm and value to everyday items. This article explores the history, techniques, applications, and cultural significance of glass etching, providing a comprehensive understanding of this beautiful art form.

History of Glass Etching

The origins of glass etching can be traced back to ancient civilizations, where craftsmen developed rudimentary methods to decorate glass.

In ancient Egypt, Rome, and Mesopotamia, artisans used simple tools and abrasive materials to carve designs into glass surfaces. These early techniques laid the foundation for more sophisticated methods developed in later centuries.

Renaissance and the Evolution of Techniques

The Renaissance period marked a significant advancement in glass etching techniques. During this time, European craftsmen began experimenting with acid etching, a process that involves using acid to create designs on glass. This method allowed for more intricate and delicate patterns, leading to the production of beautifully decorated glassware.

Modern Developments

In the 19th and 20th centuries, glass etching experienced further evolution with the introduction of new technologies and materials. The development of sandblasting, a technique that uses high-pressure air mixed with abrasive particles to etch glass, revolutionized the field. This method allowed for greater precision and control, making it possible to create highly detailed and complex designs.

Techniques of Glass Etching

Acid Etching

Acid etching is one of the oldest and most traditional methods of glass etching. It involves applying an acid-resistant material, such as wax or a special resist, to the glass surface. The exposed areas are then treated with acid, which corrodes the glass and creates the desired pattern.

- Materials and Equipment: The primary materials used in acid etching include hydrofluoric acid, resist materials, and protective gear. Proper ventilation and safety measures are crucial due to the hazardous nature of the chemicals involved.

- Process: The process begins by cleaning the glass thoroughly to ensure proper adhesion of the resist material. The design is then applied using various techniques, such as stenciling or freehand drawing. Once the resist is in place, the glass is immersed in or coated with acid. After the desired etching depth is achieved, the resist is removed, revealing the etched design.

Sandblasting

Sandblasting is a versatile and widely used method for etching glass. It involves directing a high-pressure stream of abrasive particles, such as sand or aluminum oxide, onto the glass surface. This technique allows for greater control over the depth and texture of the etch.

- Materials and Equipment: Sandblasting requires a sandblasting machine, abrasive materials, stencils, and protective gear. The choice of abrasive material and nozzle size can significantly affect the final result.

- Process: The process begins by covering the areas of the glass that should remain unetched with stencils or resist materials. The glass is then placed in a sandblasting cabinet, and the abrasive stream is directed onto the exposed areas. By adjusting the pressure and duration, the artist can achieve different textures and depths.

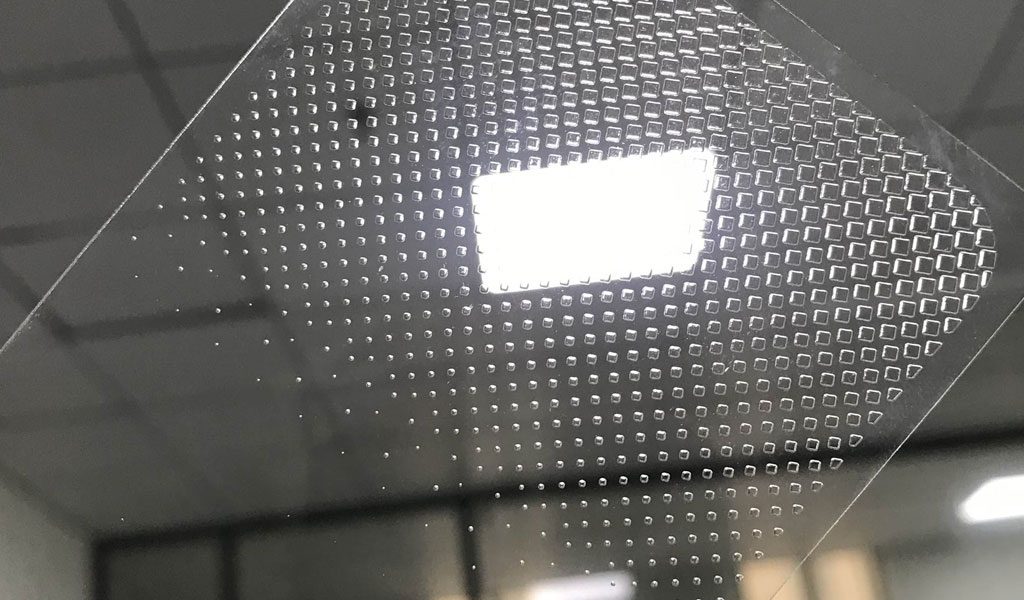

Laser Etching

Laser etching is a modern technique that uses focused laser beams to etch designs onto glass surfaces. This method offers unparalleled precision and the ability to create highly detailed and intricate patterns.

- Materials and Equipment: Laser etching requires a laser engraving machine, computer software for design creation, and protective gear. Different types of lasers, such as CO2 lasers, are used depending on the glass type and desired effect.

- Process: The process begins with designing the pattern using specialized software. The design is then transferred to the laser engraving machine, which directs the laser beam onto the glass surface. The laser beam vaporizes the glass, creating the etched design with exceptional precision.

Applications of Glass Etching

Decorative Art

Glass etching is widely used in decorative art to create unique and aesthetically pleasing pieces. Artists use various etching techniques to embellish glassware, mirrors, windows, and other glass objects. These decorative items often feature intricate patterns, floral designs, geometric shapes, and personalized motifs.

Architectural Applications

In architecture, glass etching is used to enhance the visual appeal and functionality of buildings. Etched glass panels, doors, and windows can add elegance and privacy to residential and commercial spaces. The use of frosted and etched glass in partitions and balustrades also contributes to modern and sophisticated interior designs.

Functional Items

Beyond decorative and architectural uses, glass etching is applied to functional items to add a touch of personalization and uniqueness. Common examples include etched glassware, such as wine glasses, vases, and bowls, which often feature monograms, logos, or custom designs. Etched mirrors and glass furniture are also popular in interior design.

Cultural Significance

Symbolism and Tradition

Glass etching holds cultural significance in many societies, often symbolizing craftsmanship, tradition, and artistic expression. In various cultures, etched glass objects are used in ceremonies, celebrations, and religious rituals, representing beauty and purity.

Contemporary Art

In contemporary art, glass etching continues to be a medium for creative expression. Modern artists push the boundaries of traditional techniques, experimenting with new materials, technologies, and concepts. Etched glass installations and sculptures are frequently featured in galleries and exhibitions worldwide.

Safety Considerations

Handling Chemicals

Working with chemicals in acid etching requires strict safety measures. Hydrofluoric acid, in particular, is highly dangerous and can cause severe injuries. Proper protective gear, including gloves, goggles, and lab coats, is essential. Additionally, working in a well-ventilated area and following safety protocols is crucial to prevent accidents.

Sandblasting Safety

Sandblasting also involves risks due to the high-pressure abrasive particles. Protective equipment, such as gloves, masks, and eye protection, is necessary to prevent injuries and inhalation of dust. Ensuring proper ventilation and using a sandblasting cabinet can minimize exposure to harmful particles.

Laser Safety

Laser etching requires caution due to the high-intensity laser beams used. Protective eyewear and adherence to safety guidelines are essential to prevent eye injuries. Proper training in operating laser engraving machines is also important to ensure safe and effective use.

Future Trends and Innovations

Technological Advancements

The field of glass etching continues to evolve with advancements in technology. Innovations such as computer-aided design (CAD) software, automated etching machines, and eco-friendly materials are transforming the industry. These developments enable artists and craftsmen to create more complex and precise designs while minimizing environmental impact.

Sustainable Practices

As environmental awareness grows, sustainable practices in glass etching are gaining importance. Eco-friendly resist materials, safer etching chemicals, and recycling initiatives are being adopted to reduce the ecological footprint of glass etching processes. This shift towards sustainability ensures that the art form can thrive while preserving the environment.

Conclusion

Glass etching is a timeless and versatile art form that adds a unique charm to glass surfaces. From ancient techniques to modern innovations, the evolution of glass etching reflects the creativity and ingenuity of artists and craftsmen. Whether used in decorative art, architecture, or functional items, etched glass continues to captivate and inspire, making it a cherished and enduring craft.