Kovar alloys belong to a class of iron-nickel-cobalt alloys designed to have a low coefficient of thermal expansion (CTE) matching that of borosilicate glass. This characteristic makes them particularly valuable in applications where a tight mechanical and electrical connection between metal and glass is required, such as in electronic devices, vacuum tubes, and hermetic seals.Kovar alloys, known for their unique blend of thermal expansion properties and durability, are essential materials in modern engineering and manufacturing. This article delves into the common grades of Kovar alloys, detailing their compositions, properties, and applications across various industries.

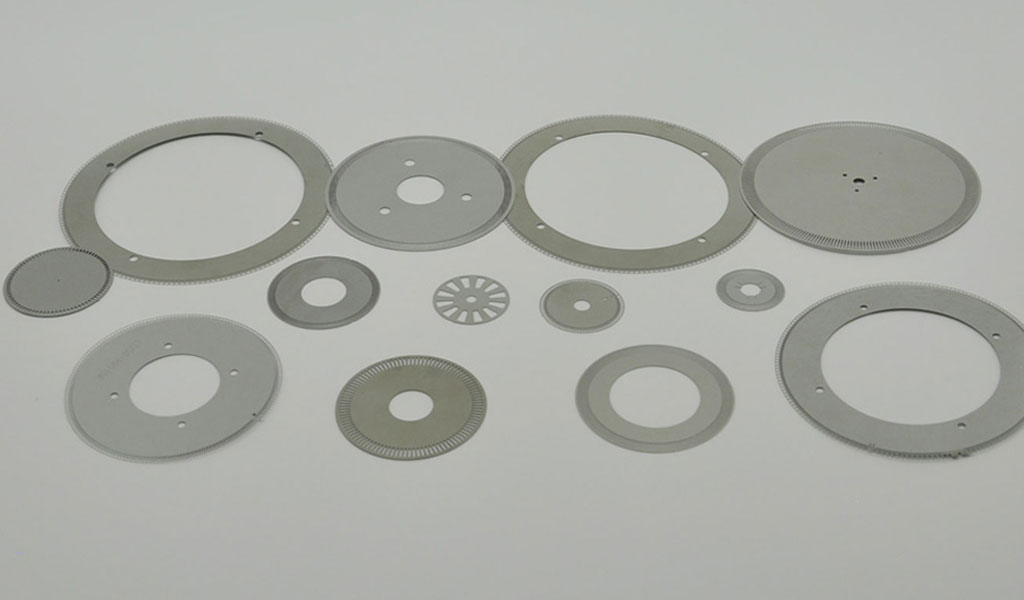

Kovar alloy is an iron-nickel-cobalt alloy known for its excellent thermal expansion properties and good weldability,and used for kovar etching. Due to its low thermal expansion coefficient, weldability, dimensional stability, and long lifespan, Kovar alloy finds widespread applications in electronic devices, aerospace, optical devices, and vacuum technology. Below are descriptions of some commonly used grades of Kovar alloy and their applications:

ASTM F15

ASTM F15 is the standard designation by the American Society for Testing and Materials (ASTM) for Kovar alloy. It is an iron-nickel-cobalt alloy primarily composed of iron (Fe), nickel (Ni), and cobalt (Co), with small amounts of silicon (Si) and manganese (Mn). ASTM F15 Kovar alloy has a thermal expansion coefficient closely matched to that of borosilicate glass, making it commonly used for seals in electronic devices and vacuum technology.The composition typically includes:

- Nickel (Ni): Approximately 29%.

- Cobalt (Co): Approximately 17%.

- Balance Iron (Fe): Remaining percentage with trace elements such as manganese and silicon.

Properties

- Coefficient of Thermal Expansion: Approximately 4.6 x 10^-6 K^-1 (20-400°C).

- Density: Around 8.36 g/cm³.

- Electrical Resistivity: Typically 49 μΩ·cm.

Applications

- Electronic Packages: Hermetic seals for microelectronic components.

- Glass-to-Metal Seals: Reliable bonding between glass and metal parts in electronics and telecommunications.

UNS K94610

UNS K94610 is the first standard designation for Kovar alloy set by ASTM. Its chemical composition and properties are similar to ASTM F15 Kovar alloy. UNS K94610 Kovar alloy, like ASTM F15, is an iron-nickel-cobalt alloy used not only in electronic devices and vacuum technology but also extensively in aerospace for sensors, connectors, and pressure-bearing structures.The composition includes:

- Nickel (Ni): Approximately 29%.

- Cobalt (Co): Approximately 17%.

- Manganese (Mn): Adds to the strength and ductility.

- Silicon (Si): Enhances oxidation resistance.

Properties:

- Coefficient of Thermal Expansion: Similar to ASTM F15, around 4.6 x 10^-6 K^-1.

- High Strength: Improved mechanical properties for rigorous applications.

- Corrosion Resistance: Enhanced resistance to environmental degradation.

Applications:

- Aerospace Components: Critical parts in satellites and space vehicles.

- Medical Devices: Implantable sensors and electronic components requiring biocompatibility.

Nilo-K

Nilo-K is a trademarked name developed by the German alloy manufacturer VDM Metals for an iron-nickel-cobalt alloy, essentially identical to ASTM F15 Kovar alloy. Nilo-K alloy shares similar thermal expansion coefficient and weldability characteristics with Kovar alloy, commonly used for seals and components in electronic devices, optical equipment, and vacuum technology.The composition generally includes:

- Nickel (Ni): Approximately 29%.

- Cobalt (Co): Approximately 18%.

- Iron (Fe): Balance, with controlled levels of other elements.

Properties:

- Coefficient of Thermal Expansion: Slightly adjusted to suit particular glass types or manufacturing processes.

- Machinability: Improved ease of machining for complex components.

- Dimensional Stability: Maintains precise dimensions under varying temperatures.

Applications:

- Telecommunication Devices: Optical transmitters and receivers.

- Military and Defense: Sealing components for sensitive electronics in harsh conditions.

EFTEKVAR

EFTEKVAR is a trademarked name for Kovar alloy developed by the Italian alloy manufacturer Aperam. Similar to ASTM F15 Kovar alloy, EFTEKVAR alloy exhibits excellent thermal expansion properties and weldability, often used for electronic device housings, packaging components, and leads.

F-30

F-30 is a trademarked name for Kovar alloy developed by Japan’s Sumitomo Metal Corporation. Similar to ASTM F15 Kovar alloy, F-30 alloy shares comparable thermal expansion coefficient and weldability properties, widely employed in electronic devices, vacuum technology, and optical devices.

The above descriptions outline some commonly used grades of Kovar alloy and their applications. It is important to note that different manufacturers may use different trademarked names for Kovar alloy, but their chemical composition and performance characteristics are generally similar. Due to its exceptional properties, Kovar alloy has become indispensable in many industries, providing reliable solutions for various applications.