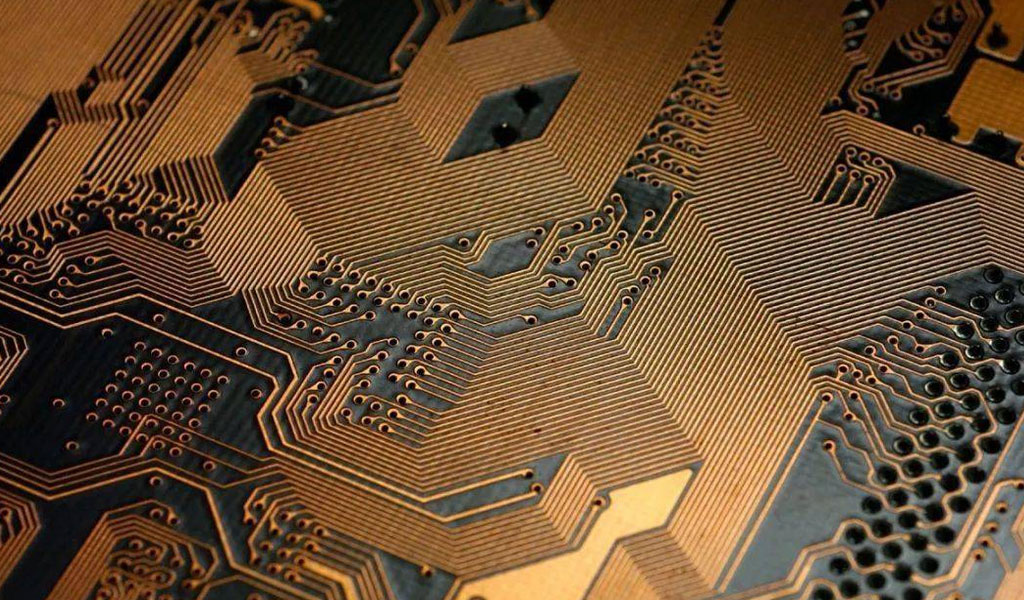

In the realm of modern electronics, the Printed Circuit Board (PCB) serves as a foundational component, acting as a platform for numerous electronic elements. However, the functionality and reliability of these devices can be compromised due to external electromagnetic interference (EMI) and radio frequency interference (RFI). To mitigate these issues, PCB shielding plays a pivotal role, ensuring optimal performance and longevity.

What Is PCB Shielding

PCB shielding refers to the process of implementing protective measures to safeguard electronic circuits from external electromagnetic interference and radio frequency interference. These interferences can emanate from various sources such as other electronic devices, power lines, wireless communication systems, and more. The shielding mechanisms are designed to contain electromagnetic emissions within the circuit and prevent external interferences from disturbing the functionality of the device.

Importance of PCB Shielding

The significance of PCB shielding cannot be overstated in the world of electronics. Its primary objective is to maintain signal integrity, reduce signal losses, and minimize the susceptibility of electronic circuits to external disturbances. Unchecked interference can lead to data corruption, signal distortion, reduced efficiency, and even complete device failure. Thus, implementing effective shielding strategies is fundamental in ensuring reliable device operation.

Understanding Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI)

EMI and RFI are two forms of interference that can detrimentally affect electronic circuits.

Electromagnetic Interference (EMI)

EMI refers to the disturbance caused by electromagnetic radiation that interferes with the normal operation of an electronic device. This interference can be conducted through wires or radiated through the air, affecting nearby electronic components and circuits. Sources of EMI include power lines, motors, electronic devices, and even natural phenomena like lightning.

Radio Frequency Interference (RFI)

RFI specifically pertains to interference caused by radio frequency signals. These signals can disrupt the functionality of wireless communication systems, including Wi-Fi networks, cellular devices, and radio receivers. RFI sources encompass various electronic devices, high-frequency transmitters, and other wireless communication systems.

PCB Shielding Materials and Techniques

Shielding Materials

- Metals: Common metals like aluminum, copper, and steel are widely used in PCB shielding due to their conductive properties. They form effective barriers against electromagnetic fields by reflecting or absorbing incoming interference.

- Conductive Coatings: Conductive coatings made of materials like nickel, silver, and conductive paints are applied to the PCB surface to create a shielding layer.

- Ferrite Materials: Ferrite materials, composed of iron oxide compounds, are effective in absorbing high-frequency interference.

Shielding Techniques

- Enclosures: Shielding enclosures or housings made of conductive materials envelop the entire PCB, creating a shielded environment to prevent external interference.

- Conductive Gaskets and Seals: These are used to seal gaps and connections in electronic enclosures to prevent leakage of electromagnetic radiation.

- Shielded Cables: Using shielded cables helps prevent interference from external sources by enclosing the signal-carrying conductors within a conductive shield.

Design Considerations for Effective PCB Shielding

Factors Influencing Shielding Effectiveness

- Material Selection: Choosing the right shielding material based on conductivity, flexibility, and cost-effectiveness.

- Placement and Enclosure Design: Proper positioning of shielding elements and the design of enclosures significantly impact shielding effectiveness.

- PCB Layout: The arrangement of components on the PCB can influence how susceptible the circuit is to interference.

Importance of PCB Layout and Design

Optimizing the PCB layout and design is crucial in enhancing shielding effectiveness. Techniques such as ground plane layout, signal trace routing, and minimizing loop areas help reduce susceptibility to interference. Moreover, separating analog and digital sections on the board and using differential signaling can further mitigate interference issues.

Testing and Validation of PCB Shielding

Methods for Testing Shielding Effectiveness

- Shielding Effectiveness Test: Conducting tests to measure the effectiveness of shielding materials and techniques in blocking electromagnetic radiation.

- Near-Field Scanning Techniques: Analyzing near-field radiation to identify weak points in shielding and areas susceptible to interference.

Industry Standards and Compliance Requirements

Adherence to industry standards and regulations ensures that electronic devices meet specific electromagnetic compatibility (EMC) requirements. Compliance with standards such as FCC (Federal Communications Commission) regulations and international standards like CISPR (International Special Committee on Radio Interference) helps validate the shielding effectiveness of electronic devices.

Importance of Validation

Validating the effectiveness of PCB shielding techniques through rigorous testing ensures that devices meet required standards and perform reliably in real-world conditions. This process helps identify any deficiencies and allows for necessary improvements in shielding strategies.

Challenges and Solutions in PCB Shielding

Common Challenges

- Miniaturization: Shrinking electronic devices pose challenges in implementing effective shielding strategies without compromising space or performance.

- Cost Considerations: Selecting cost-effective shielding solutions while maintaining high performance can be challenging.

- Heat Dissipation: Some shielding materials might hinder heat dissipation, leading to thermal management issues.

Solutions and Innovations

- Advanced Materials: Development of new materials with improved conductivity, flexibility, and thermal properties to address miniaturization and heat dissipation challenges.

- Simulation and Modeling: Using advanced simulation software to predict and optimize shielding effectiveness during the design phase.

- Integrated Shielding Solutions: Integration of shielding elements directly into PCB designs to minimize space requirements.

Application of PCB Shielding in Various Industries

Automotive Industry

PCB shielding is crucial in automotive electronics to prevent interference from the vehicle’s electrical systems, ensuring the reliability of safety-critical systems like ABS (anti-lock braking systems) and engine control units.

Aerospace and Defense

In aerospace and defense applications, shielding is vital to maintain communication systems, navigation equipment, and avionics free from interference, ensuring safe and reliable operation.

Telecommunications and Consumer Electronics

In telecommunications and consumer electronics, shielding ensures optimal performance of wireless communication devices, routers, smartphones, and other gadgets.

Conclusion

In conclusion, PCB shielding is a fundamental aspect of modern electronic design, protecting devices from electromagnetic and radio frequency interferences that could otherwise compromise their functionality. With the constant evolution of technology and the increasing complexity of electronic systems, the need for effective shielding techniques continues to grow. Advancements in materials, design methodologies, and testing techniques play a crucial role in addressing the challenges associated with PCB shielding, ensuring the reliability and performance of electronic devices across various industries.