An aperture diaphragm, often referred to simply as a diaphragm in the context of optics, plays a fundamental role in controlling the transmission of light in optical systems. This article explores the intricate mechanisms, applications, and significance of aperture diaphragms in the field of optics.

Overview and Basic Principles

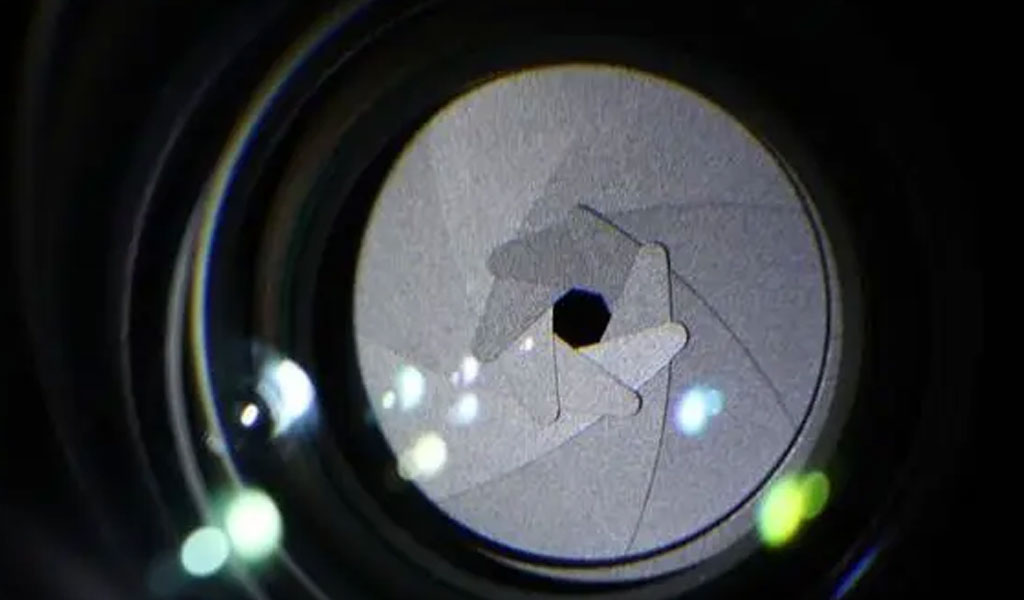

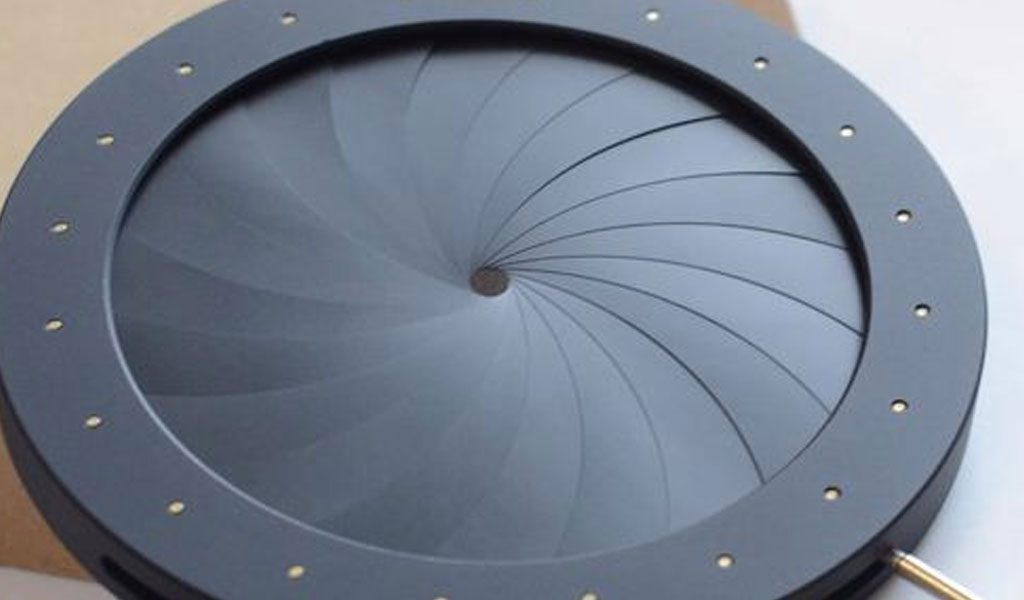

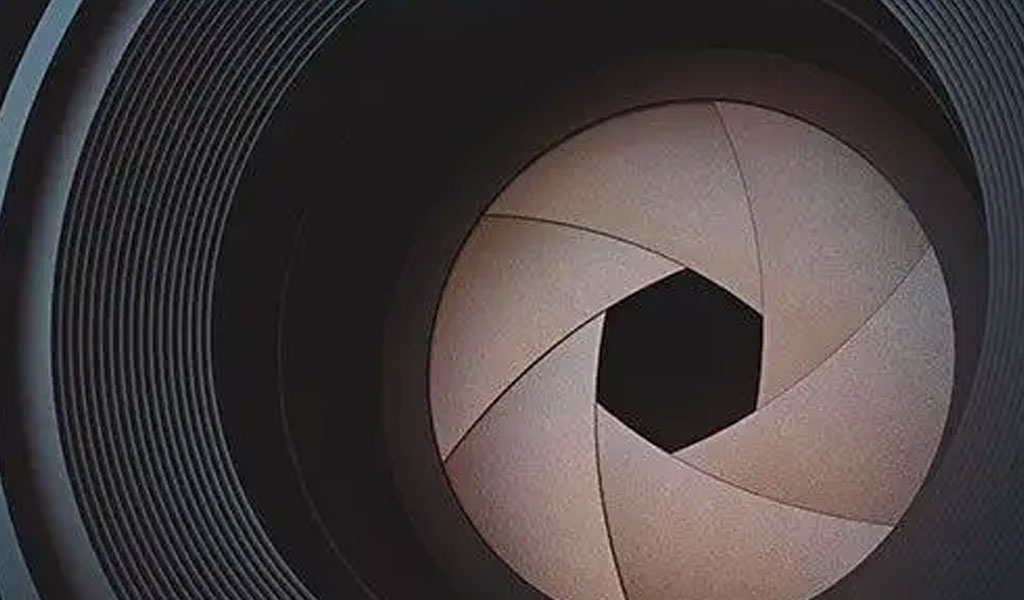

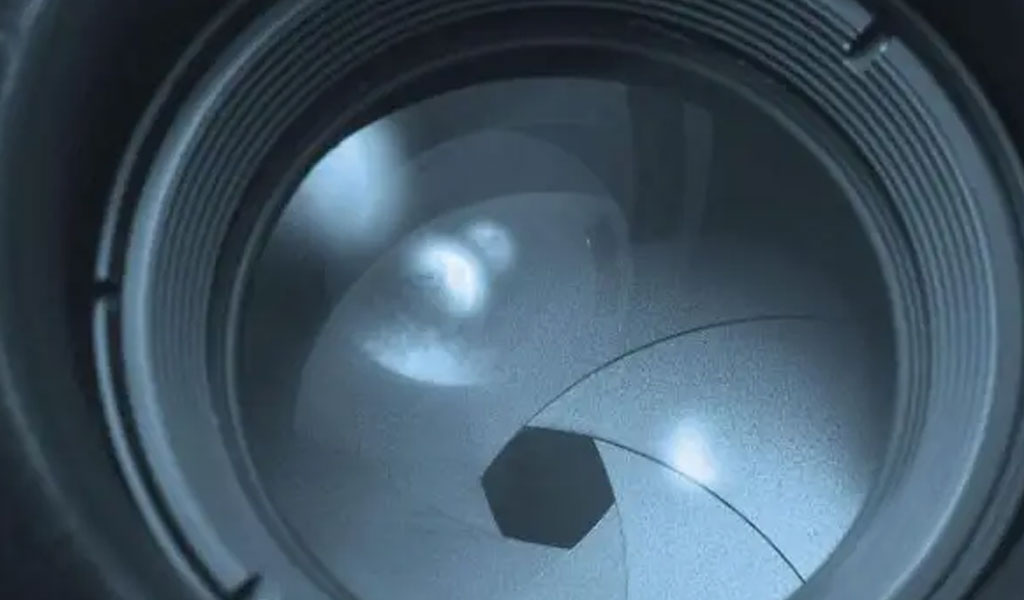

In optics, an aperture diaphragm serves as a mechanical device that regulates the amount of light passing through an optical system. It typically consists of a series of overlapping opaque and transparent blades arranged in a circular or polygonal shape.

The primary function of the diaphragm is to adjust the diameter of the aperture, thereby controlling the size of the light beam that can pass through the system.

Construction and Design

Aperture diaphragms are commonly constructed from materials such as metal or synthetic polymers that exhibit both durability and precision in manufacturing. The blades are meticulously engineered to move smoothly and uniformly, ensuring consistent adjustment of the aperture size without introducing optical aberrations.The design of aperture diaphragms varies based on the specific optical system requirements. For instance, some diaphragms are designed with straight blades, while others incorporate curved or rounded edges to minimize diffraction effects when the aperture is stopped down to smaller sizes.

Functionality and Operation

The operation of an aperture diaphragm revolves around its ability to alter the diameter of the aperture opening. By adjusting the size of the aperture, the diaphragm controls several critical aspects of light transmission:

- Light Intensity: The aperture regulates the amount of light that enters the optical system. Larger apertures allow more light to pass through, while smaller apertures restrict the amount of incoming light.

- Depth of Field: In photography and microscopy, adjusting the aperture size influences the depth of field—the range of distance over which objects appear sharp in an image. Larger apertures (smaller f-numbers) produce shallow depth of field, whereas smaller apertures (larger f-numbers) increase depth of field.

- Image Quality: The size of the aperture affects the quality of the image formed by the optical system. Extreme aperture settings (very large or very small) can introduce optical aberrations such as spherical aberration, coma, and diffraction, which may degrade image sharpness and clarity.

Applications in Different Optical Systems

The role of aperture diaphragms extends across various fields of optics, each demanding precise control over light transmission for optimal performance. Key applications include:

Photography

In photography, aperture diaphragms are integral components of camera lenses.

Photographers utilize aperture settings to achieve specific artistic effects, control exposure levels, and manipulate depth of field.

Modern camera systems often feature adjustable diaphragms that allow seamless adjustment between different aperture sizes.

Microscopy

In microscopy, aperture diaphragms are essential for optimizing image contrast and resolution. Microscopes utilize diaphragms to adjust the amount of illumination reaching the specimen, thereby enhancing visibility and detail in microscopic images. Advanced microscopy techniques, such as confocal microscopy, rely on precise diaphragm control to achieve high-resolution imaging.

Telescopes and Astronomical Instruments

Telescopes and astronomical instruments utilize aperture diaphragms to enhance observational capabilities. By adjusting the aperture size, astronomers can control the amount of light captured from celestial objects, optimize image clarity, and improve the detection of faint astronomical phenomena. Aperture diaphragms are crucial in minimizing optical aberrations that can affect the accuracy of astronomical observations.

Optical Instruments and Laser Systems

In industrial and scientific optical instruments, as well as laser systems, aperture diaphragms serve critical functions in beam shaping, collimation, and controlling light propagation. Precision diaphragms enable engineers and researchers to manipulate laser beams for specific applications such as laser cutting, material processing, and scientific experiments requiring controlled light intensities.

Advanced Concepts and Innovations

Recent advancements in optics have led to innovations in aperture diaphragm technology, aiming to improve efficiency, precision, and versatility in optical systems:

- Variable Aperture Systems: Some optical systems incorporate variable aperture diaphragms that can dynamically adjust aperture size in response to changing lighting conditions or operational requirements.

- Apodization: Apodizing aperture diaphragms are designed with non-uniform transmission characteristics, enabling enhanced image quality by reducing the impact of optical aberrations at larger aperture sizes.

- Smart Diaphragm Control: Integration of electronic controls and feedback mechanisms allows for automated adjustment of aperture diaphragms in real-time, based on computational analysis or user-defined parameters.

How To Precision Etching Aperture Diaphragms

Precision etching of aperture diaphragms involves several key steps and considerations to ensure accuracy and reliability in optical systems. This process is crucial in manufacturing aperture diaphragms with precise dimensions and smooth edges, minimizing optical aberrations and ensuring consistent performance. Here’s a detailed guide on how to achieve precision etching of aperture diaphragms:

Materials and Tools Needed:

- Substrate Material: Typically metal alloys such as stainless steel, aluminum, or nickel are used due to their durability and machinability.

- Photoresist Material: A photosensitive material that coats the substrate and is used to define the pattern for etching.

- Mask: A high-resolution mask with the desired pattern of the aperture openings, used during the photolithography process.

- Etchant: Chemical solution capable of selectively removing material from the substrate to create the aperture pattern.

- Developing Chemicals: Used to remove the exposed or unexposed photoresist after etching.

- Cleaning Solutions: Solvents for cleaning the substrate before and after the etching process.

- UV Light Source: Used to expose the photoresist through the mask during photolithography.

- Etching Equipment: Includes tanks or baths for immersion etching or equipment for dry etching processes.

Step-by-Step Guide

Here’s a step-by-step guide to precision etching aperture diaphragms:

- 1. Substrate Preparation

- 2. Coating with Photoresist

- 3. Photolithography

- 4. Developing

- 5. Etching

- 6. Post-Etching Processing

- 7. Final Inspection and Quality Assurance

- 8. Packaging and Storage

Precision etching of aperture diaphragms is a meticulous process that demands expertise in materials science, photolithography, and chemical engineering. By following these steps and considerations, manufacturers can produce high-quality aperture diaphragms essential for diverse applications in optics, ensuring optimal performance and reliability in optical systems.

Conclusion

In conclusion, aperture diaphragms represent indispensable components in the realm of optics, serving multifaceted roles in controlling light transmission across various optical systems. From photography and microscopy to astronomy and laser technology, the precise adjustment of aperture size enables professionals and researchers to optimize performance, enhance image quality, and expand the boundaries of optical exploration. As optical sciences continue to evolve, so too will the sophistication and applications of aperture diaphragms, reinforcing their pivotal role in shaping the future of optics and photonics.

This comprehensive overview underscores the significance of aperture diaphragms as foundational elements in optical engineering, blending precision mechanics with the pursuit of clearer, sharper, and more illuminating perspectives on the world and the cosmos beyond.