Surface finishes play a pivotal role in the functionality, aesthetics, and longevity of metal parts produced through etching processes. Metal etching, a subtractive manufacturing technique that selectively removes material to create intricate designs or components, often leaves surfaces with specific textures that may require further treatment to meet end-use requirements. This article explores the common types of surface finishes applicable to etched metal parts, delving into their characteristics, applications, and selection criteria. Drawing from engineering principles, material science, and industrial practices, it adopts a comprehensive, neutral tone akin to encyclopedic resources, providing detailed explanations, comparative analyses via tables, and practical guidance.

The discussion emphasizes the interplay between etching methods—such as chemical, photochemical, electrochemical, and laser etching—and subsequent finishing techniques, highlighting how these enhance corrosion resistance, wear properties, visual appeal, and overall performance. While etching itself can impart a finish, this article focuses primarily on post-etching treatments, acknowledging variations across metals like aluminum, stainless steel, copper, and titanium. Through periodic headings and subsections, the content is structured for readability and scientific rigor, facilitating navigation for researchers, engineers, and practitioners alike.

The importance of surface finishes cannot be overstated in industries ranging from aerospace and electronics to automotive and medical devices, where etched parts often serve critical roles. For instance, in microelectronics, etched metal meshes or filters demand finishes that prevent oxidation while maintaining dimensional precision. This preface sets the stage for an in-depth examination, beginning with foundational concepts and progressing to advanced considerations. Readers will find that selecting the right finish involves balancing factors such as environmental exposure, mechanical stresses, regulatory compliance, and economic feasibility. By the end, one should possess a thorough understanding to make informed decisions, supported by empirical data and comparative frameworks.

Introduction to Metal Etching and Surface Finishes

Metal etching is a versatile fabrication method that has evolved from ancient artisanal practices to modern precision engineering.

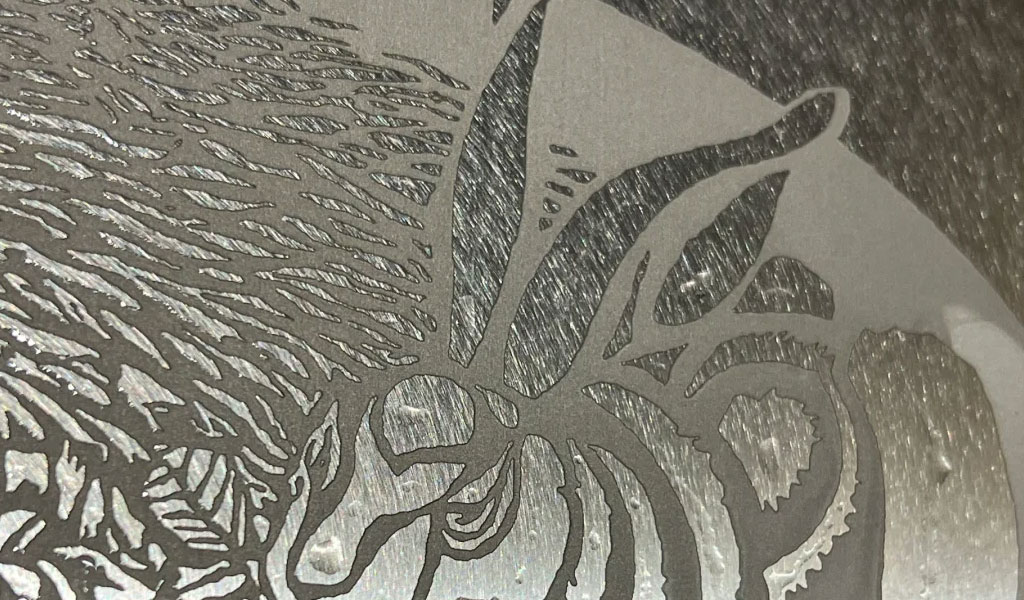

At its core, etching involves the controlled corrosion or ablation of metal surfaces using chemical agents, lasers, or electrochemical processes to produce patterns, cavities, or thinned sections. Common etching techniques include wet chemical etching, where acids like ferric chloride dissolve unprotected areas; dry etching, often plasma-based for semiconductors; photochemical etching, which uses photoresists for high-resolution patterns; and laser etching, which vaporizes material with focused beams.

Surface finishes for etched metal parts refer to the treatments applied post-etching to modify the topography, chemistry, or appearance of the surface. These finishes serve multiple purposes: protecting against environmental degradation, improving adhesion for coatings or assemblies, enhancing optical properties, or achieving specific tribological behaviors. For example, an etched aluminum part might receive anodizing to form a durable oxide layer, while a stainless steel component could undergo passivation to bolster its natural corrosion resistance. The choice of finish is influenced by the base metal’s properties—aluminum’s reactivity versus titanium’s inertness—and the etching method’s impact on surface integrity.

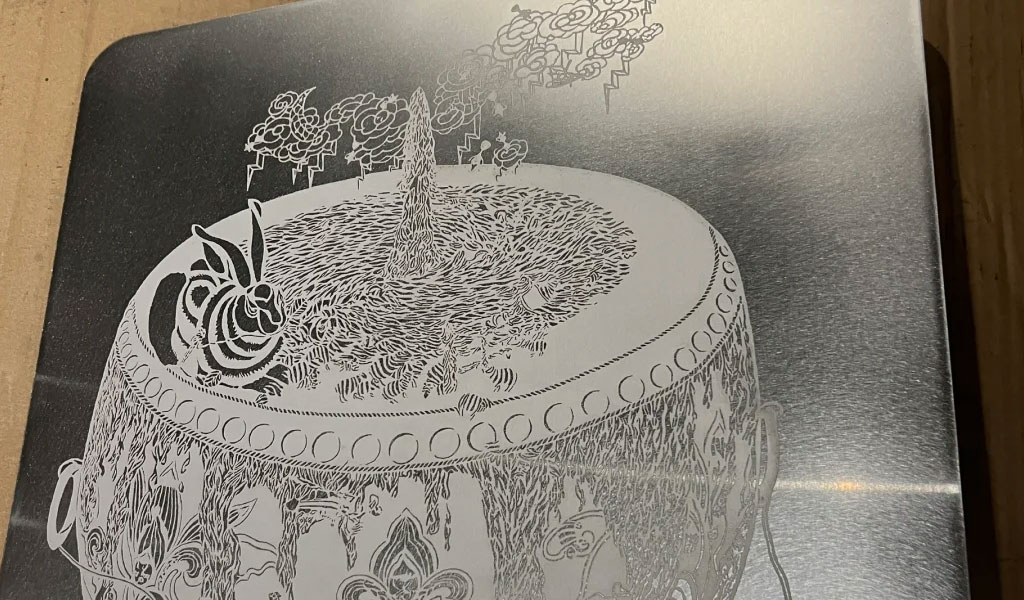

In historical context, early etching dates back to the Renaissance, where artists like Albrecht Dürer used acid etching on copper plates for printmaking. Industrial adoption surged in the 20th century with photochemical etching for circuit boards and aerospace components. Today, finishes are integral to meeting standards like ISO 4287 for surface roughness or ASTM B117 for corrosion testing. This introduction underscores that while etching creates the form, finishes define the function, setting the foundation for exploring common types.

Text preceding this subsection highlights that roughness influences friction, fluid flow, and fatigue life. For etched parts, initial roughness from etching must be assessed via profilometers or atomic force microscopy. Finishes like polishing can reduce Ra to below 0.05 µm for mirror-like surfaces, whereas bead blasting increases it for better paint adhesion. Understanding these fundamentals aids in selecting finishes that align with design tolerances.

History of Metal Etching and Associated Surface Finishes

The evolution of metal etching parallels advancements in chemistry and materials science. Ancient civilizations etched metals using natural acids, such as vinegar on iron, for decorative purposes. By the 15th century, intaglio printmaking refined etching techniques, with artists applying wax resists and ferric chloride etches on copper. Surface finishes were rudimentary, often limited to manual polishing or patination.

The Industrial Revolution introduced electrochemical etching, pioneered by Michael Faraday’s work on electrolysis in the 1830s, enabling precise control over material removal. Post-etching finishes like electroplating emerged in the 1840s, with Henry Elkington’s patent for gold plating. In the 20th century, photochemical etching, developed during World War II for radar components, necessitated finishes like passivation to prevent corrosion in harsh environments.

Modern developments include laser etching in the 1970s, which minimizes chemical use and allows for nanoscale precision, often followed by anodizing or powder coating. Regulatory pressures, such as RoHS directives limiting hazardous substances, have shifted finishes toward eco-friendly options like electroless nickel. This historical overview illustrates how etching and finishing have co-evolved, driven by technological needs and material innovations.

The Science Behind Surface Finishes in Metal Etching

Surface finishes alter the physical and chemical properties of etched metal surfaces through mechanisms like oxidation, deposition, or mechanical abrasion. Scientifically, etching exposes fresh metal atoms, increasing reactivity; finishes mitigate this by forming barriers or modifying topography.

For instance, anodizing involves electrolytic oxidation, where aluminum forms Al2O3 layers via Faraday’s laws, with thickness controlled by voltage and time. Passivation leverages chromium oxide formation on stainless steel, following Pourbaix diagrams that map pH-potential stability. Mechanical finishes like polishing reduce asperities, minimizing stress concentrations per Griffith’s fracture theory.

Adhesion of finishes to etched surfaces depends on surface energy and wetting angles, governed by Young’s equation. Corrosion resistance follows Tafel kinetics, where finishes shift polarization curves. This scientific foundation explains why certain finishes suit specific etchants—e.g., avoiding chloride-based etches before passivation to prevent pitting.

Common Types of Surface Finishes for Etched Metal Parts

Etched metal parts benefit from a variety of surface finishes, each tailored to enhance specific attributes. Below, we detail common types, starting with mechanical finishes and progressing to chemical and electrochemical ones. These are selected based on the etching method and part geometry, as intricate etched features may limit aggressive treatments.

Mechanical Finishes

Mechanical finishes involve physical alteration of the surface without chemical reactions, ideal for controlling roughness post-etching.

Polishing is a primary mechanical finish, achieved through abrasive pads or buffs to create smooth, reflective surfaces. For etched parts, it removes burrs and etch residues, achieving Ra < 0.1 µm. Applications include optical components where low scatter is crucial.

Brushing uses wire brushes or belts to impart directional grains, enhancing aesthetics while hiding minor etch imperfections. Common on stainless steel, it provides a satin finish with Ra 0.2-0.5 µm.

Bead blasting propels glass or ceramic beads at the surface, creating a matte texture (Ra 0.8-2.5 µm) for improved grip or coating adhesion. It’s suitable for etched aluminum to mask tool marks.

Chemical Finishes

Chemical finishes react with the metal surface, often enhancing corrosion resistance.

Passivation treats stainless steel with nitric or citric acid to form a chromium-rich oxide layer, typically 1-3 nm thick. For etched parts, it restores passivity lost during aggressive etching, per ASTM A967 standards.

Phosphating immerses parts in phosphate solutions, forming crystalline coatings for rust prevention and paint priming. On etched steel, it provides a porous surface for lubrication retention.

Alodine (chromate conversion) applies a thin chromate film on aluminum, offering conductivity and corrosion protection. It’s lighter than anodizing, ideal for etched electrical contacts.

Electrochemical Finishes

These use electricity to deposit or oxidize layers, providing durable protection.

Anodizing, primarily for aluminum, creates porous oxide layers (5-25 µm) dyed for color. Type II (sulfuric acid) suits decorative etched parts, while Type III (hard anodizing) offers wear resistance for functional components.

Electroplating deposits metals like nickel or chrome via electrolysis. For etched copper parts, it enhances conductivity and solderability.

Electroless plating autocatalytically deposits nickel-phosphorus alloys, uniform on complex etched geometries without electricity.

Advanced and Specialized Finishes

Powder coating electrostatically applies polymer powders, baked for a tough finish. Post-etching, it’s used on larger parts for UV resistance.

Black oxide forms magnetite on steel via hot alkaline solutions, providing mild corrosion protection and a black appearance for etched tools.

Laser etching as a finish itself creates permanent marks without additional treatments, though often combined with others.

Comparative Analysis of Surface Finishes

To facilitate selection, comparative tables are provided, drawing from industry data on properties like durability, cost, and compatibility.

Table 1: Comparison of Mechanical Finishes

| Finish Type | Roughness (Ra, µm) | Durability (Corrosion Resistance) | Cost (Relative) | Suitable Metals | Applications in Etched Parts |

|---|---|---|---|---|---|

| Polishing | 0.05-0.2 | Low (no added protection) | Medium | All | Mirrors, optics |

| Brushing | 0.2-0.8 | Medium | Low | Stainless, Al | Decorative panels |

| Bead Blasting | 0.8-3.0 | Low | Low | Al, Steel | Grippy surfaces, prep for coating |

This table illustrates that mechanical finishes prioritize aesthetics and texture over protection, making them first-step treatments for etched parts.

Table 2: Comparison of Chemical and Electrochemical Finishes

| Finish Type | Thickness (µm) | Corrosion Resistance | Wear Resistance | Cost (Relative) | Etching Compatibility |

|---|---|---|---|---|---|

| Passivation | 0.001-0.003 | High | Low | Low | Excellent for chemical etched SS |

| Anodizing (Type II) | 5-15 | High | Medium | Medium | Good for photoetched Al |

| Electroplating (Ni) | 10-50 | Very High | High | High | Suitable for laser etched Cu |

| Powder Coating | 50-100 | High | High | Medium | Best for larger etched parts |

Data sourced from general industry standards; actual values vary by process parameters.

Table 3: Environmental and Performance Metrics

| Finish | Environmental Impact | Heat Resistance (°C) | Electrical Conductivity | Aesthetic Options |

|---|---|---|---|---|

| Phosphating | Medium (phosphates) | Up to 150 | Low | Limited |

| Black Oxide | Low | Up to 200 | Medium | Black only |

| Electroless Plating | Medium (chemicals) | Up to 400 | High | Metallic |

These tables enable side-by-side evaluation, revealing trade-offs like anodizing’s superior corrosion resistance versus polishing’s simplicity.

How to Choose the Right Surface Finish for Etched Metal Parts

Selecting a surface finish requires a systematic approach, considering the part’s intended use, material, and etching history. Begin by defining requirements: Does the part need high corrosion resistance for marine environments, or low friction for sliding mechanisms?

Evaluate material compatibility—aluminum favors anodizing, while steel suits phosphating. Consider etching effects: Chemical etching may leave residues necessitating cleaning before finishing.

Factor in environmental conditions using standards like MIL-STD-810 for testing. Cost-benefit analysis includes initial setup versus long-term savings from durability. Aesthetic needs, such as color or texture, guide choices like dyeing in anodizing.

Consult guidelines from bodies like ASM International. For complex parts, prototype testing ensures finish adhesion, using peel tests or salt spray exposure.

Step-by-Step Selection Process

- Assess functional needs (e.g., wear, conductivity).

- Match to metal type and etching method.

- Compare options via tables.

- Evaluate cost and scalability.

- Validate with simulations or trials.

This process ensures optimal choice, minimizing failures.

Applications of Surface Finishes in Etched Metal Parts

Etched parts with appropriate finishes find use across sectors. In aerospace, anodized etched aluminum shims resist fatigue. Electronics employ passivated etched copper traces for reliability. Medical devices use electropolished etched titanium for biocompatibility.

Automotive applications include powder-coated etched steel brackets for vibration resistance. Consumer goods feature brushed etched stainless for appliances.

Industry-Specific Examples

In microfluidics, bead-blasted etched channels improve flow. Defense uses black oxide on etched weapon components for stealth.

Case Studies in Surface Finish Selection

Case 1: An electronics firm etched PCB stencils from stainless steel, applying passivation to prevent oxidation, extending life by 50%.

Case 2: Aerospace manufacturer used hard anodizing on photoetched titanium filters, enhancing abrasion resistance for engine applications.

These illustrate real-world decisions.

Future Trends in Surface Finishes for Etched Metals

Emerging trends include nanotechnology for self-healing finishes and eco-friendly processes like water-based anodizing. AI-driven optimization predicts finish performance.

Innovations on the Horizon

Plasma-enhanced finishes and 3D-printed coatings promise customization for etched complexities.