In an era where technology has become an integral part of our daily lives, the quest for efficient and durable tagging systems has gained paramount importance across various industries. One such innovation that has emerged as a reliable solution is the Etch tag. Designed to endure harsh environments while retaining crucial information, Etch tags have sparked widespread interest due to their durability, adaptability, and versatile applications.

Understanding Etch Tags

In an age where efficient tagging and identification systems are essential across various sectors, Etch tags have emerged as a dependable solution known for their durability, resilience, and adaptability. To truly grasp the significance and functionality of Etch tags, it’s crucial to delve deeper into their composition, creation process, and applications.

What are Etch Tags?

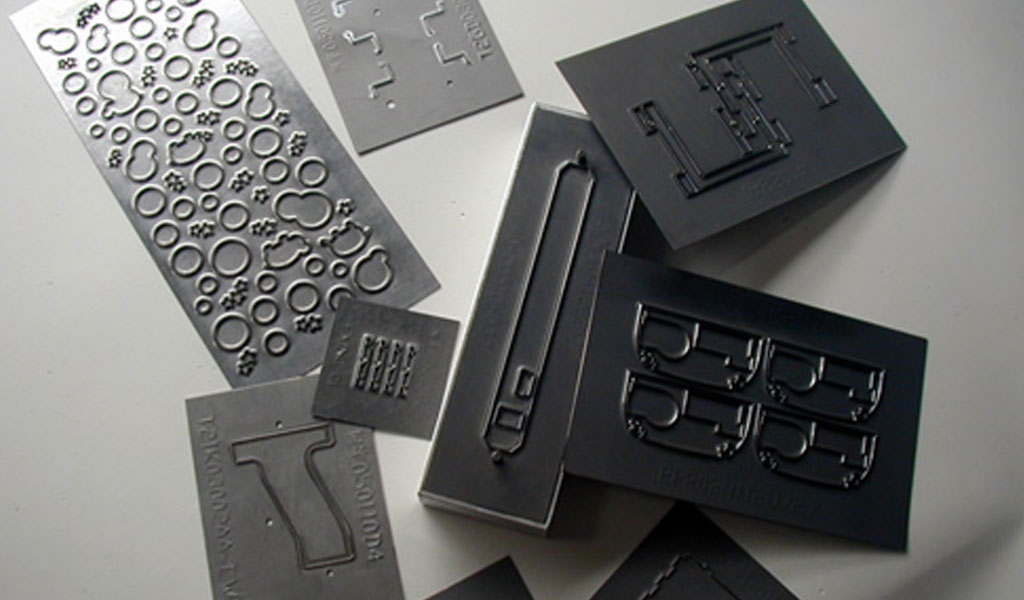

Etch tags, also referred to as etched metal tags, are small, durable markers made from metals like stainless steel, aluminum, brass, or titanium. These tags are crafted by employing a process called chemical etching or acid etching, where a chemical solution is used to remove specific areas of the metal, leaving behind a precise and legible design or text.

The Making of Etch Tags

The process of creating Etch tags involves several intricate steps. Initially, a metal sheet is cleaned thoroughly to remove any impurities or contaminants. Following this, a protective layer of photo-resistant material is applied to the metal surface. A design or text is then printed onto this protective layer using a high-resolution printer or a photomask.

Next, the metal sheet undergoes a chemical etching process. The areas not covered by the printed design are exposed to a chemical solution, which selectively dissolves the exposed metal. This results in the desired design or text being etched onto the metal surface. Finally, the protective layer is removed, leaving behind a durable and precise Etch tag.

Importance of Etch Tags

Etch tags stand as a testament to reliability and durability in the realm of identification and tagging systems. Their significance transcends mere labeling; it lies in their unparalleled attributes and their ability to address critical needs across various industries. Let’s delve deeper into the crucial aspects that underline the importance of Etch tags:

Durability and Resistance

One of the primary reasons for the widespread use and importance of Etch tags is their exceptional durability and resistance to various environmental factors. These tags are built to withstand extreme temperatures, moisture, chemicals, abrasion, and UV exposure, making them suitable for use in challenging conditions where conventional tags might fail.

Legibility and Longevity

The etching process ensures that the information engraved on Etch tags remains highly legible and long-lasting. Unlike printed labels that may fade or wear off over time, the etched designs on these tags are deeply embedded into the metal, ensuring readability and longevity, even in harsh environments.

Versatility in Applications

The versatility of Etch tags makes them indispensable across diverse industries. From industrial equipment and machinery to aerospace, automotive, military, and medical sectors, these tags find applications in various settings. They serve multiple purposes such as asset tracking, product identification, serial numbering, labeling critical components, and more.

Compliance and Traceability

Etch tags play a pivotal role in compliance and traceability standards within industries. They help meet regulatory requirements by providing permanent identification and tracking of assets or components, ensuring adherence to quality control protocols, safety regulations, and product certifications.

Customization and Adaptability

Another significant aspect of Etch tags is their customization capability. They can be tailored to meet specific size, shape, and design requirements, allowing companies to incorporate logos, barcodes, serial numbers, or other essential information onto the tags, enhancing brand identity and facilitating seamless inventory management.

Applications of Etch Tags

The versatility and durability of Etch tags render them invaluable across a multitude of industries, offering solutions to diverse identification and labeling needs. Their adaptability to harsh environments and their ability to maintain precise information make them indispensable in various sectors. Let’s explore the extensive range of applications where Etch tags play a pivotal role:

Aerospace and Defense

In the aerospace and defense industries, where precision, reliability, and safety are paramount, Etch tags find extensive use. These tags are utilized for labeling aircraft components, tools, and equipment. They withstand extreme temperatures, corrosive environments, and mechanical stress, ensuring crucial information remains intact for maintenance, safety, and compliance purposes.

Healthcare and Medical Devices

Etch tags play a crucial role in the healthcare sector by providing permanent identification for surgical instruments, medical devices, and equipment. Their resistance to harsh sterilization processes and cleaning agents ensures that essential information remains legible, contributing to accurate tracking and inventory management in clinical settings.

Industrial Machinery and Equipment

In industrial settings, Etch tags are instrumental in identifying and tracking machinery parts, valves, pipelines, and various components. Their durability enables consistent identification, aiding in maintenance schedules, inventory management, and ensuring seamless operational processes in manufacturing units.

Automotive Industry

Within the automotive sector, Etch tags are utilized for product identification, part numbering, and traceability during the assembly and manufacturing of vehicles. These tags endure the rigors of automotive assembly lines and harsh operating conditions, providing reliable identification and aiding in quality control processes.

Manufacturing and Engineering

Etch tags play a vital role in manufacturing and engineering industries by labeling tools, equipment, and components. They facilitate easy identification, traceability, and compliance with regulatory standards, ensuring efficient production processes and minimizing errors in large-scale manufacturing operations.

Electrical and Electronics

Etch tags are used in electrical and electronics industries to label components, circuit boards, and electronic devices. Their resistance to chemicals, heat, and environmental factors ensures that crucial information remains intact, contributing to the safety and reliability of electrical systems and devices.

Asset Tracking and Inventory Management

In addition to specific industries, Etch tags are employed for broader purposes such as asset tracking and inventory management across various sectors. Their durability and permanence make them ideal for long-term asset identification, aiding in inventory control, logistics, and supply chain management.

Custom and Specialized Applications

The adaptability of Etch tags allows for specialized applications, including labeling in harsh outdoor environments, underwater equipment, and high-temperature settings. Their customization capabilities enable the incorporation of specific designs, serial numbers, barcodes, or logos tailored to unique industry requirements.

Conclusion

Etch tags stand as a testament to the intersection of innovation and durability. Their ability to endure harsh conditions while maintaining precise information makes them invaluable across diverse sectors. As industries continue to evolve and demand robust identification and tracking solutions, Etch tags remain an essential component, ensuring compliance, traceability, and reliability in an ever-changing landscape of technological advancements.

In essence, the enduring nature of Etch tags echoes their significance in preserving information—a testament to their indispensable role in various industries, promising an enduring legacy in the realm of durable tagging solutions.