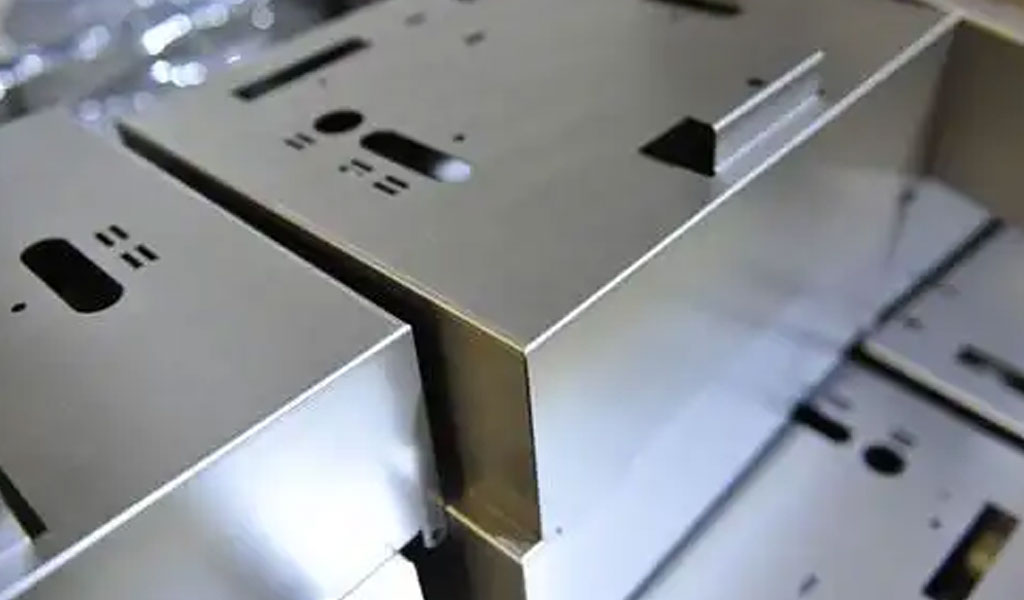

Metal etching, a process that uses chemicals or lasers to engrave intricate patterns or designs onto metal surfaces, plays an essential role in enhancing the performance, aesthetics, and longevity of various bicycle components.

The versatility of metal etching allows for the creation of highly detailed, durable, and functional designs, which can be applied to a wide range of materials commonly used in bicycle manufacturing, such as steel, aluminum, titanium, and stainless steel. This article explores the top 20 metal etching applications for bicycles, focusing on both functional and decorative uses within the cycling industry.

Bicycle Frame Marking and Branding

One of the most common applications of metal etching in the bicycle industry is for frame marking and branding. Manufacturers often use metal etching to apply logos, model names, serial numbers, and other branding elements to the frame of the bicycle. Etching ensures that these markings are permanent, highly resistant to wear, and not easily removed, making it ideal for ensuring traceability and brand identity. This is particularly important for high-end bicycles where brand recognition and authenticity are key factors for consumers.

Component Serial Numbers for Tracking and Identification

Metal etching is widely used to engrave serial numbers and identification codes on critical bicycle components, such as the frame, wheels, and handlebars. These markings help with tracking parts for warranty purposes, theft prevention, and quality control. Etched serial numbers are much more difficult to alter or remove compared to traditional printing methods, providing an added layer of security and reliability for both manufacturers and consumers.

Custom Bicycle Frame Designs

Bicycle enthusiasts often seek custom designs for their bicycles, which can be achieved through metal etching. This process allows for intricate artwork or custom patterns to be etched directly onto the bicycle frame. These custom designs can range from simple geometric patterns to highly detailed illustrations, enabling manufacturers or individual riders to create unique, personalized bicycles that stand out in terms of aesthetics and style.

Brake Rotors and Discs Etching

Brake components, such as brake rotors and discs, benefit from metal etching in both functional and decorative aspects. Functional etching on brake discs can improve the performance of the braking system by increasing friction, enhancing heat dissipation, and reducing brake fade. In addition to functional benefits, decorative etching can be used to add intricate designs or branding elements to the rotors, enhancing the overall look of the bicycle’s braking system.

Chainrings and Cranksets Etching

Chainrings and cranksets, which are essential components of a bicycle’s drivetrain, are frequently etched for both decorative and functional purposes. Etching can improve the aesthetics of these parts by incorporating branding logos, designs, or text. Functional etching can also be used to increase surface texture and enhance grip on certain areas of the crankset, contributing to better pedaling efficiency and performance.

Saddle Rails and Seatposts Etching

Metal etching is used on saddle rails and seatposts to apply branding, model names, and other markings, ensuring durability and long-lasting visibility. These components are critical for the comfort and safety of the rider, and etching helps identify key details such as material composition or sizing, ensuring proper installation and usage. Additionally, decorative etching on these parts can enhance the overall appearance of the bike.

Pedals Etching

Pedals, an essential part of a bicycle’s drivetrain, often undergo metal etching for a variety of reasons. Functional etching on pedal surfaces can increase grip, preventing slippage during use, especially in wet conditions. Additionally, decorative etching can be applied to the pedal body for branding or custom design purposes, making the pedals visually appealing while still serving their functional role.

Wheel Hubs and Axles Etching

Wheel hubs and axles are critical for the bicycle’s performance and structural integrity. Etching can be used to mark these components with serial numbers, brand logos, or other identifying features. Etching these components not only provides a professional and polished look but also ensures they are easily identifiable for maintenance, repair, and warranty purposes. Etching can also be used to add texture to certain areas of the hubs to enhance grip or friction as needed.

Handlebars Etching

Etching handlebars serves both functional and aesthetic purposes. Functional etching on handlebars can improve grip, providing a textured surface to prevent hands from slipping during rides. On the other hand, decorative etching can be used to apply custom designs, logos, or other artistic elements to enhance the bike’s visual appeal. Handlebars, being an integral part of the rider’s control, benefit from the added durability and strength provided by etching processes, especially in high-performance models.

Tires and Inner Tubes Marking

While less common, metal etching is sometimes used for marking tires and inner tubes. This process can be employed to engrave important information such as tire pressure recommendations, brand names, and model numbers. In some cases, etching can also be used for special patterns or designs that enhance the tire’s performance by increasing surface friction or optimizing traction.

Reflective Elements and Safety Markings

Reflective elements, such as those found on pedals, frames, or wheels, are essential for the safety of cyclists, especially in low-light conditions. Metal etching allows for the precise application of reflective materials onto metal surfaces. In addition, safety-related markings such as warning labels, cautionary symbols, or reflective stripes can be etched onto bicycle components, ensuring the rider’s visibility and promoting road safety.

Forks Etching

Bicycle forks, which play a critical role in steering and shock absorption, can also benefit from metal etching applications. Functional etching on the fork steerer tube or dropouts can be used to mark measurements, serial numbers, or installation instructions. Decorative etching can enhance the fork’s appearance by incorporating logos or designs that complement the overall aesthetics of the bike. Additionally, etching can help reduce weight in certain areas, as precision etching removes excess material without compromising structural integrity.

Shock Absorber and Suspension Components Etching

Suspension components such as shocks and dampers can undergo metal etching for a variety of reasons. Etching is often used to mark important details such as model numbers, adjustment settings, and performance characteristics. These etchings allow for easier maintenance and fine-tuning, as well as providing an aesthetic finish. Etched suspension components may also feature custom designs or logos that align with the bicycle’s overall look.

Bottle Cages Etching

Bottle cages, which hold water bottles or hydration systems on a bicycle, can be enhanced with metal etching. Etching can be used for branding purposes or to apply custom designs, adding a touch of uniqueness to this functional component. In some cases, etching may also be used for improving grip or texture on the cage, ensuring that the bottle stays securely in place during the ride.

Rims and Spokes Etching

Metal etching is used to mark and enhance bicycle rims and spokes. Rims, especially those made from high-grade aluminum or carbon composites, can feature etched logos, serial numbers, or decorative patterns. Spokes may also be etched with custom markings, identifying the brand or specific model. Etching can also serve a functional purpose on rims, such as improving surface textures to help with braking efficiency or to optimize aerodynamics.

Brake Calipers Etching

Brake calipers, the components responsible for applying pressure to the brake pads, can benefit from metal etching for both identification and performance purposes. Manufacturers may use etching to mark the model and brand name, ensuring proper identification. Decorative etching can also be applied to the surface of the caliper for a more polished and stylish appearance. In some instances, functional etching may be used to enhance heat dissipation, ensuring the brake caliper maintains optimal performance during long descents or intense use.

Suspension Linkages Etching

Suspension linkages are part of a bicycle’s rear shock system, and they are often etched with identifying marks and brand logos. Etching these components ensures that important technical details, such as the type of suspension and its specifications, are easily accessible. Additionally, decorative etching can be used to personalize the linkage or to integrate it seamlessly with the bicycle’s overall design.

Bell and Horn Etching

Though more often used for decorative purposes, metal etching can be applied to the bells and horns found on bicycles. Custom logos, text, or designs can be etched onto the metal parts of these components, enhancing the appearance while ensuring their durability. Additionally, etching can improve grip or texture on the bell’s striking surface, optimizing sound quality or the ease with which the bell is used.

Custom Pedal Straps and Clips Etching

Pedal straps and clips, which secure the rider’s feet to the pedals, can be customized through metal etching. Manufacturers often etch their logos or other designs onto these parts, providing a unique touch that enhances the aesthetics of the bike. Additionally, functional etching can be used to create grooves or textured areas on the straps, improving grip and comfort for the rider.

Protective Skid Plates Etching

Skid plates are protective components found on the underside of bicycles, particularly in mountain and downhill bikes. Metal etching is often used to mark the plate’s material, size, and other identifying features, ensuring it is properly installed and maintained. Additionally, etching can add decorative patterns, logos, or unique identifiers that help the rider distinguish between different protective plates or models.

In conclusion, metal etching serves a broad range of applications in the bicycle industry, from improving the performance of critical components to enhancing the aesthetic appeal of the bicycle. The versatility and precision of metal etching make it a valuable tool for manufacturers, riders, and enthusiasts alike. Whether for branding, customization, or functional enhancement, the use of metal etching in bicycles continues to evolve, offering new possibilities for design, performance, and safety.