The automotive metal speaker mesh often uses an etching process due to several reasons related to its advantages in manufacturing and design. Etching refers to the process of using chemical or physical methods to remove material from a metal surface to create a desired design or pattern. Here are some of the reasons why the automotive industry employs the etching process for speaker mesh:

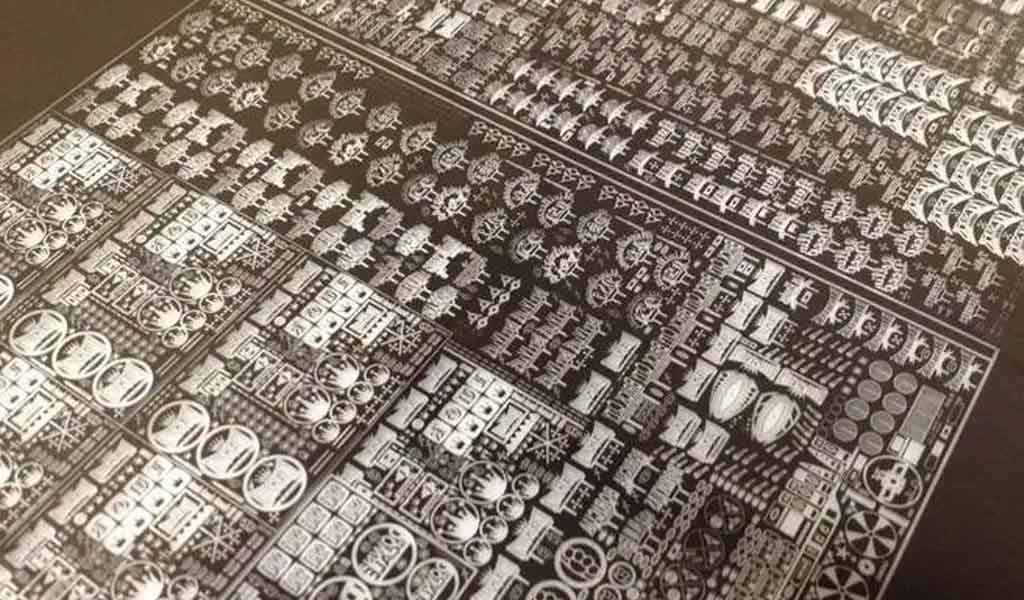

Precision and intricate designs

Etching allows for the creation of intricate and precise designs on the speaker mesh, which may be challenging to achieve with traditional manufacturing methods.

This precision is crucial for producing visually appealing and high-quality speaker meshes that can enhance the overall aesthetics of the vehicle interior.

Customization and branding

Etching provides the flexibility to customize speaker meshes according to specific design requirements and branding needs. Automotive manufacturers can incorporate their logos, brand names, or unique patterns into the speaker mesh, contributing to brand recognition and differentiation in the market.

Consistency and repeatability

Etching ensures consistent and repeatable results, enabling the mass production of speaker meshes with uniform designs and quality. This level of consistency is essential for meeting the high standards and specifications set by automotive manufacturers for their products.

Material preservation

Compared to other mechanical manufacturing processes, etching minimizes the risk of damaging the material properties of the metal used for the speaker mesh. It helps retain the structural integrity and strength of the metal while achieving the desired design, texture, or pattern, ensuring the durability and longevity of the speaker mesh.

Cost-effectiveness

In many cases, etching can be a cost-effective solution for producing automotive speaker meshes, especially when considering the benefits it offers in terms of design flexibility, precision, and repeatability. The ability to create complex designs without the need for extensive manual labor or specialized tooling can contribute to overall cost savings in the manufacturing process.

Through the etching process, the automotive metal horn mesh achieves the design requirements of high-precision manufacturing and effective control of its thickness and weight. This process not only improves the quality of the speaker mesh itself, but also has the advantages of environmental protection and efficient production. The automotive metal speaker mesh prepared by the etching process can effectively enhance the performance of the car audio system and reduce production costs, helping companies gain stronger market competitiveness. It can be said that the etching process has injected new vitality into the prosperity and development of the automotive industry. In the field of automobile manufacturing, metal mesh is an important component, and the choice of its manufacturing process has a crucial impact on the quality and performance of the product.

The application of etching technology provides new possibilities and broader development space for the manufacturing of automotive metal speaker mesh.

First of all, the high-precision characteristics of the etching process in the manufacturing process of the speaker mesh can not only significantly improve the accuracy of the speaker mesh, but also control the error range to a very small range, even within ±0.02mm. . Such high-precision products can not only meet strict automotive quality requirements, but also greatly improve the performance of car audio systems, providing drivers with clearer and more pleasant music enjoyment.

Secondly, the depth control advantage of the etching process provides the possibility of precise control of the thickness and weight of the metal speaker mesh. This precise control allows the speaker mesh to accurately meet the design requirements in terms of weight and thickness while meeting the strength requirements. This can not only improve the overall quality of the car, but also effectively reduce production costs and enhance the company’s market competitiveness.

Thirdly, the etching process also has the advantage of being environmentally friendly. In the manufacturing process of laer net, the etching process can reduce the generation of waste and pollution, and reduce the impact on the environment. This environmentally friendly feature not only conforms to the current society’s pursuit of sustainable development, but is also an inevitable choice for enterprises to achieve long-term development.

Finally, the etching process has high production efficiency, which can greatly shorten the production cycle and reduce production costs. At the same time, the etching process is highly automated, which can reduce labor input, reduce human errors, and improve production efficiency. This will undoubtedly save companies a lot of costs and improve market competitiveness.

By leveraging the etching process, automotive manufacturers can produce high-quality, visually appealing, and customized speaker meshes that meet the demanding requirements of the automotive industry in terms of both functionality and aesthetics.