Homepage » Metal Etching »

Electrochemical Etching

Electrochemical etching, also known as electrolytic etching or electrochemical machining, is a process that uses an electrochemical reaction to remove material from the surface of a metal or other conductive materials. This method is commonly used for marking, engraving, or etching designs, patterns, text, or other information onto the surface of materials. It offers several advantages, including high precision, the ability to etch complex and fine details, and the absence of mechanical forces that could deform or damage the workpiece.

However, it’s primarily suited for conductive materials and may not be suitable for non-metallic materials or non-conductive surfaces.

Electrochemical Etching Service & Manufacturer In China

BE-CU ETCH offering Electrochemical etching services for the aerospace, automotive, defense, decorative, electronic, medical, semiconductor, sensor, instrument, power generation and filtration industries. Works with stainless steel, steel, aluminum, beryllium copper, brass, bronze, ceramic, copper, exotic metals, Inconel®, Kovar®, molybdenum, nickel alloys and superalloy. Capable of etching parts from 0.001 in. to 0.006 in. depth. Prototype and low to high volume production runs are available.Other capabilities include electroforming and milling. Secondary services such as bending, coating, deburring, heat treating, plating, polishing, stamping, welding, assembly, cleaning, packaging, shipping and warehousing also provided.

Electrochemical Etching Parts

With our Electrochemical etching service, we can cater to both one-off prototypes and high-volume production requirements, enabling us to serve a diverse range of specialist component applications.

-

Stainless Steel 316L Etching Tea Strainer

-

Zinc Alloy Nameplate Etching For Bags Logo/Signs

-

Precision Etched Brass H62 Maple Leaf Bookmark

-

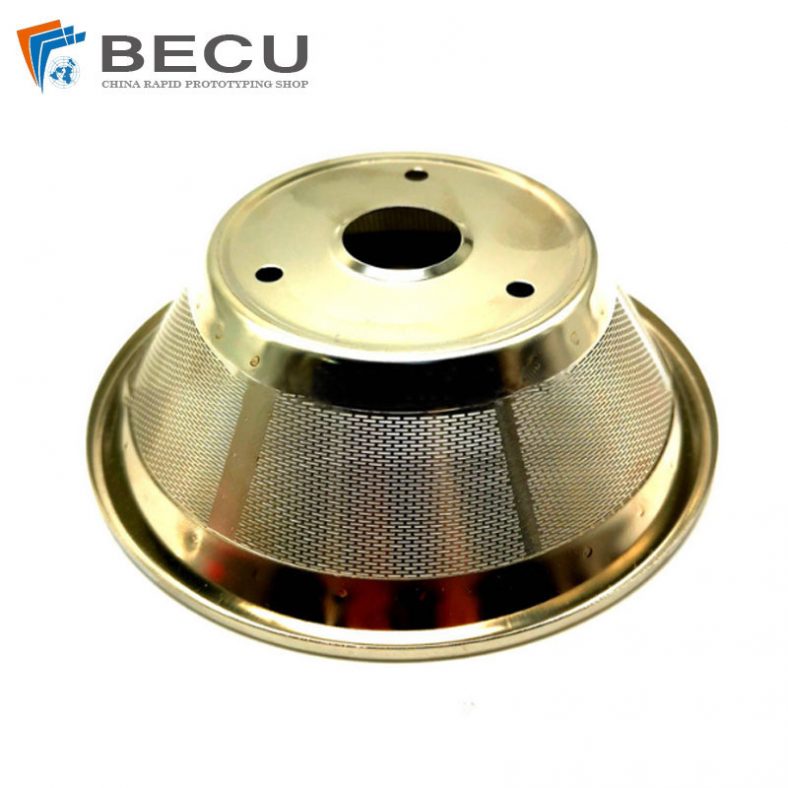

3D Etched Special-Shaped Stainless Steel 304 Spinning Lampshade

-

Painted Hollow Background Wall Brass Etching Decoration

-

Brass 360 Hollow Etched Hangtag

-

430 Stainless Steel Photoelectric Encoder Code Disc Etching

-

Stainless Steel 304 Wedge Filter Etching

-

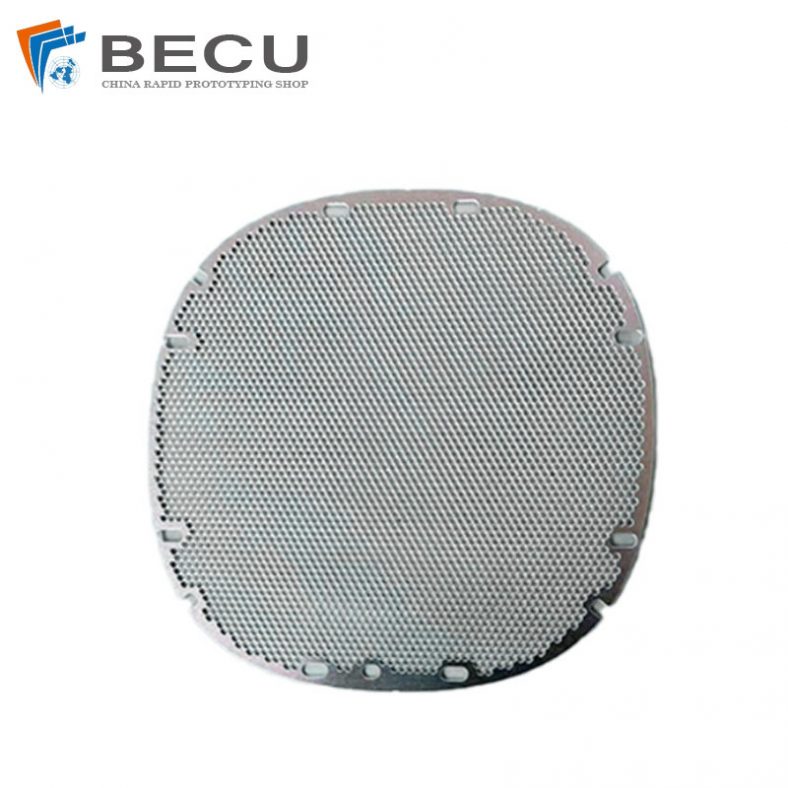

High Speed 316L Hair Dryer Mesh Etching

-

Aluminum Alloy 6061 Etched Bookmark

-

IC Lead Frame and VFD Dedicated Grid Etching

-

Metal Chemical Etching Reciprocating Razor Blades

Electrochemical Etching Type

Electrochemical etching is a process that uses an electrolyte and electrical current to remove material from a conductive surface to create a desired pattern or mark. There are several different types of electrochemical etching techniques, each with its own specific application and process. Some common types of electrochemical etching include:

- Electrolytic Etching: This is the most common form of electrochemical etching and is often used for marking or labeling metal surfaces. It involves creating a stencil or mask of the desired design, placing it on the metal surface, and then passing an electric current through the stencil and into the electrolyte to etch the metal. The metal dissolves in the areas exposed to the electrical current, leaving behind the etched pattern.

- Electrochemical Machining (ECM): ECM is a precision machining process that uses electrochemical principles to remove material from a workpiece. It is commonly used for high-precision machining of complex shapes in materials like metals and alloys. ECM uses a tool and a conductive electrolyte to remove material, and the tool shape can be controlled to create intricate shapes.

- Electrochemical Grinding (ECG): ECG is a variation of ECM that combines electrochemical action with conventional grinding. It is used to shape and finish hard materials, such as tungsten carbide and high-strength alloy steels, with high precision and minimal heat generation.

- Electrochemical Polishing: This process uses electrochemical principles to smooth and improve the surface finish of metals. It removes a very thin layer of material to create a highly polished surface.

- Electrochemical Deburring: Electrochemical deburring is used to remove sharp edges and burrs from machined metal parts. It is a precise method for removing burrs without altering the dimensions of the workpiece.

- Electrochemical Milling: Similar to ECM, electrochemical milling is used to create complex and intricate shapes in conductive materials by removing material via electrochemical dissolution.

- Electrochemical Discharge Machining (ECDM): ECDM is a hybrid process that combines aspects of electrochemical machining with electrical discharge machining (EDM) to shape and machine conductive materials. It is often used for advanced applications requiring high precision.

Each of these electrochemical etching methods has specific advantages and limitations, making them suitable for different applications in various industries, such as manufacturing, aerospace, and electronics. The choice of the appropriate technique depends on the material to be etched, the desired precision, and the specific requirements of the project.

Online Cooperate With Electrochemical Etching Company

We are not resellers of other companies’ parts.That’s because we enjoy making a living by producing, not by earning commissions on other people’s work. We are a true Electrochemical Etching service.

Your confidential files won’t be shared with third parties.

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision Electrochemical Etching on the planet. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.

Metal Etching Certification,Equipment List and Quality

We are committed to enlisting the full support of all employees to continuously improve our processes and enhance quality, thereby fulfilling our customer's needs with defect free products and services, on time and every time

- ISO 9001:2015 certified

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process FMEA

- Fully compliant with the exacting requirements of our customers

- ITAR registered

- NIST cybersecurity standard compliant

- Proprietary Patented quality systems

- Skilled in KanBan and other customer driven quality and inventory management systems

Metal Etching Material

BE-CU is experienced in precision etching various metals, allowing customers the freedom to specify components in hundreds of different materials.

The Surface Treatment Of Metal Etching Parts

Do you want your etching parts to be more corrosion-resistant or get a specific look? Metal finishing service is a essential choice to achieve your design perfectly. BE-CU – metal-etch.com is an accomplished finished parts manufacturer, our workers and craftsman are capable to provide precision metal etching services and a wide range of finishing services including aluminum anodizing, painting, passivation, electroplating, powder coating, polishing, black oxide, conversion coating, abrasive blasting, etc. We offers several common surface finishes to help improve functionality and aesthetics.

- Anodizing (Anodized)

- Passivation

- Plating (Electroplating)

- Painting

- Black Oxide (Hot Blackening)

- Polishing

- Powder Coating

- Heat Treatment

- Satin Finish

- Abrasive blasting (Sandblasting)

- Conversion coating

- Tungsten carbide coating

After browsing a list of metal finishing services, select a process based on essential considerations, like production time, cost-effectiveness, part tolerance, durability and applications. High-tolerance metal etching parts are not recommended to apply secondary metal surface finish, because the treatment may change the sizes of the finished part through removing or adding a small amount of materials.

Other requirements or custom designs, welcome to contact us for a free quote fast!