Homepage » Metal Etching »

Precision Etching Invar Alloy – Invar Etching

Invar etching is a specialized process utilized in the fabrication and modification of Invar, a nickel-iron alloy known for its unique thermal expansion properties. The term “Invar” is derived from “invariable,” reflecting the material’s minimal expansion or contraction with temperature changes. This property makes Invar essential in applications requiring high dimensional stability. Invar etching involves precision techniques to create detailed patterns and structures on Invar surfaces, serving various industries such as aerospace, electronics, and precision instruments.

Invar, typically composed of 64% iron and 36% nickel, exhibits an exceptionally low coefficient of thermal expansion (CTE) around room temperature. This property, along with its good mechanical properties, makes it ideal for applications where dimensional stability is crucial. Invar’s other notable properties include:

- Low Thermal Expansion: Invar’s CTE is close to zero at ambient temperatures, making it resistant to dimensional changes with temperature fluctuations.

- Good Mechanical Strength: It maintains good tensile strength and hardness, making it suitable for structural applications.

- Magnetic Properties: Invar is ferromagnetic, which can be both a benefit and a drawback, depending on the application.

- Corrosion Resistance: It exhibits moderate resistance to corrosion, which can be enhanced through protective coatings.

BE-CU specializes in delivering precision invar etching solutions across various industries, including electronics, automotive, aerospace, and medical devices. Our state-of-the-art technology enables us to produce highly detailed, complex designs with unparalleled accuracy and consistency. We pride ourselves on our ability to work with a wide range of invar alloy, offering custom etching services tailored to our clients’ specific requirements. Our commitment to quality, innovation, and customer service has established us as a leader in the metal etching sector. With a focus on rapid turnaround times and competitive pricing, we are dedicated to exceeding our clients’ expectations and driving their success.

Our Invar Etching Service

With over 30 years of experience manufacturing Invar parts, BE-CU ETCH Company offers a truly unparalleled level of expertise in custom Invar etching. We work with both free machining and Naval invar and offer numerous plating options, including electroless nickel plating, which adds a less porous, all-enveloping barrier to etching invar parts for superior corrosion resistance. All of our precision etching operations adhere to strict quality standards, and our company is ISO 9001:2015-certified.

At BE-CU ETCH, we are proud to offer precision invar etching services for industries such as aerospace, medical, industrial, and defense. Our extensive knowledge and experience in etching invar parts allow us to deliver quality parts with tight tolerances. Our modern facility is equipped with a wide range of etching equipments to meet your unique requirements with precision and speed. To learn more about our invar etching services, contact us or request a quote today.

Our Etching Capabilities

- Etching of many grades of invar alloys

- Combining Stamping, Laser Cutting,CNC machining and photochemical etching on sheets up to 2mm thick

- Etching of up to 0.025″ thick sheets as large as 22×12 inches

- Tolerances of ±.0005″ in many applications

How To Etch Invar

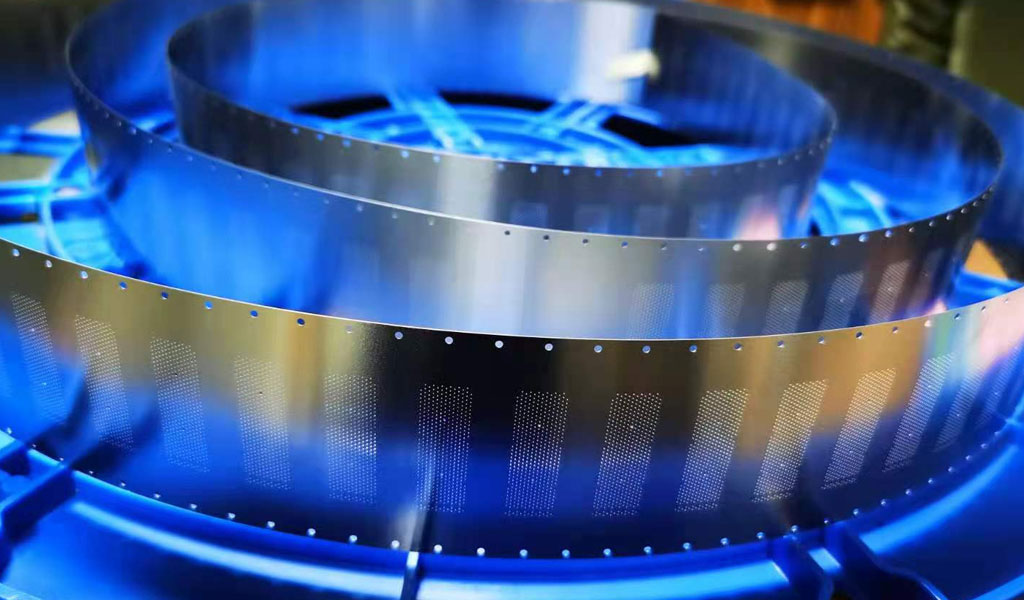

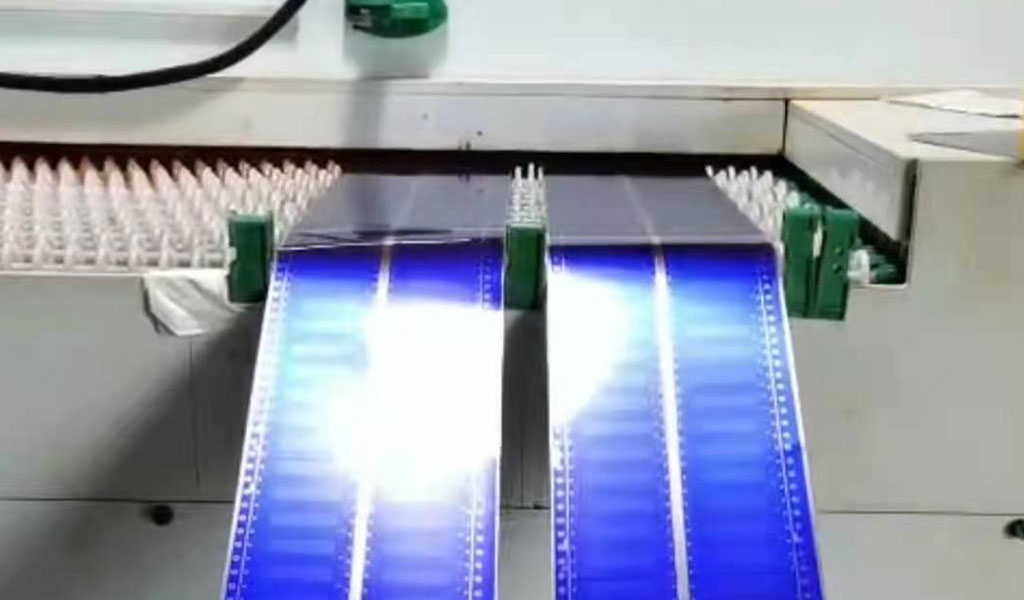

Automated-Coating

Automatic-Baking-Line

Automatic-Shearing

Coating-For-Etching-Parts

Deinking

Etching

Exposure

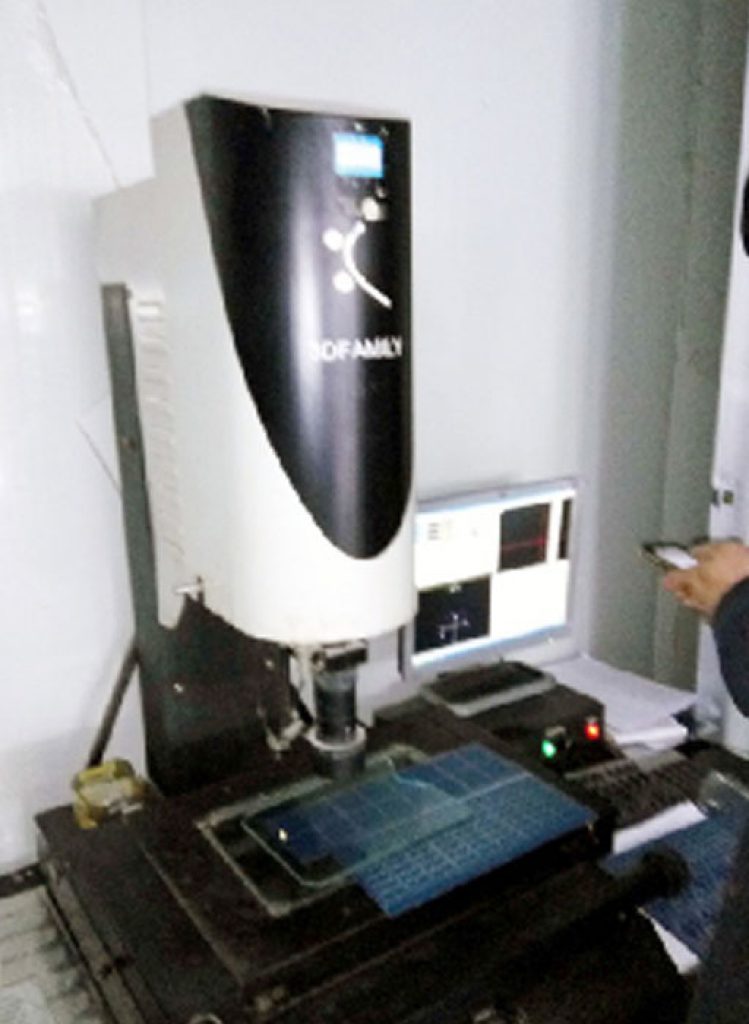

Inspection-For-Etching

Metal Grades For Invar Etching

Invar, a nickel-iron alloy, is renowned for its exceptionally low coefficient of thermal expansion (CTE), making it an essential material for applications requiring high dimensional stability. However, not all Invar alloys are the same; they come in different grades tailored for specific applications and processes, including etching. Understanding the different grades of Invar and their properties is crucial for selecting the right material for etching purposes.

The most common grade of Invar is the standard Invar 36, which contains 36% nickel and 64% iron. This grade is the benchmark for most applications requiring low thermal expansion. However, several other grades have been developed to meet specific needs.

Invar 36 (UNS K93600)

Properties: The standard grade with a low CTE around room temperature, good mechanical strength, and moderate corrosion resistance.

Applications: Used in aerospace, electronics, and precision instruments where dimensional stability is crucial.

Invar 42 (UNS K94100)

Properties: Slightly higher CTE than Invar 36 but still low compared to other metals. It offers better machinability and weldability.

Applications: Often used in electronic packaging and components, where a slightly higher CTE can be tolerated.

Super Invar (UNS K93050)

Properties: Exhibits an even lower CTE than Invar 36, particularly at cryogenic temperatures, along with good stability and strength.

Applications: Used in applications requiring extremely low thermal expansion, such as scientific instruments and optical devices.

Kovar (UNS K94610)

Properties: Similar thermal expansion to borosilicate glass, making it ideal for glass-to-metal seals. It also has good mechanical properties and thermal stability.

Applications: Widely used in electronic and semiconductor industries for glass-to-metal seals and hermetic packages.

Selecting the appropriate grade of Invar for etching is critical to achieving the desired performance and reliability in precision applications. Each Invar grade offers unique properties that influence its suitability for specific etching processes and end-use applications. Advances in etching techniques and materials science continue to expand the capabilities and applications of Invar, ensuring its relevance in high-precision industries. Understanding the nuances of each Invar grade and the corresponding etching processes is essential for leveraging this versatile material to its full potential.

Components That Are Produced By Etching Invar

The popularity of invar makes it a desirable metal for use in fabrication because it is easy to manufacture and has favorable properties for many industrial products.With the photo etching process, the metal is etched evenly without any structural deformations from the hard tooling used in stamping and punching.Since there isn’t a heat point of contact like laser cutting, the parts’ metal properties remain unchanged and free from thermal deformations.Get inspired by our custom etching part projects and contact us to Get Instant Quote for rapid prototype or Invar etching parts start from 1pcs.

Metal Etching Certification,Equipment List and Quality

We are committed to enlisting the full support of all employees to continuously improve our processes and enhance quality, thereby fulfilling our customer's needs with defect free products and services, on time and every time

- ISO 9001:2015 certified

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process FMEA

- Fully compliant with the exacting requirements of our customers

- ITAR registered

- NIST cybersecurity standard compliant

- Proprietary Patented quality systems

- Skilled in KanBan and other customer driven quality and inventory management systems

Metal Etching Material

BE-CU is experienced in precision etching various metals, allowing customers the freedom to specify components in hundreds of different materials.

The Surface Treatment Of Metal Etching Parts

Do you want your etching parts to be more corrosion-resistant or get a specific look? Metal finishing service is a essential choice to achieve your design perfectly. BE-CU – metal-etch.com is an accomplished finished parts manufacturer, our workers and craftsman are capable to provide precision metal etching services and a wide range of finishing services including aluminum anodizing, painting, passivation, electroplating, powder coating, polishing, black oxide, conversion coating, abrasive blasting, etc. We offers several common surface finishes to help improve functionality and aesthetics.

- Anodizing (Anodized)

- Passivation

- Plating (Electroplating)

- Painting

- Black Oxide (Hot Blackening)

- Polishing

- Powder Coating

- Heat Treatment

- Satin Finish

- Abrasive blasting (Sandblasting)

- Conversion coating

- Tungsten carbide coating

After browsing a list of metal finishing services, select a process based on essential considerations, like production time, cost-effectiveness, part tolerance, durability and applications. High-tolerance metal etching parts are not recommended to apply secondary metal surface finish, because the treatment may change the sizes of the finished part through removing or adding a small amount of materials.

Other requirements or custom designs, welcome to contact us for a free quote fast!