Homepage » Metal Etching »

What Is Laser Etching

Laser etching is a process that uses a laser beam to create marks on a surface, by emitting large amounts of energy for a specific period of time. Can be used for a variety of applications including engraving and cutting.

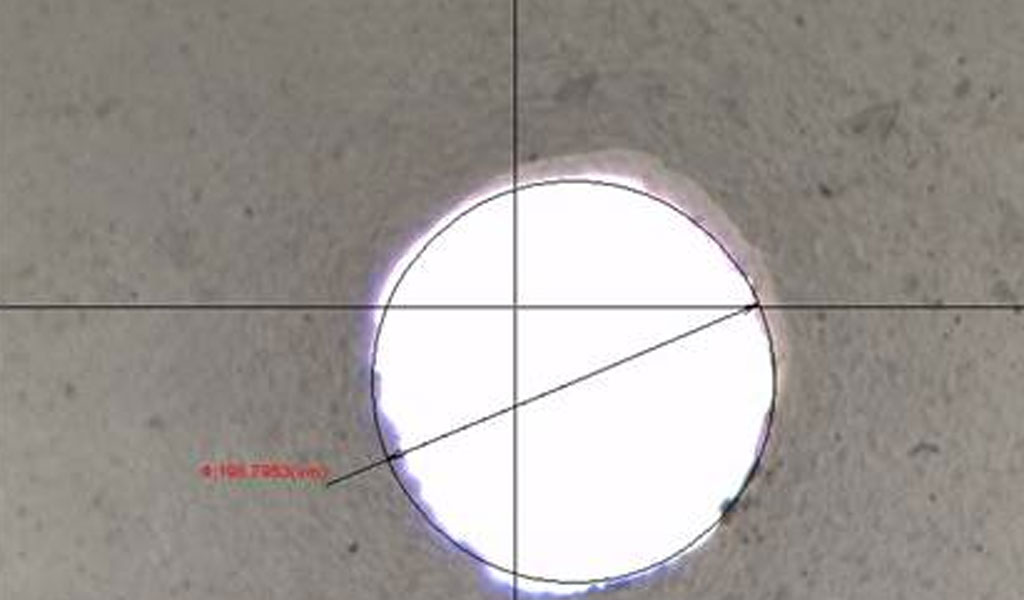

During the laser etching process, the extremely high temperature of the laser beam melts the metal surface upon contact. When melted, the molten material expands, leaving marks on the surface of the material.

How To Laser Etching – Laser Etching Process

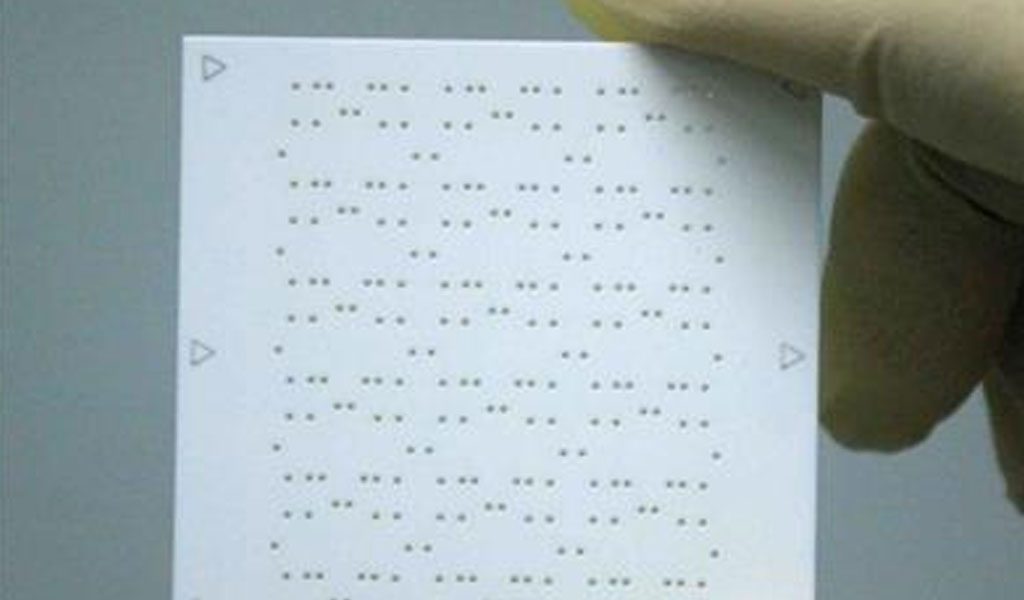

Laser etched designs are generated by graphic design software. This graphic design software supports vector files. Once the design is complete, save it as a vector file and transfer it to a laser etching machine for printing. The laser etcher reads out the vector file using a CNC router. It also determines the pattern of laser movement and creates the desired design.

The whole purpose of anodizing aluminum is to convert the surface layer of aluminum into aluminum oxide. This material is more resistant to corrosion and wear than the pure aluminum hiding beneath it.

Although aluminum oxide is actually transparent, some anodization methods produce porous aluminum oxide layers that can be colored with special dyes. Therefore, anodized aluminum is more durable than regular aluminum and will not corrode, scratch, or break. And it comes in a lot of colors to choose from – a lot of advantages

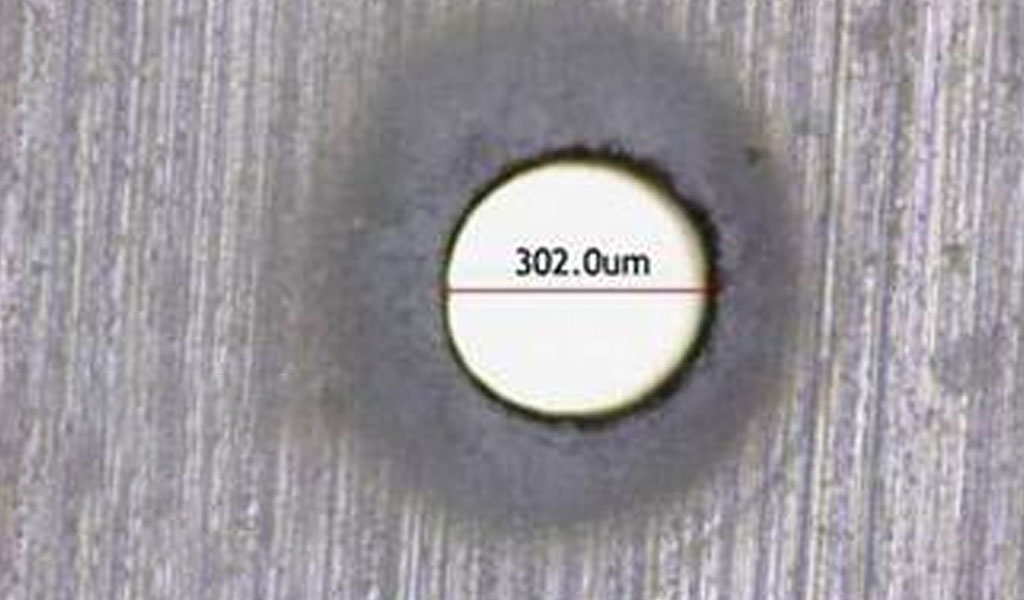

The anodizing process only affects the surface of the aluminum to a depth of 0.1-1.0 mm. This makes the laser etching process, with an impact depth of only 0.25 mm, the best choice for marking anodized aluminum. By comparison, laser engraving has an impact depth of 3mm, which means the laser exposes less durable aluminum beneath the anode layer, making the item more susceptible to damage.

Laser etching and engraving technology is used across a wide range of industries to mark stamps, lettermarks and barcodes. Their techniques are similar, but there are differences.

The main difference between laser etching and engraving processes is the depth of cut. Laser engraving penetrates the entire aluminum material, while laser etching is a shallow cut that only cuts part of the material.

Laser etching is typically used on anodized aluminum because it does not remove the anodized layer. This program can be used for serial numbers, barcodes, or other graphics that need to be displayed but not dark.

China Top Laser Etching Parts Suppliers & Manufacturer

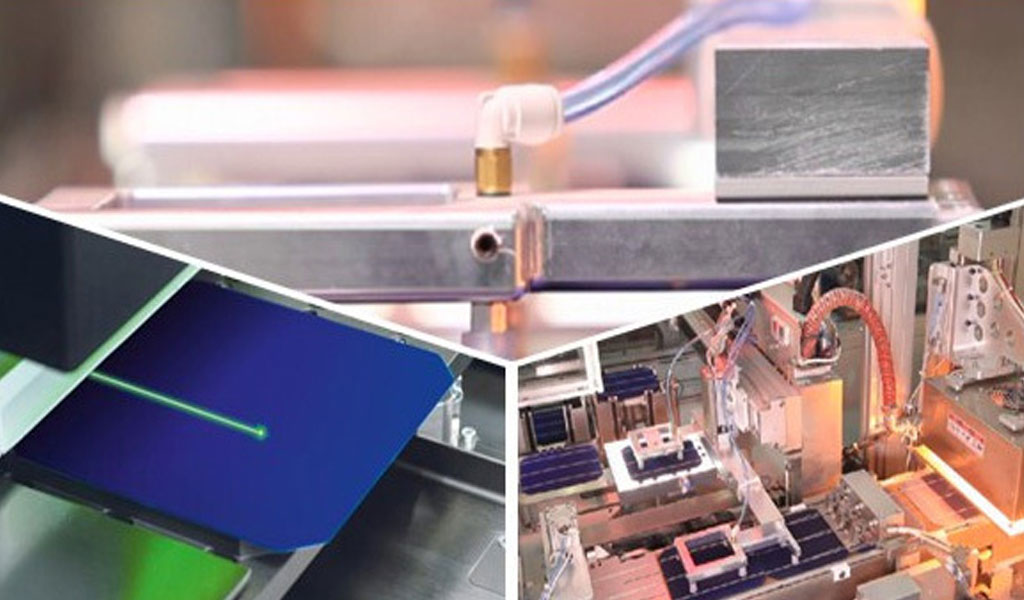

Compared with traditional wet etching, laser etching does not directly contact the material surface, CAD drawings are written directly, and no mask is required. Therefore, it is more reliable, has higher yield, better consistency, adjustable etching line width and arbitrary graphics. , this technology has been widely used in industrial production such as touch screens, LCDs, PDPs, e-books, and OLEDs. In other application fields, especially the selective etching of some higher-demand multi-layer materials, other traditional methods cannot achieve it.

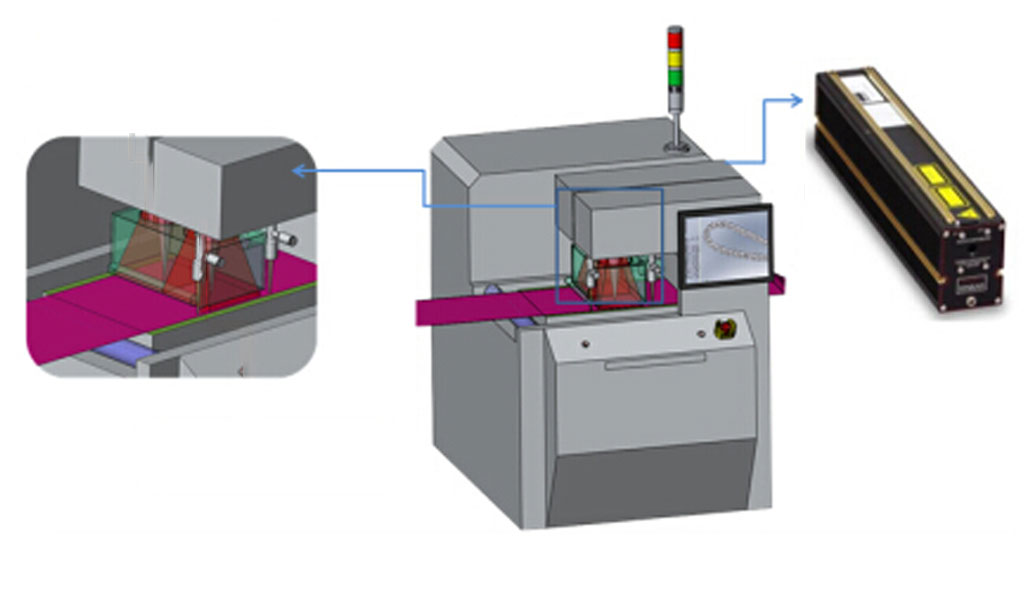

Be-Cu ETCH is a high-tech enterprise that relies on international advanced laser technology and is committed to the research, development and OEM of laser precision processing. We have more than 1,000 square meters of Class 10,000 clean laboratories and production workshops, an experienced technical development and management team, and more than 20 advanced imported laser sources including ultraviolet lasers, ultrafast lasers, fiber lasers, carbon dioxide lasers, etc. As well as supporting processing platforms, the company also has detection and analysis tools including 3D microscopes, laser interferometers, infrared thermal imaging cameras, and two-dimensional dimensions.

Be-Cu ETCH focuses on micron-level laser precision cutting, drilling, etching, engraving, dicing, material removal, structure, engraving and marking of special materials. It is mainly used in LED chip manufacturing, touch screens, LCDs, consumer products Electronics, semiconductors, MEMS, lighting, medical and other industries, as well as scientific research, aerospace, military and other fields, involving various materials including various metals and alloys, semiconductors, ceramics, various transparent materials, films and polymers, the company has He has conducted more than 1,000 various laser micromachining experiments and solutions based on the above materials.To learn more about our laser etching services, contact us or request a quote today.

Durable, High-Precision Laser Etching Material

Because different lasers have different types, wavelengths, pulse widths, frequencies, powers and other parameters, as well as working environments, their interactions with materials will also be different. Therefore, a specific laser has certain selectivity for materials. In the world There is no universal laser that can handle all processing tasks; fortunately, BE-CU ETCH’s hardware investment covers almost all laser series suitable for precision micromachining, especially multiple ultra-fast lasers with “cold processing” technology , so we are never picky about any material.

Metal Etching Certification,Equipment List and Quality

We are committed to enlisting the full support of all employees to continuously improve our processes and enhance quality, thereby fulfilling our customer's needs with defect free products and services, on time and every time

- ISO 9001:2015 certified

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process FMEA

- Fully compliant with the exacting requirements of our customers

- ITAR registered

- NIST cybersecurity standard compliant

- Proprietary Patented quality systems

- Skilled in KanBan and other customer driven quality and inventory management systems

Metal Etching Material

BE-CU is experienced in precision etching various metals, allowing customers the freedom to specify components in hundreds of different materials.

The Surface Treatment Of Metal Etching Parts

Do you want your etching parts to be more corrosion-resistant or get a specific look? Metal finishing service is a essential choice to achieve your design perfectly. BE-CU – metal-etch.com is an accomplished finished parts manufacturer, our workers and craftsman are capable to provide precision metal etching services and a wide range of finishing services including aluminum anodizing, painting, passivation, electroplating, powder coating, polishing, black oxide, conversion coating, abrasive blasting, etc. We offers several common surface finishes to help improve functionality and aesthetics.

- Anodizing (Anodized)

- Passivation

- Plating (Electroplating)

- Painting

- Black Oxide (Hot Blackening)

- Polishing

- Powder Coating

- Heat Treatment

- Satin Finish

- Abrasive blasting (Sandblasting)

- Conversion coating

- Tungsten carbide coating

After browsing a list of metal finishing services, select a process based on essential considerations, like production time, cost-effectiveness, part tolerance, durability and applications. High-tolerance metal etching parts are not recommended to apply secondary metal surface finish, because the treatment may change the sizes of the finished part through removing or adding a small amount of materials.

Other requirements or custom designs, welcome to contact us for a free quote fast!