Homepage » Metal Etching »

Medical Etching – Metal Etching for Medical Industries

Medical etching is a specialized process that involves the precise removal of material from medical devices, instruments, and implants to achieve desired surface characteristics and features. This technique is critical in the medical field, as it enhances the functionality, biocompatibility, and aesthetic qualities of various devices used in healthcare.

Medical etching is defined as the process of selectively removing material from a substrate using chemical or physical means to create patterns, textures, or functional surfaces. The primary purpose of etching in medical applications includes:

- Enhancing the biocompatibility of implants

- Increasing the surface area for improved bonding with biological tissues

- Creating features for microfluidic devices

- Achieving specific aesthetic finishes

Medical etching is a vital process that significantly enhances the functionality and performance of medical devices. Through the application of various etching techniques on a range of materials, manufacturers can create devices that meet the stringent demands of the healthcare industry. As technology advances and regulatory standards evolve, medical etching will continue to play a crucial role in the development of innovative medical solutions.

Our Medical Etching Service

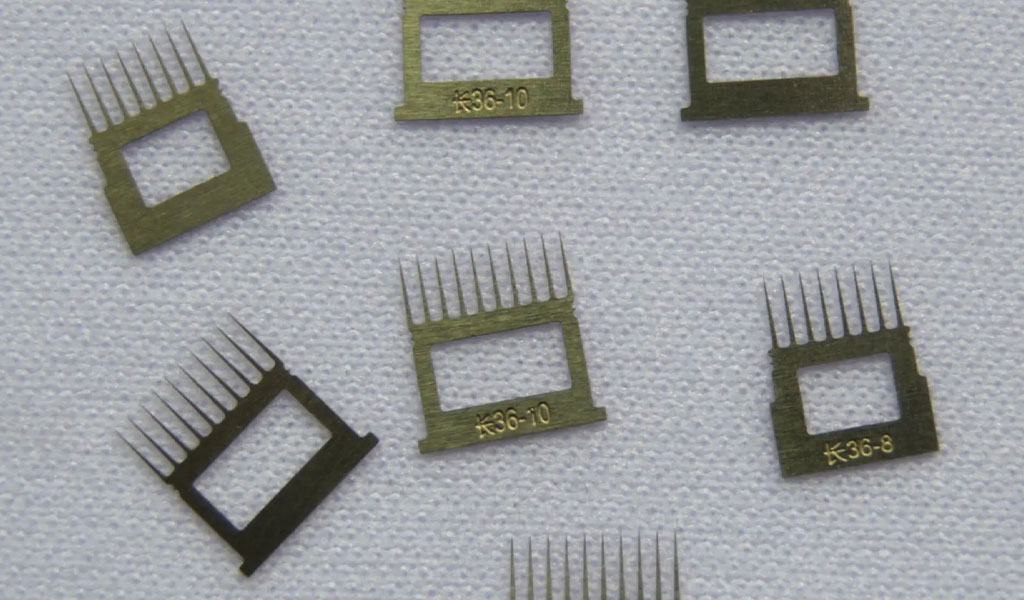

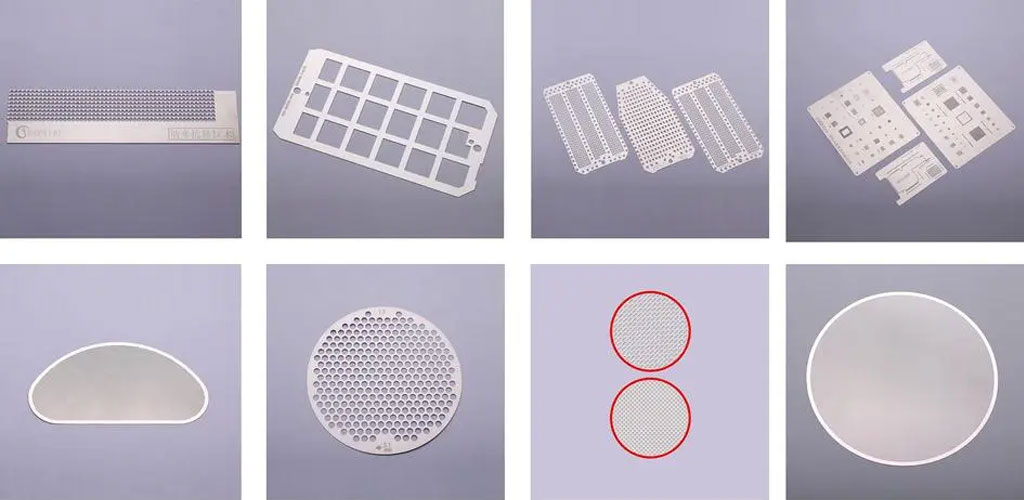

If you need medical parts etched we are one of the most capable and affordable sources specializing in manufacturing custom etched parts on advanced photo etching machines with cnc precision. Through our Photo Chemical Etching process, the smallest and most complex designs are made possible such as electrical spring contacts, contact membranes, busbars, antennae and micro antennae, spring fingered contacts, heating elements and battery terminal as well as many other bespoke components to your own designs.

We can machine to print and accept the most common file formats including: .dwg .dxf .iges .step .sat as well as .pdf files. If you don’t see your file format here let us know. Please send us files to: [email protected] We can accept both small and large run jobs of custom medical etching parts.

Our Etching Capabilities

- Etching of many grades of metal and more

- Combining Stamping, Laser Cutting,CNC machining and photochemical etching on sheets up to 2mm thick

- Etching of up to 0.025″ thick sheets as large as 22×12 inches

- Tolerances of ±.0005″ in many applications

How To Etch Medical Parts

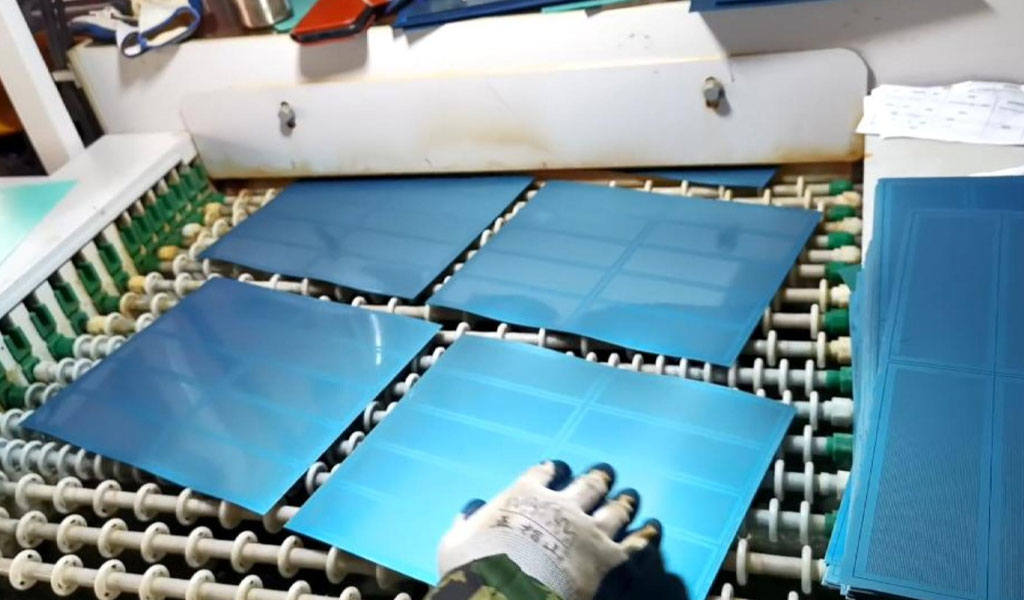

Automated-Coating

Automatic-Baking-Line

Automatic-Shearing

Coating-For-Etching-Parts

Deinking

Etching

Exposure

Inspection-For-Etching

Flexible Used Of Medical Etching Technology

In the field of medicine, etching technology plays a pivotal role in the fabrication of microstructures, biosensors, and microfluidic chips, among other applications. The following outlines some of the significant uses of etching within the medical domain:

- Microstructure Fabrication: Etching techniques enable the creation of micro-scale structures such as microchannels, microarrays, micropillars, and micropores. These structures serve as essential components in the development of microfluidic chips, microdevices, and microelectrode arrays, facilitating advancements in medical diagnostics, drug delivery, and tissue engineering.

- Biosensor Development: Through etching technology, microelectrodes and biosensor arrays can be fabricated with specific shapes and dimensions, allowing for the detection of biomolecules, cells, and proteins. This capability is extensively utilized in biomedical testing, biosensing, and bioimaging applications.

- Neural Stimulation Devices: Etching techniques are employed to produce microelectrode arrays designed for neural stimulation and signal recording. These devices are integral to neuroscientific research, brain-machine interface technologies, and neuromodulation therapies.

- Microfluidic Chips: The precision of etching allows for the construction of micro-sized channels and structures that form miniature fluidic systems. These systems are utilized in applications such as microreactors, drug screening, cell culture, and bioanalysis.

- Medical Instrument Fabrication: Etching technology is instrumental in the development of miniature medical instruments, including microneedles, micro syringes, and microdetectors. These devices are critical for minimally invasive surgeries, drug delivery, and tissue sampling in medical applications.

Overall, etching technology encompasses a wide range of applications in the medical field, including biomedical testing, biosensing, microfluidic systems, neuroscience research, and minimally invasive medical procedures. It provides vital technological support for both medical research and clinical treatments, advancing the frontiers of healthcare innovation.

Components That Are Produced By Etching Medical Parts

The popularity of medical makes it a desirable metal for use in fabrication because it is easy to manufacture and has favorable properties for many industrial products.With the photo etching process, the metal is etched evenly without any structural deformations from the hard tooling used in stamping and punching.Since there isn’t a heat point of contact like laser cutting, the parts’ metal properties remain unchanged and free from thermal deformations.Get inspired by our custom etching part projects and contact us to Get Instant Quote for rapid prototype or medical etching parts start from 1pcs.

Metal Etching Certification,Equipment List and Quality

We are committed to enlisting the full support of all employees to continuously improve our processes and enhance quality, thereby fulfilling our customer's needs with defect free products and services, on time and every time

- ISO 9001:2015 certified

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process FMEA

- Fully compliant with the exacting requirements of our customers

- ITAR registered

- NIST cybersecurity standard compliant

- Proprietary Patented quality systems

- Skilled in KanBan and other customer driven quality and inventory management systems

Metal Etching Material

BE-CU is experienced in precision etching various metals, allowing customers the freedom to specify components in hundreds of different materials.

The Surface Treatment Of Metal Etching Parts

Do you want your etching parts to be more corrosion-resistant or get a specific look? Metal finishing service is a essential choice to achieve your design perfectly. BE-CU – metal-etch.com is an accomplished finished parts manufacturer, our workers and craftsman are capable to provide precision metal etching services and a wide range of finishing services including aluminum anodizing, painting, passivation, electroplating, powder coating, polishing, black oxide, conversion coating, abrasive blasting, etc. We offers several common surface finishes to help improve functionality and aesthetics.

- Anodizing (Anodized)

- Passivation

- Plating (Electroplating)

- Painting

- Black Oxide (Hot Blackening)

- Polishing

- Powder Coating

- Heat Treatment

- Satin Finish

- Abrasive blasting (Sandblasting)

- Conversion coating

- Tungsten carbide coating

After browsing a list of metal finishing services, select a process based on essential considerations, like production time, cost-effectiveness, part tolerance, durability and applications. High-tolerance metal etching parts are not recommended to apply secondary metal surface finish, because the treatment may change the sizes of the finished part through removing or adding a small amount of materials.

Other requirements or custom designs, welcome to contact us for a free quote fast!