Homepage » Metal Etching »

Monel Etching

Monel is a group of nickel alloys, primarily composed of nickel (up to 67%) and copper, with small amounts of iron, manganese, carbon, and silicon. Known for its remarkable resistance to corrosion and acids, Monel is utilized in various industries, including marine engineering, chemical and hydrocarbon processing equipment, valves, pumps, and piping systems. The process of etching Monel involves the use of chemicals to remove layers of material to create a specific design or pattern.

This technique is highly valued in manufacturing and artistic fields due to Monel’s durability and resistance properties.Monel was first developed in the early 20th century by the International Nickel Company (INCO). Named after company president Ambrose Monell, the alloy quickly gained popularity due to its superior corrosion resistance and mechanical properties. It was initially used in applications where strength and durability were paramount, such as in the production of aircraft and military equipment.

The etching of metals has a long history, with techniques evolving significantly over time. The application of etching to Monel began in earnest as industries recognized the need for precise and durable patterns and designs on this robust material. Early etching methods involved simple acid treatments, but as technology advanced, more sophisticated and controlled etching processes were developed.

Top-Grade Monel Etching Service – Cost-Effective Monel Etching Parts

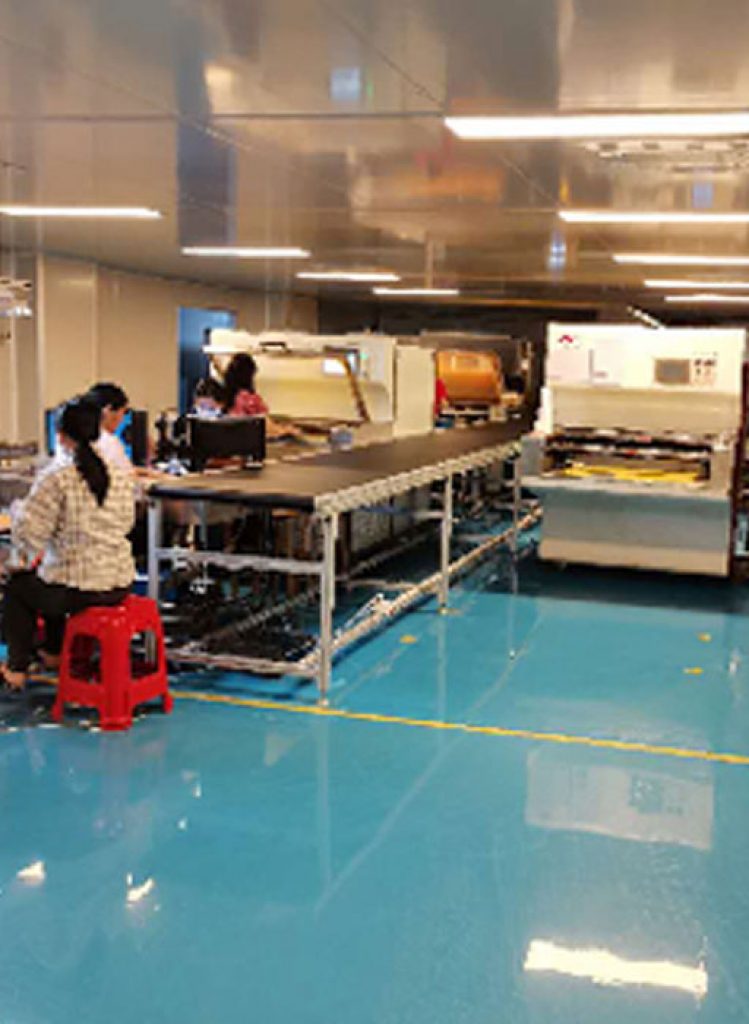

Looking for reliable, quick-turn Monel Etching services suppliers and metal etching product manufacturers? With advanced chemical etching and acid etching production line, our unparalleled design and production capacity capabilities guarantee premier OEM Monel Etching Parts to worldwide customers. At BE-CU – China Top Metal Etching Supplier, you can find comprehensive certified chemical etching process in Monel materials for rapid prototyping and low-volume production of end-use components or full item.

Our Etching Capabilities

- Etching of many grades of Monel, including 4J29,ASTM F-15, NILO K, Pernifer 2918,Dilver P-153

- Combining Stamping, Laser Cutting,CNC machining and photochemical etching on sheets up to 2mm thick

- Etching of up to 0.025″ thick sheets as large as 22×12 inches

- Tolerances of ±.0005″ in many applications

Properties of Etching Monel

Monel etching is a highly specialized process that leverages the unique properties of Monel alloys to create durable, precise, and corrosion-resistant components. From industrial applications to artistic creations, the versatility and durability of etched Monel continue to make it a valuable material in various fields. As technology advances, the potential for new applications and improved processes promises to further enhance the role of Monel etching in the future.

Chemical Composition

Monel alloys typically contain:

- Nickel: 63-70%

- Copper: 20-29%

- Iron: 2.5%

- Manganese: 2%

- Other elements: less than 1%

Mechanical Properties

Monel is known for its excellent mechanical properties, including:

- High tensile strength

- Good ductility

- Low coefficient of thermal expansion

- High resistance to various corrosive environments

Metal Grades For Monel Etching

Monel alloys, known for their exceptional corrosion resistance and mechanical properties, come in various grades to suit different applications. When it comes to etching, selecting the appropriate grade of Monel is crucial to achieving the desired results. Each grade has unique properties that can affect the etching process and the performance of the final product. This section explores the different grades of Monel used for etching, their composition, properties, and specific applications.Monel alloys are categorized into several grades, each with distinct characteristics. The most commonly used grades for etching include:

Monel 400

Monel K-500

Monel R-405

How To Etch Monel

Automated-Coating

Automatic-Baking-Line

Automatic-Shearing

Coating-For-Etching-Parts

Deinking

Etching

Exposure

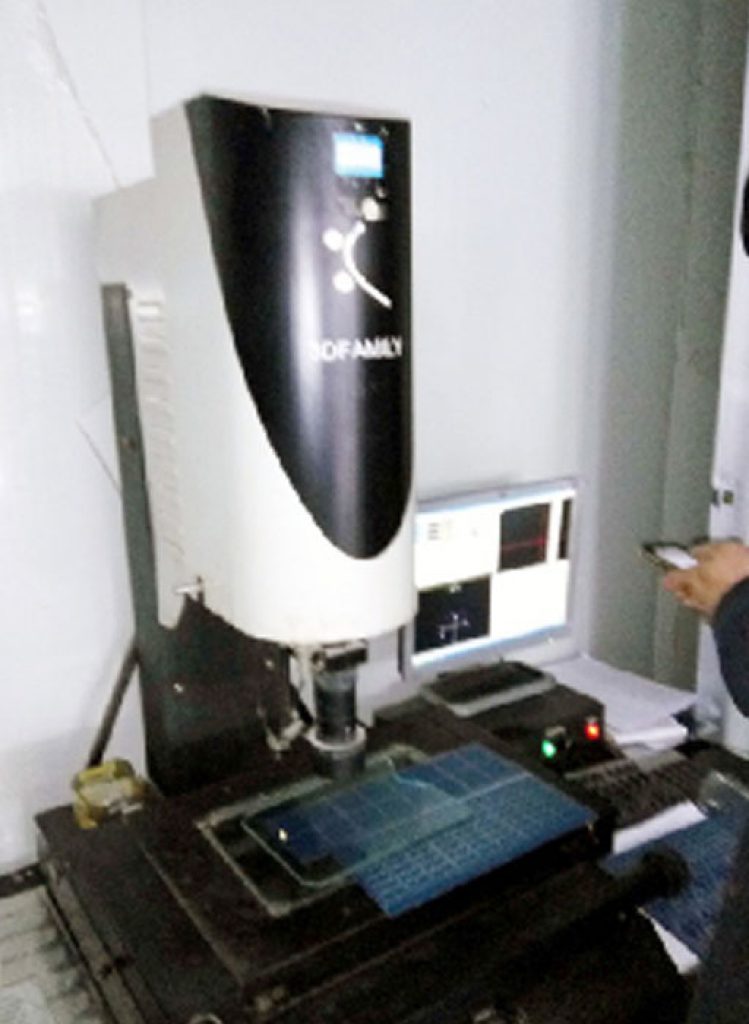

Inspection-For-Etching

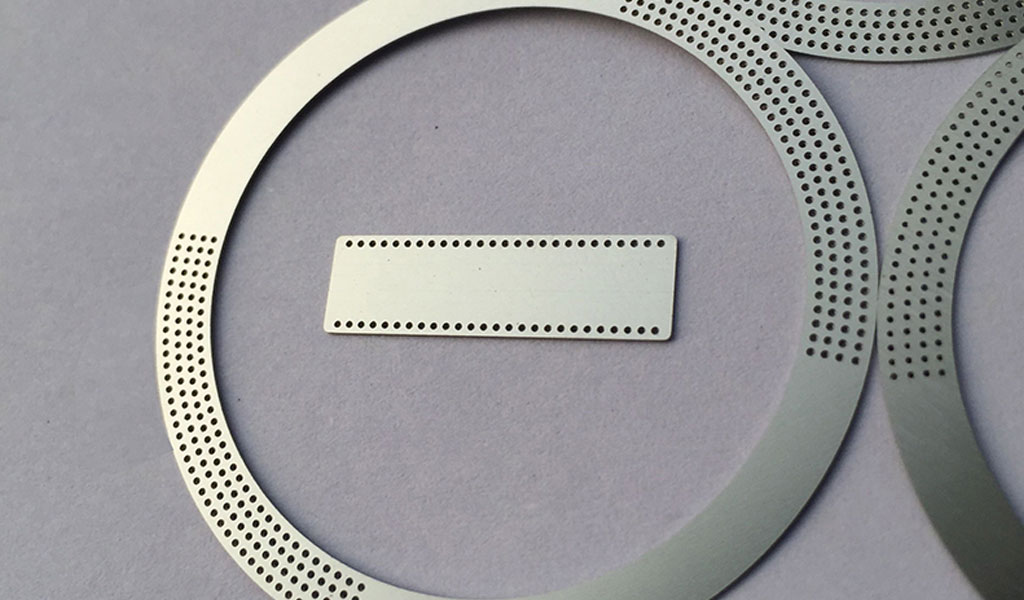

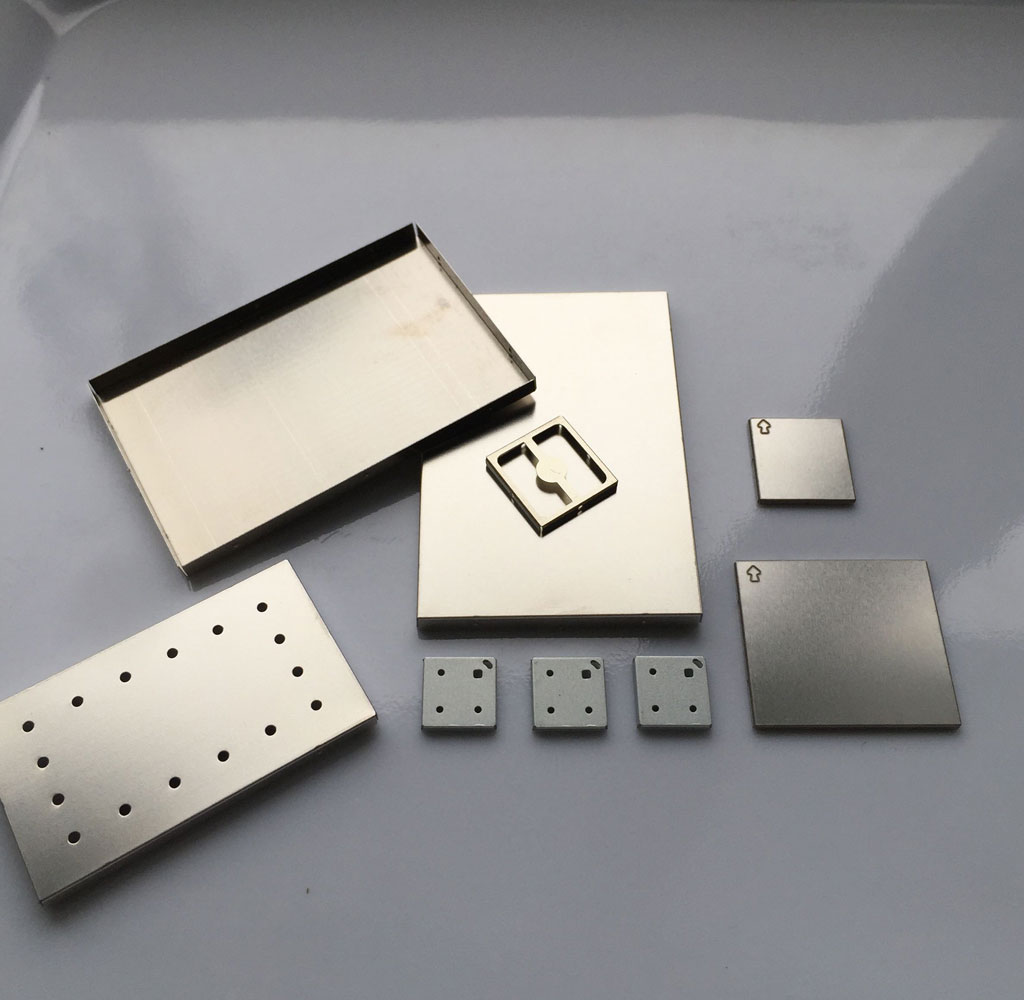

Components That Are Produced By Etching Monel

The popularity of monel makes it a desirable metal for use in fabrication because it is easy to manufacture and has favorable properties for many industrial products.With the photo etching process, the metal is etched evenly without any structural deformations from the hard tooling used in stamping and punching.Since there isn’t a heat point of contact like laser cutting, the parts’ metal properties remain unchanged and free from thermal deformations.Get inspired by our custom etching part projects and contact us to Get Instant Quote for rapid prototype or monel etching parts start from 1pcs.

-

Copperplate Engravings Of World Famous Works

-

Artistic Etched Copper Shielding Electronics Playing Cards with Patterns

-

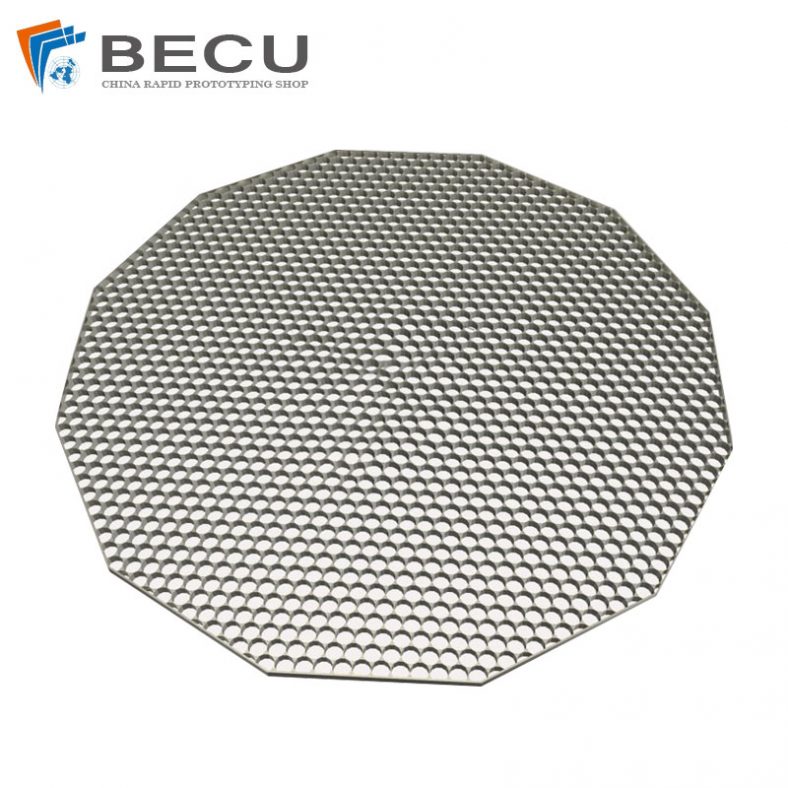

Precision Etched Titanium Alloy Odor Eliminator Perforated Plates

-

High-End Etched TC4 Titanium Alloy Filters

-

Aluminum Alloy 7075 Etched Microphone Grille

-

Molybdenum Screen and Spacecraft Electron Tube Grid Etching

-

Metal Etching Car Audio Modified Insulation Chips Shock Absorber Board Acoustic

-

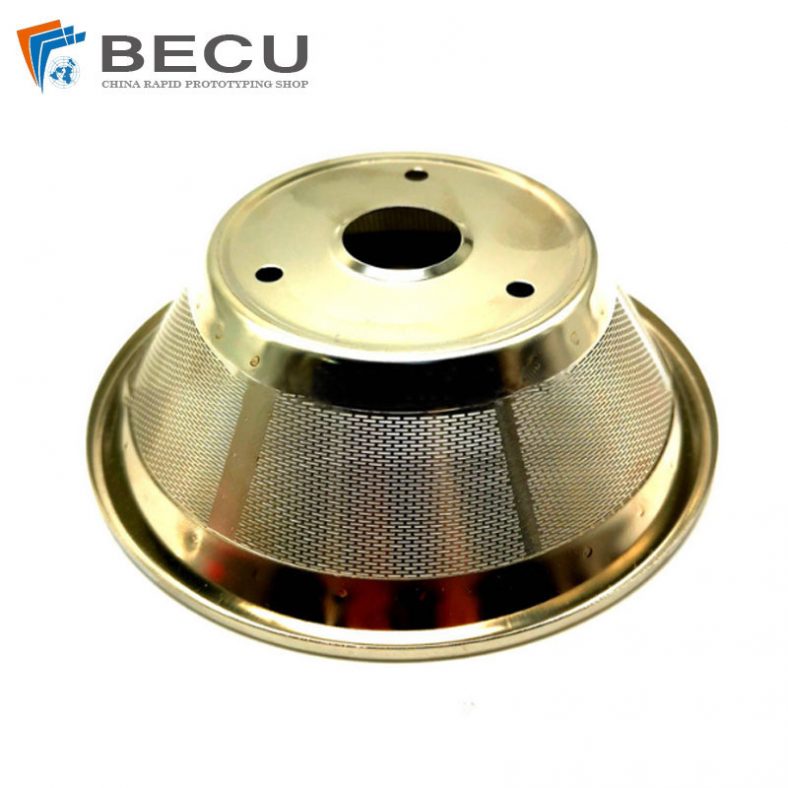

Etching 6.0 Inch Molybdenum Alloy Subwoofer Speaker Grill Guard Protector Cover for Home Audio

-

Precision Etching Titanium Alloy Hanging Fixture for Anodizing

-

Stainless Steel 316L Etching Tea Strainer

-

Zinc Alloy Nameplate Etching For Bags Logo/Signs

-

Russian Mythology Character Metal Nameplate Badge Etching

-

Aluminum Etching Car Audio Speaker Mesh

-

Precision Etching Stainless Steel Juicer Filter

-

Precision Etched Brass H62 Maple Leaf Bookmark

-

Three-Dimensional Etching Iron Candlestick

Metal Etching Certification,Equipment List and Quality

We are committed to enlisting the full support of all employees to continuously improve our processes and enhance quality, thereby fulfilling our customer's needs with defect free products and services, on time and every time

- ISO 9001:2015 certified

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process FMEA

- Fully compliant with the exacting requirements of our customers

- ITAR registered

- NIST cybersecurity standard compliant

- Proprietary Patented quality systems

- Skilled in KanBan and other customer driven quality and inventory management systems

Metal Etching Material

BE-CU is experienced in precision etching various metals, allowing customers the freedom to specify components in hundreds of different materials.

The Surface Treatment Of Metal Etching Parts

Do you want your etching parts to be more corrosion-resistant or get a specific look? Metal finishing service is a essential choice to achieve your design perfectly. BE-CU – metal-etch.com is an accomplished finished parts manufacturer, our workers and craftsman are capable to provide precision metal etching services and a wide range of finishing services including aluminum anodizing, painting, passivation, electroplating, powder coating, polishing, black oxide, conversion coating, abrasive blasting, etc. We offers several common surface finishes to help improve functionality and aesthetics.

- Anodizing (Anodized)

- Passivation

- Plating (Electroplating)

- Painting

- Black Oxide (Hot Blackening)

- Polishing

- Powder Coating

- Heat Treatment

- Satin Finish

- Abrasive blasting (Sandblasting)

- Conversion coating

- Tungsten carbide coating

After browsing a list of metal finishing services, select a process based on essential considerations, like production time, cost-effectiveness, part tolerance, durability and applications. High-tolerance metal etching parts are not recommended to apply secondary metal surface finish, because the treatment may change the sizes of the finished part through removing or adding a small amount of materials.

Other requirements or custom designs, welcome to contact us for a free quote fast!