Homepage » Metal Stamping » Progressive Stamping

Progressive Stamping

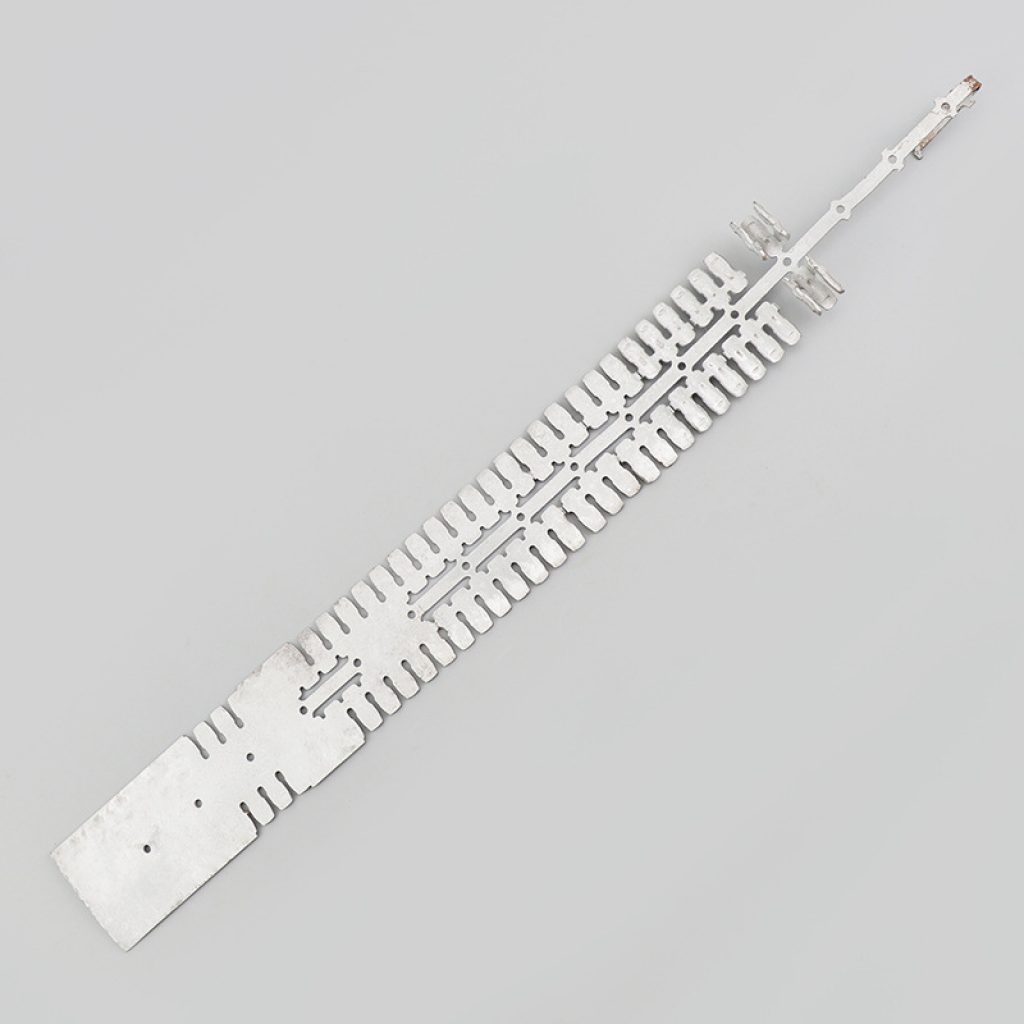

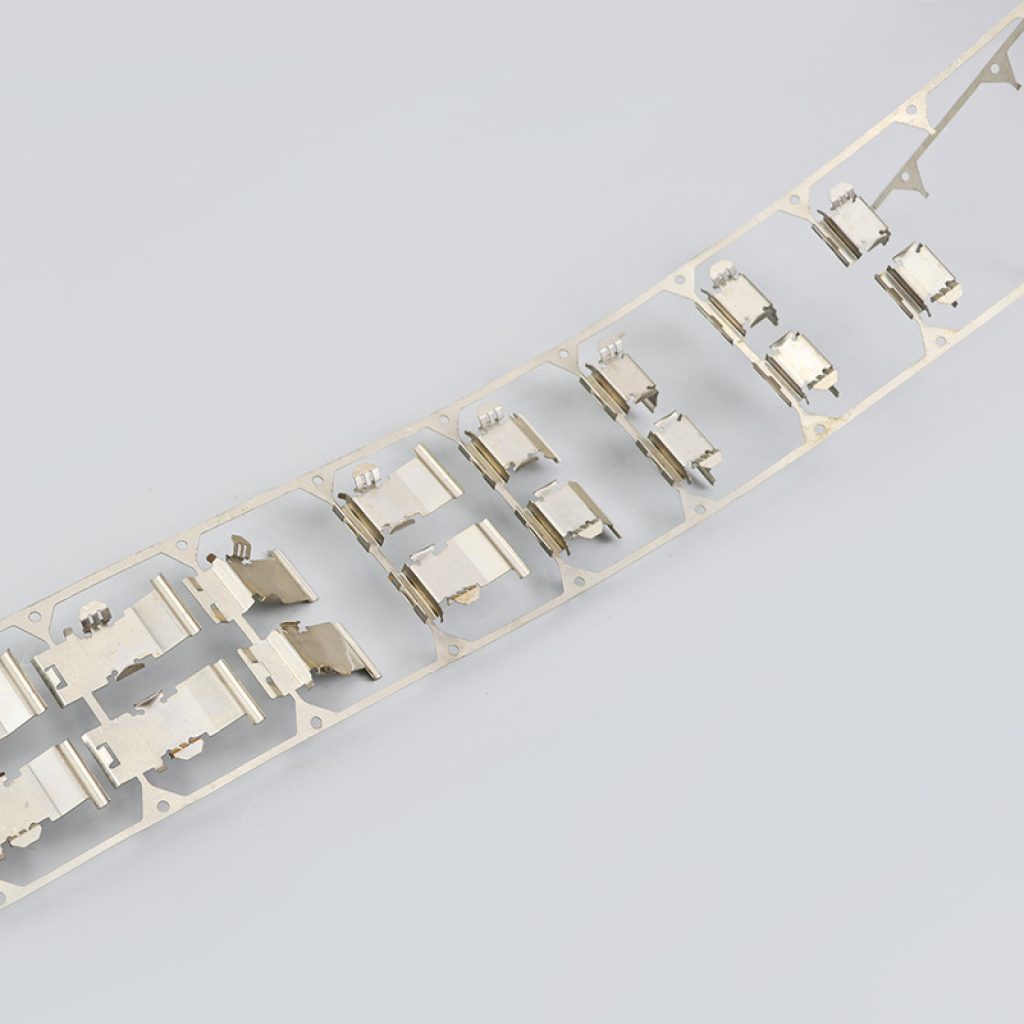

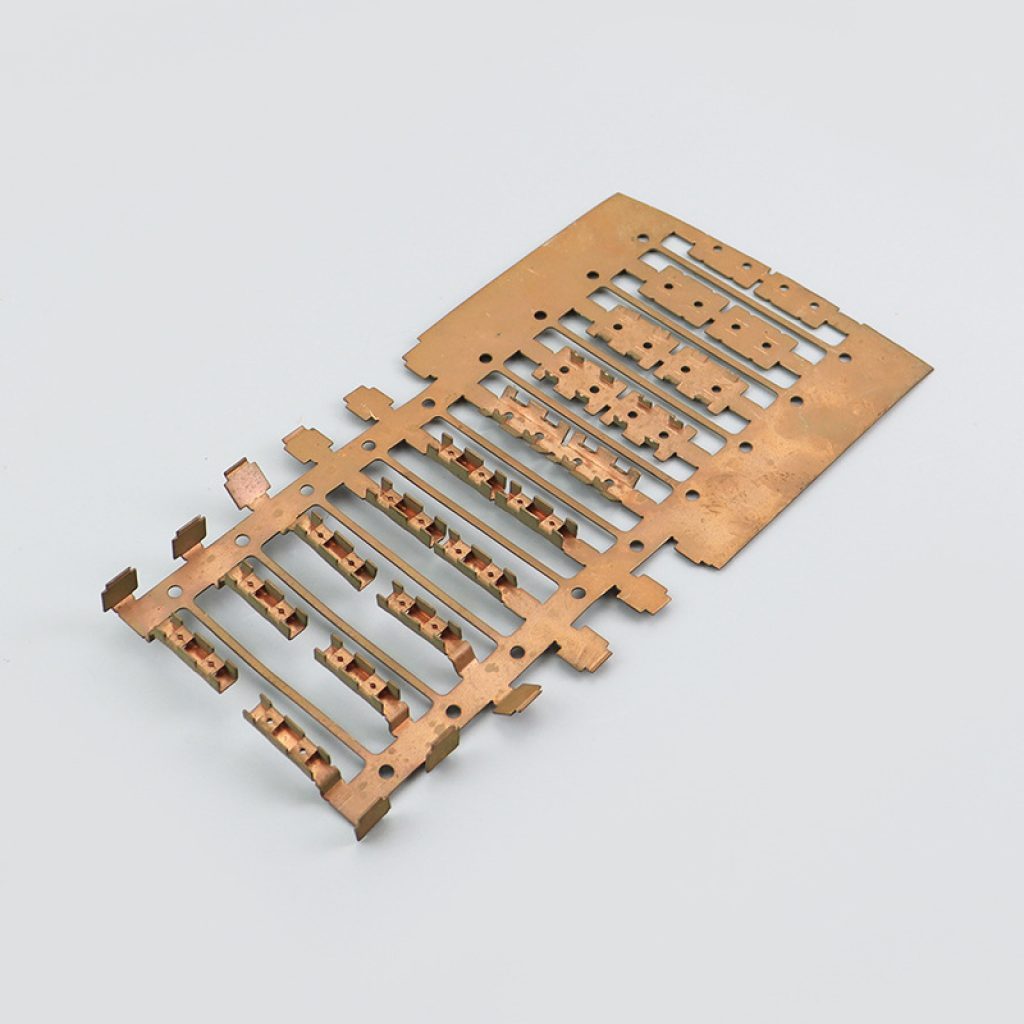

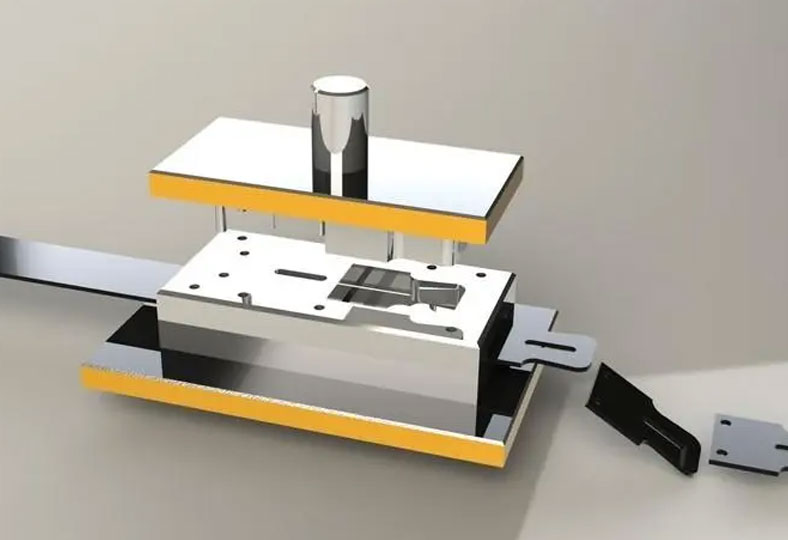

In this process, a metal strip is fed into a series of stations within a single die set. At each station, specific operations such as cutting, punching, bending, and forming are performed on the metal. As the strip passes through the die, a continuous series of operations takes place until the final component is formed.

Progressive die stamping is a metalworking process that efficiently produces large quantities of parts with consistent quality and precision.

The die set typically consists of multiple dies attached to a single tool assembly. These dies are arranged in a sequence that corresponds to the desired operation sequence needed to form the part. As the metal strip passes through the die set, each die performs a specific function, gradually shaping the part.

Progressive Die Stamping Company

Progressive die metal stamping helps save both time and costs. Progressive stamping and progressive die stamped parts are a specialty of Be-Cu Progressive Stamping. We promise to deliver high-quality, ultra-precision progressive stamping and small stamped parts. Our company is committed to maintaining fully predictable parts supply at any production volume or precision level.

Our commitment to timely delivery, consistent quality, and minimal cost is supported by a wide range of progressive stamping equipment listed in BE-CU’s stamping machinery portfolio.

Progressive Die Stamping Services

If your project requires thousands to millions of 3D metal parts, progressive tooling stamping is the ideal solution. Progressive die stamping is the most cost-effective custom metal stamping process.

Progressive die stamping can produce both simple and complex parts. Since we design and manufacture all progressive tools in-house, we can produce anything from seismic/earthquake shut-off valve components to locks and related hardware. Please send your project requirements to [email protected] now.

Advantages of Progressive Stamping

Progressive die stamping offers several advantages over other manufacturing methods, including fast production speeds, minimal material waste, and consistent part quality. It is commonly used in industries such as automotive, electronics, home appliances, and aerospace for manufacturing various components, such as brackets, clips, connectors, and stamped metal parts.Overall, progressive die stamping is a cost-effective and efficient manufacturing process for mass-producing metal parts with complex shapes and tight tolerances.

Materials Used in Progressive Die Stamping

Progressive die stamping can be applied to a wide range of materials depending on the specific requirements of the parts being manufactured. Common materials used in progressive die stamping include:

Steel Progressive Stamping

Aluminium Progressive Stamping

Copper Progressive Stamping

Brass Progressive Stamping

Bronze Progressive Stamping

Special Alloys Progressive Stamping

The type of progressive die stamping process varies depending on the materials used, the complexity of the parts, and the desired manufacturing results. However, the basic principle of progressive die stamping remains consistent across different materials: performing multiple steps at high speeds in a single die set to manufacture large volumes of parts with accuracy and efficiency.

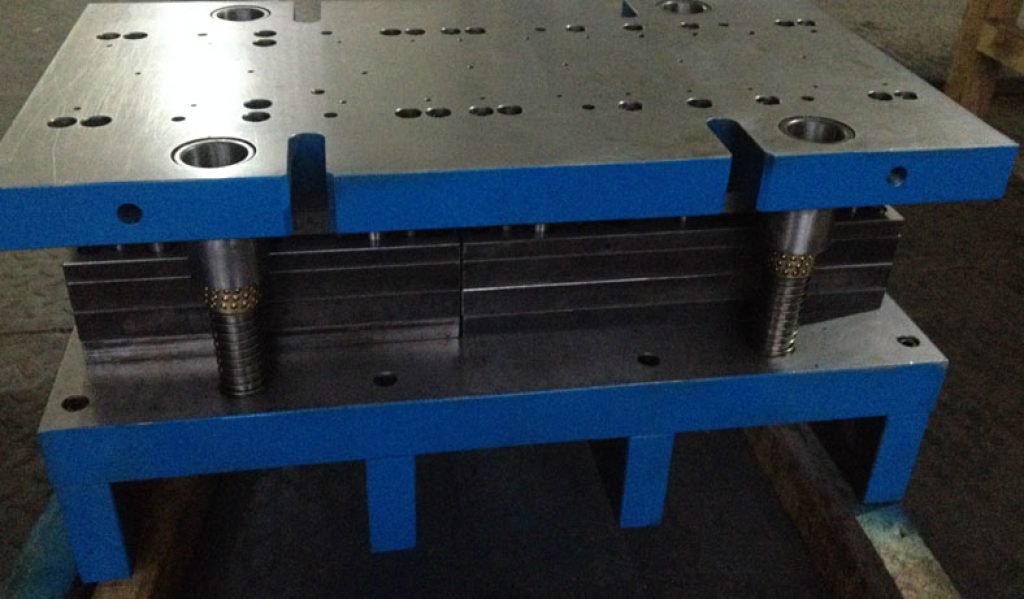

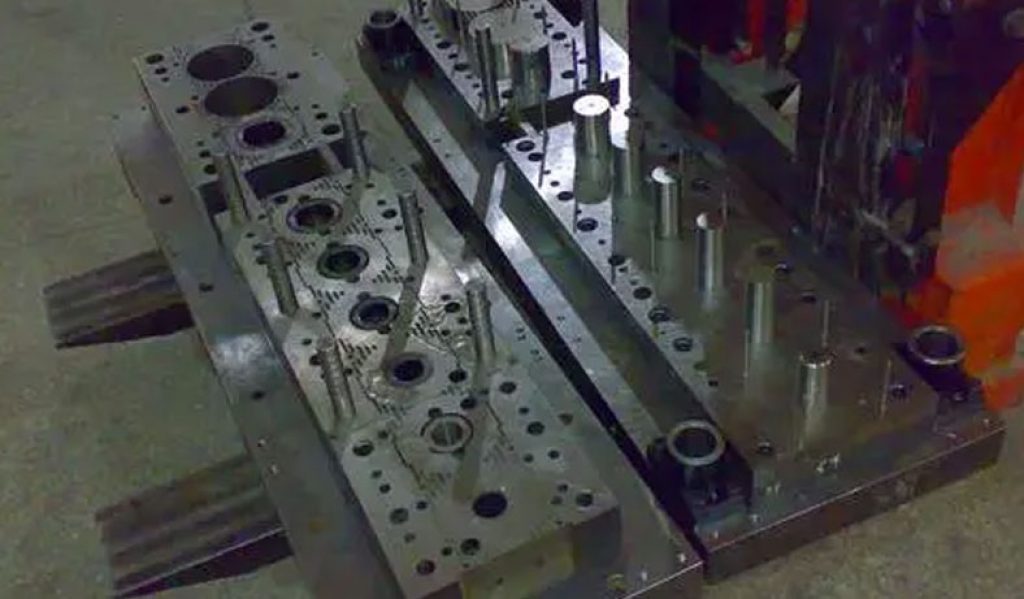

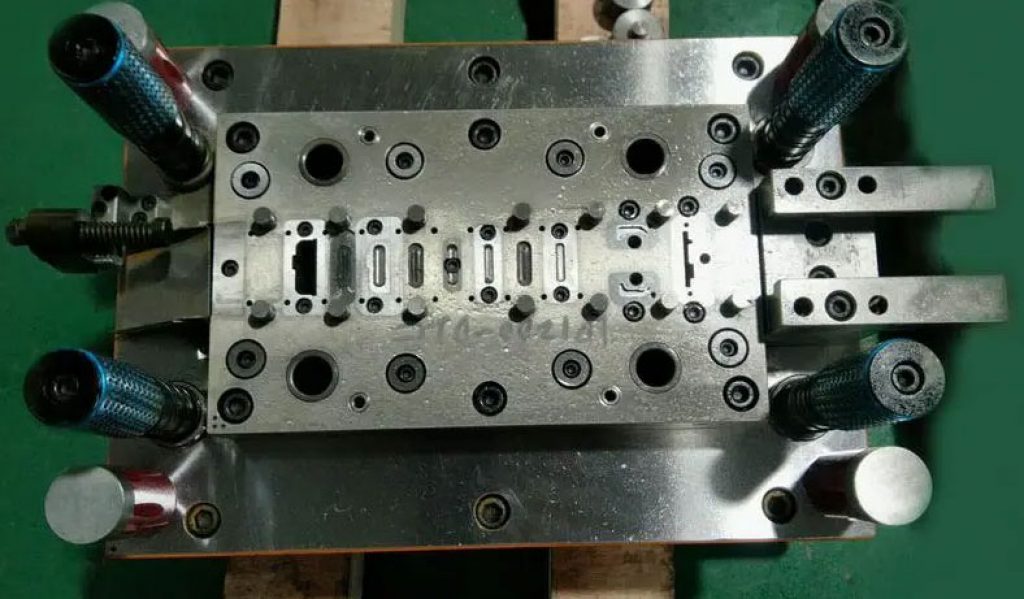

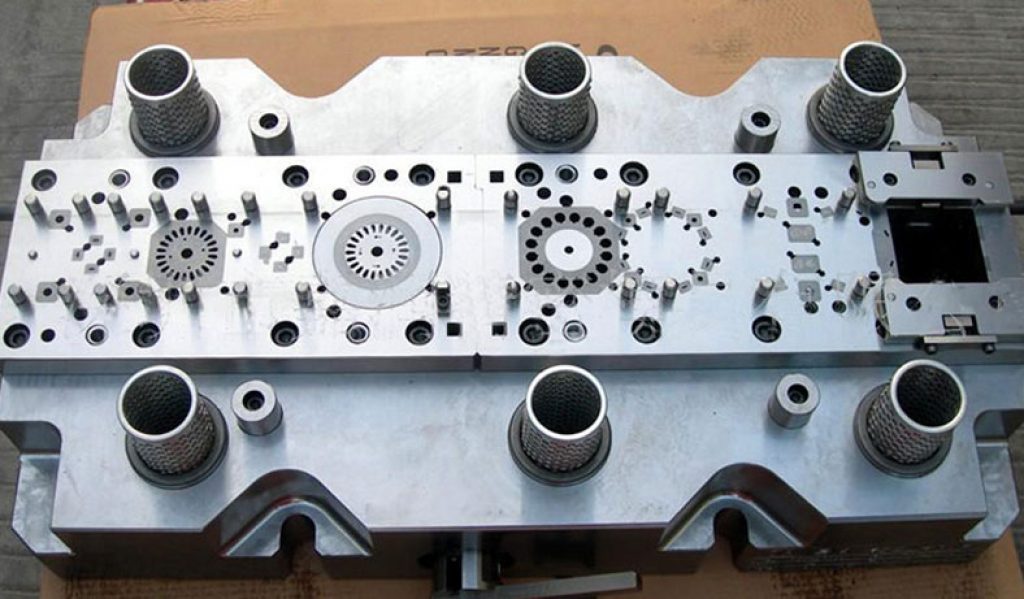

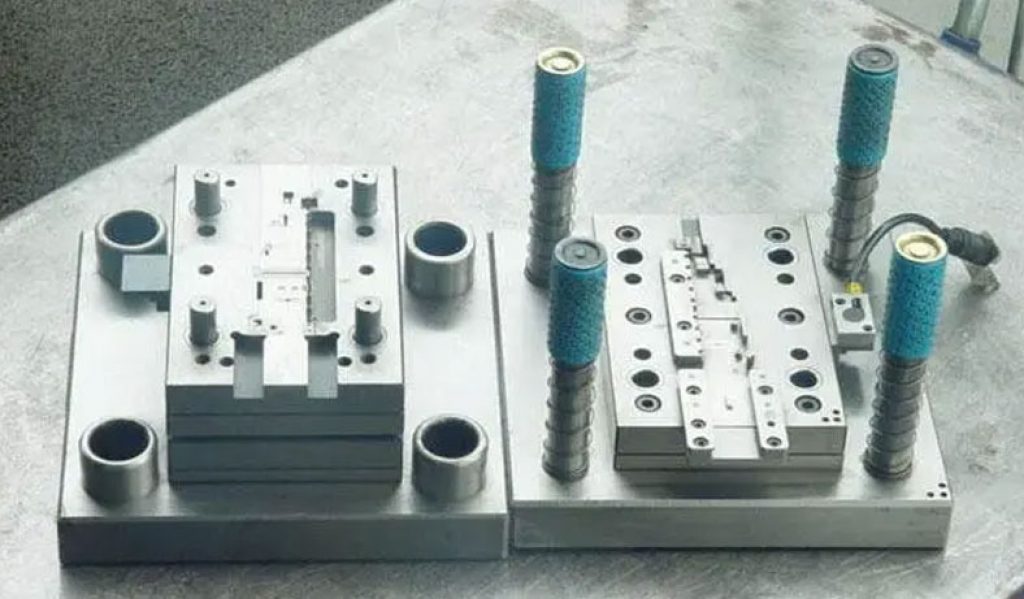

Progressive Stamping Dies and Tools for Mass Production

In progressive die stamping, tools called progressive dies are used. These tools contain multiple stamping stations that perform operations simultaneously on a metal strip. By combining all the necessary tools in a single die set, progressive die stamping becomes the optimal solution for mass production. Industries benefiting from progressive metal stamping include electronics, food and beverage, medical, home appliances, military, and automotive. Below are some examples of the dies we manufacture for our clients.

Automotive stainless steel continuous mold

Compressor motor progressive mold

Evaporator parallel flow plug progressive die

Motor core stamping die

Motor punching progressive die

Support plate progressive die

BE-CU Progressive Stamping Parts,Components and More

If you have a complex component design, BE-CU is here to help bring it to life. With the right equipment, strong technical expertise, and an unwavering commitment to quality, BE-CU Stamping Company ensures that every project is completed to the highest standards—from tool design through to finishing and shipment. We guarantee that all orders are delivered on time, every time.