Homepage » Metal Etching »

Precision Etching Steel Alloy – Steel Etching

Steel etching is a process used to create intricate designs or text on the surface of steel. This method, which has been employed for centuries, involves using chemical, mechanical, or electrical means to remove layers of steel in a controlled manner, thereby revealing the desired pattern or image. Steel etching has applications in various industries, including art, manufacturing, and security.

The origins of steel etching can be traced back to ancient times. Early artisans and craftsmen used basic etching techniques to decorate weapons, armor, and tools. The process evolved significantly during the Renaissance period when artists like Albrecht Dürer began using etching for creating detailed prints and illustrations.In its early stages, steel etching was performed manually. Craftsmen would use pointed tools to carve designs into the steel surface. This labor-intensive process required significant skill and precision. The introduction of acids, such as nitric acid, in the etching process marked a significant advancement. By applying acid to the steel surface, artisans could achieve more intricate and detailed designs with greater ease.

The Industrial Revolution brought about significant changes in the field of steel etching. Advances in technology and materials made the process more efficient and accessible. The development of electrochemical etching techniques, for example, allowed for greater precision and consistency in industrial applications. This period also saw the rise of photo-etching, a technique that uses photographic processes to transfer designs onto steel surfaces.

Our Steel Etching Service

With over 30 years of experience manufacturing steel parts, BE-CU ETCH Company offers a truly unparalleled level of expertise in custom steel etching. We work with both free machining and Naval steel and offer numerous plating options, including electroless nickel plating, which adds a less porous, all-enveloping barrier to etching steel parts for superior corrosion resistance. All of our precision etching operations adhere to strict quality standards, and our company is ISO 9001:2015-certified.

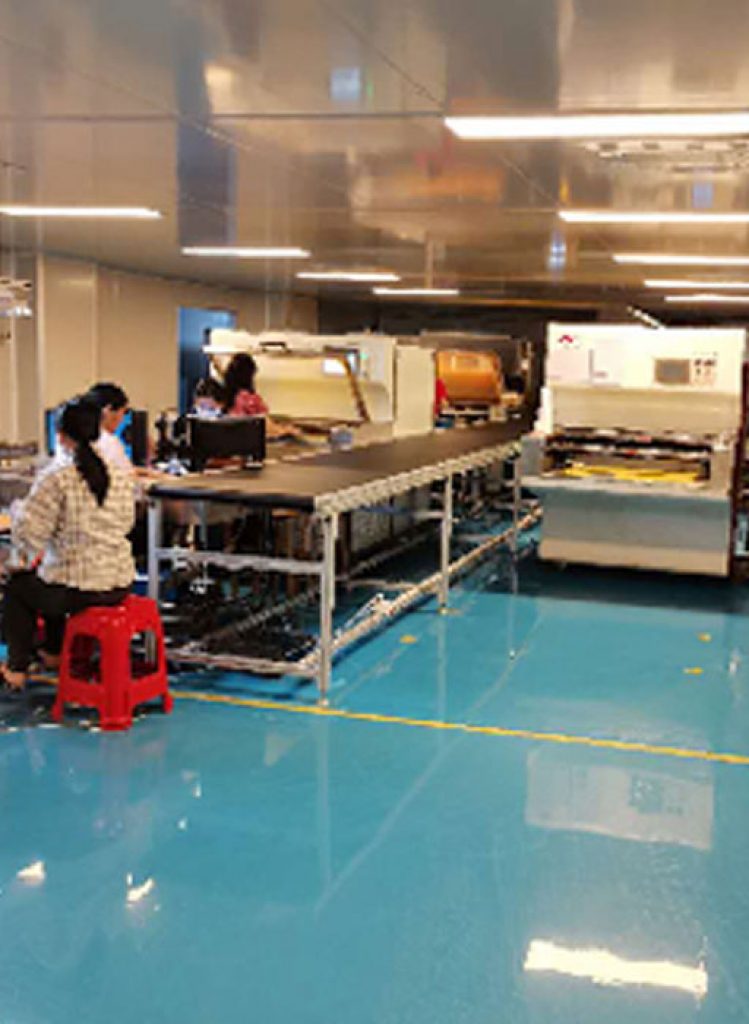

At BE-CU ETCH, we are proud to offer precision steel etching services for industries such as aerospace, medical, industrial, and defense. Our extensive knowledge and experience in etching steel parts allow us to deliver quality parts with tight tolerances. Our modern facility is equipped with a wide range of etching equipments to meet your unique requirements with precision and speed. To learn more about our steel etching services, contact us or request a quote today.

Etching Spring Steel

Spring steel is a group of medium to high-carbon steel alloys known for their high yield strength and ability to return to their original shape after deformation.

This property makes them ideal for producing springs, tools, and other high-stress components. Etching spring steel can be challenging due to its high hardness and strength, but with the right techniques and considerations, it can yield precise and detailed results.

Our Etching Capabilities

- Etching of many grades of steel alloys

- Combining Stamping, Laser Cutting,CNC machining and photochemical etching on sheets up to 2mm thick

- Etching of up to 0.025″ thick sheets as large as 22×12 inches

- Tolerances of ±.0005″ in many applications

How To Etch Steel

Automated-Coating

Automatic-Baking-Line

Automatic-Shearing

Coating-For-Etching-Parts

Deinking

Etching

Exposure

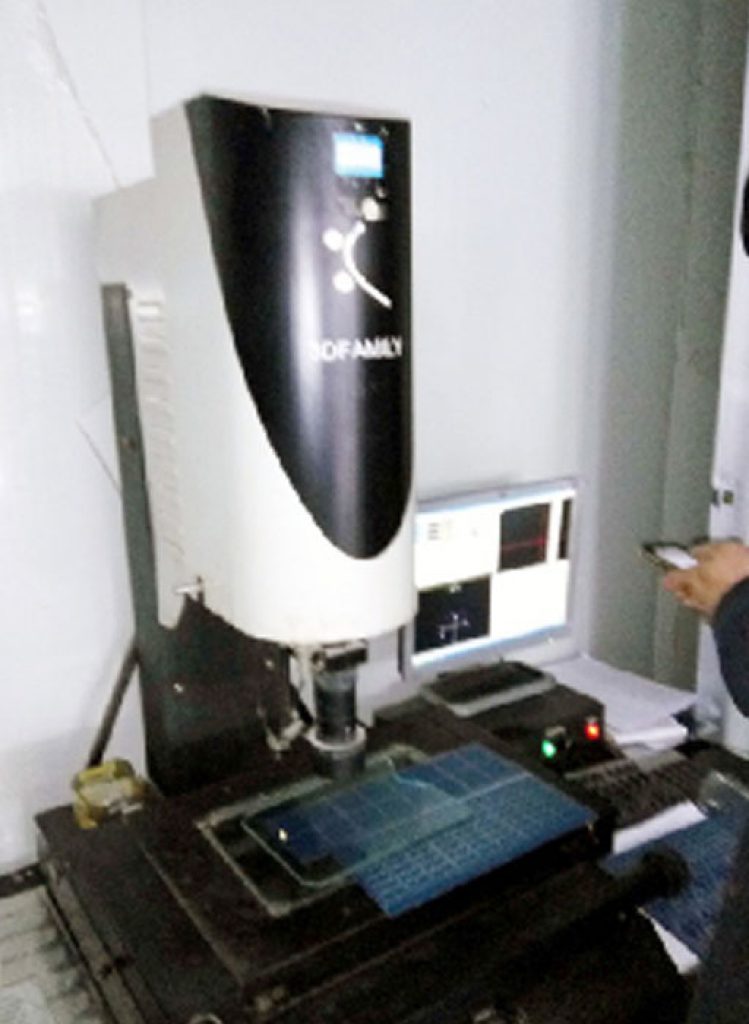

Inspection-For-Etching

Metal Grades For Steel Etching

The choice of steel grade is a crucial factor in the etching process, as different grades of steel have varying properties that can affect the quality and efficiency of the etching. Selecting the appropriate steel grade ensures that the etching process yields the desired results, whether for artistic, industrial, or functional purposes. The most common steel grades for etching are as follows:

AISI 1018

AISI 1045

AISI 1095

AISI 4130

AISI 4140

AISI O1

AISI D2

More Steel

By understanding the properties and applications of different steel grades, artisans and manufacturers can make informed decisions that enhance the quality and durability of their etched steel products.

Components That Are Produced By Etching Steel

The popularity of steel makes it a desirable metal for use in fabrication because it is easy to manufacture and has favorable properties for many industrial products.With the photo etching process, the metal is etched evenly without any structural deformations from the hard tooling used in stamping and punching.Since there isn’t a heat point of contact like laser cutting, the parts’ metal properties remain unchanged and free from thermal deformations.Get inspired by our custom etching part projects and contact us to Get Instant Quote for rapid prototype or steel etching parts start from 1pcs.

-

Stainless Steel 316L Etching Tea Strainer

-

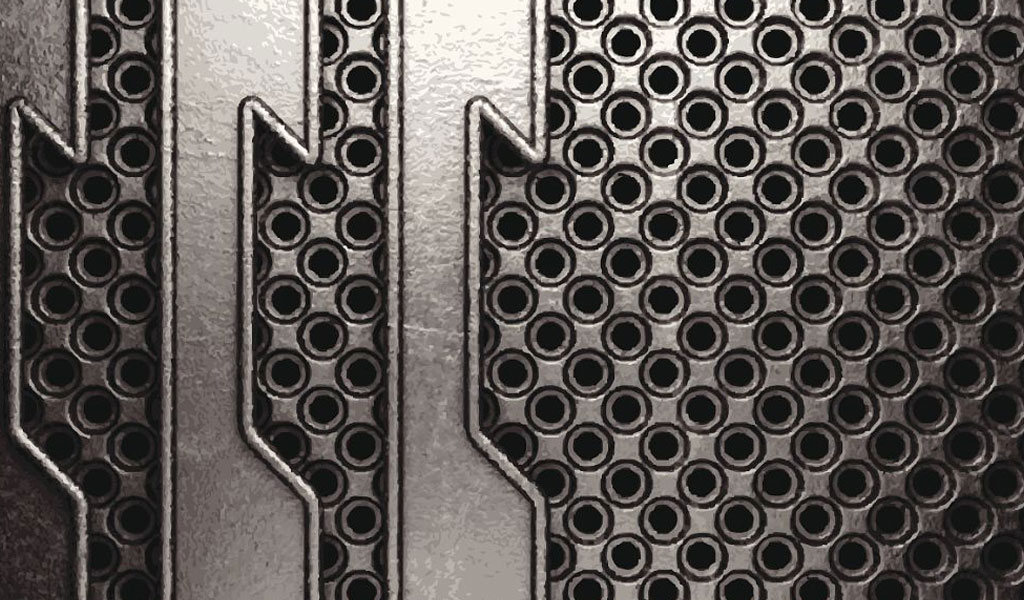

Russian Mythology Character Metal Nameplate Badge Etching

-

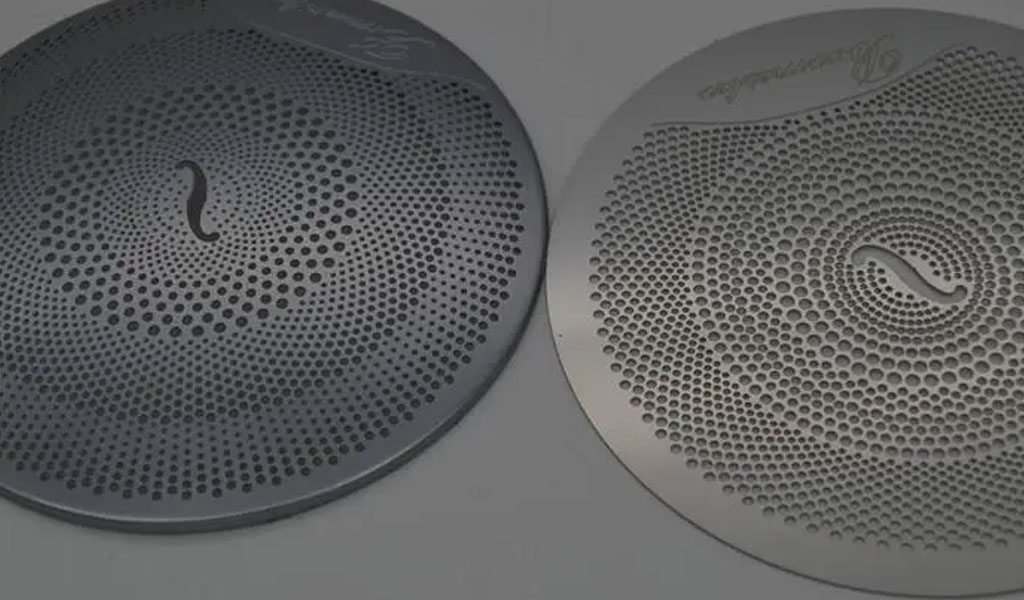

Precision Etching Stainless Steel Juicer Filter

-

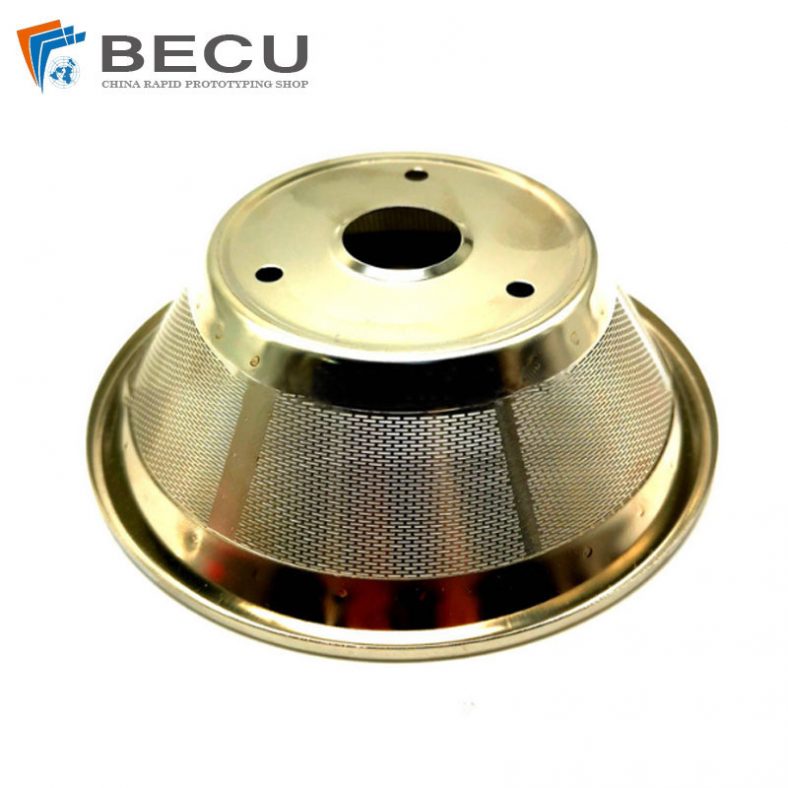

3D Etched Special-Shaped Stainless Steel 304 Spinning Lampshade

-

430 Stainless Steel Photoelectric Encoder Code Disc Etching

-

Stainless Steel 304 Wedge Filter Etching

-

High Speed 316L Hair Dryer Mesh Etching

-

Metal Etched Stainless Steel 304 Insect Screen

-

Chemical Etched Stainless Steel 304 Tea Screen Filter

-

Stainless Steel 316 Metal Etched Paring Planer

-

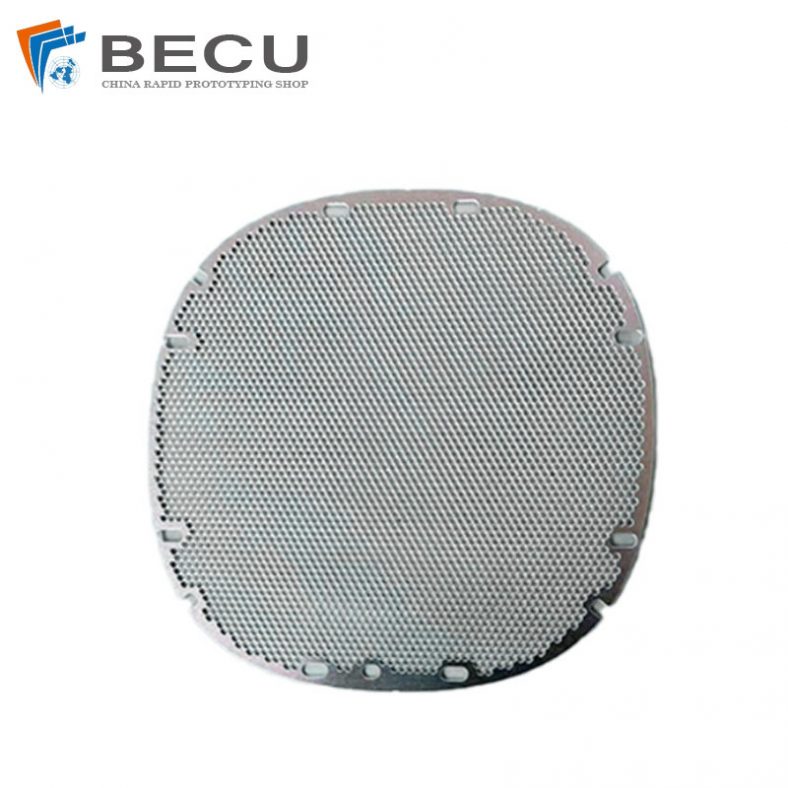

Microporous Etching Stainless Steel 17-4 ph Speaker Mesh

-

Metal Etching Stainless Steel 430 Hair Dryer Air Outlet Net

-

Electric KN95 Mask Breathing Valve Filter

-

Precision Etched Fuel Injector Nozzle Filter

-

Stainless Steel Etching Black Vacuum Blower Plate

-

0.2mm Etched High Speed Hair Dryer Mesh

Metal Etching Certification,Equipment List and Quality

We are committed to enlisting the full support of all employees to continuously improve our processes and enhance quality, thereby fulfilling our customer's needs with defect free products and services, on time and every time

- ISO 9001:2015 certified

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process FMEA

- Fully compliant with the exacting requirements of our customers

- ITAR registered

- NIST cybersecurity standard compliant

- Proprietary Patented quality systems

- Skilled in KanBan and other customer driven quality and inventory management systems

Metal Etching Material

BE-CU is experienced in precision etching various metals, allowing customers the freedom to specify components in hundreds of different materials.

The Surface Treatment Of Metal Etching Parts

Do you want your etching parts to be more corrosion-resistant or get a specific look? Metal finishing service is a essential choice to achieve your design perfectly. BE-CU – metal-etch.com is an accomplished finished parts manufacturer, our workers and craftsman are capable to provide precision metal etching services and a wide range of finishing services including aluminum anodizing, painting, passivation, electroplating, powder coating, polishing, black oxide, conversion coating, abrasive blasting, etc. We offers several common surface finishes to help improve functionality and aesthetics.

- Anodizing (Anodized)

- Passivation

- Plating (Electroplating)

- Painting

- Black Oxide (Hot Blackening)

- Polishing

- Powder Coating

- Heat Treatment

- Satin Finish

- Abrasive blasting (Sandblasting)

- Conversion coating

- Tungsten carbide coating

After browsing a list of metal finishing services, select a process based on essential considerations, like production time, cost-effectiveness, part tolerance, durability and applications. High-tolerance metal etching parts are not recommended to apply secondary metal surface finish, because the treatment may change the sizes of the finished part through removing or adding a small amount of materials.

Other requirements or custom designs, welcome to contact us for a free quote fast!