Homepage » Metal Etching »

Toy Etching – Metal Etching for Toy Industries

Toy etching is a specialized form of surface modification that involves the precise removal of material from the surface of a toy using various etching techniques. The primary purpose of toy etching is to enhance the appearance, functionality, and durability of toys, while also providing intricate designs and textures that can increase their appeal. The process can be applied to various types of materials, including plastic, metal, wood, and other substrates commonly used in toy manufacturing.

The use of etching as a decorative technique dates back to ancient civilizations, where it was employed to create detailed designs on metals and ceramics. However, the application of etching to toys is a relatively modern development, emerging alongside the industrialization of toy production in the late 19th and early 20th centuries.

The growing demand for mass-produced toys with intricate details led to the adoption of new technologies, including etching, to create designs that were both aesthetically appealing and cost-effective.

Toy etching gained significant prominence in the mid-20th century with the rise of plastic toys, which provided manufacturers with a versatile and affordable medium for intricate designs. The ability to etch fine patterns into plastic surfaces allowed manufacturers to create toys with more intricate and personalized details, from character likenesses to logos and brand marks. Over time, toy etching evolved to include not just decoration but also functional features such as textured grips, patterns for educational purposes, and even specialized marking for safety and compliance.

Our Toy Etching Service

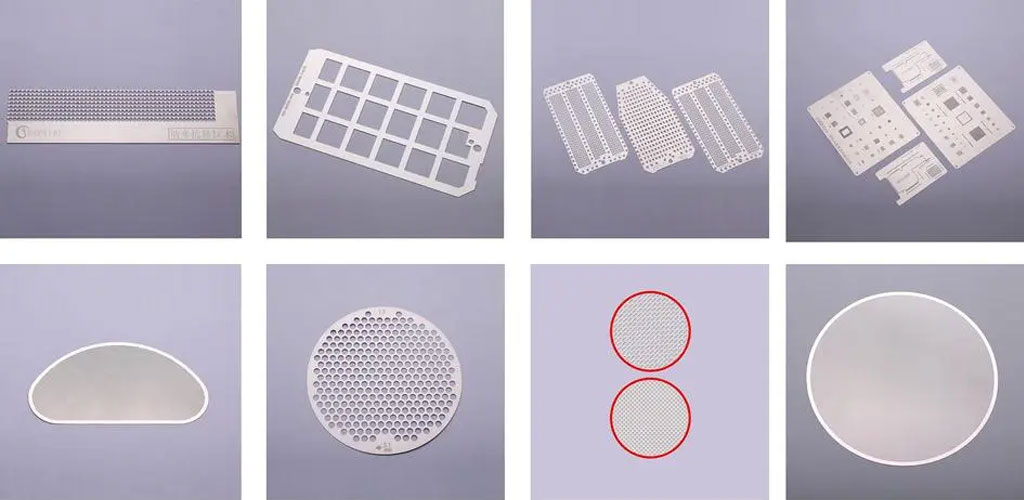

If you need Toy etched we are one of the most capable and affordable sources specializing in manufacturing custom etched parts on advanced photo etching machines with cnc precision. Through our Photo Chemical Etching process, the smallest and most complex designs are made possible such as electrical spring contacts, contact membranes, busbars, antennae and micro antennae, spring fingered contacts, heating elements and battery terminal as well as many other bespoke components to your own designs.

We can machine to print and accept the most common file formats including: .dwg .dxf .iges .step .sat as well as .pdf files. If you don’t see your file format here let us know. Please send us files to: [email protected] We can accept both small and large run jobs of custom toy.

Our Etching Capabilities

- Etching of many grades of metal and more

- Combining Stamping, Laser Cutting,CNC machining and photochemical etching on sheets up to 2mm thick

- Etching of up to 0.025″ thick sheets as large as 22×12 inches

- Tolerances of ±.0005″ in many applications

How To Etch Toy Parts

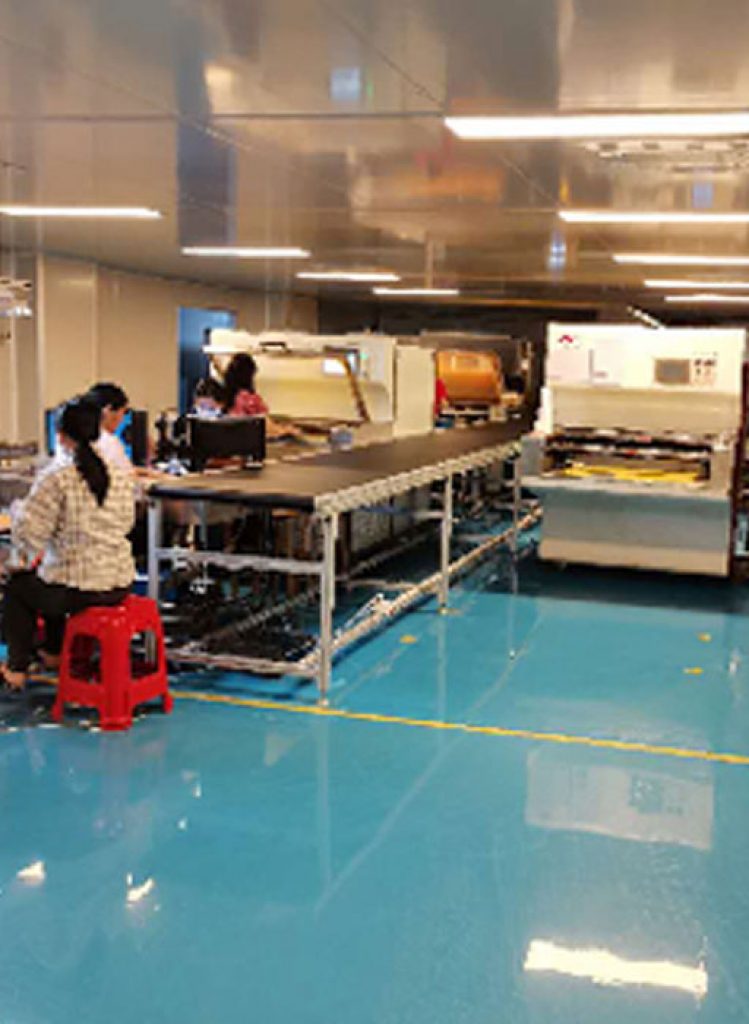

Automated-Coating

Automatic-Baking-Line

Automatic-Shearing

Coating-For-Etching-Parts

Deinking

Etching

Exposure

Inspection-For-Etching

Materials Used in Toy Etching

The materials used for toy etching are diverse, reflecting the broad range of toy types and materials available in the market. Some of the most common materials used in toy etching include:

Plastic

Plastics, such as polyethylene (PE), polyvinyl chloride (PVC), polystyrene (PS), and ABS (acrylonitrile butadiene styrene), are some of the most widely used materials in the toy industry. These materials can be etched using a variety of techniques, including laser etching and chemical etching. Plastics are chosen for their versatility, ease of molding, and relatively low cost. Etching plastic toys allows manufacturers to add intricate designs and branding logos that are often a key part of a toy’s appeal.

Metal

Metal toys, such as those made from die-cast aluminum, brass, or stainless steel, are also popular candidates for etching. Metal etching can be done using chemical etching, laser etching, or mechanical etching, and it allows for the creation of highly detailed and durable designs. Metal-etched toys often have a more sophisticated appearance and can carry more intricate, precise patterns than plastic toys.

Wood

Wood is another material that can be etched, often using laser etching or mechanical methods. Wood-etched toys can feature detailed illustrations, branding, and textural designs that appeal to consumers looking for eco-friendly and natural toys. Wood etching is also widely used for toys that require personalization, such as wooden puzzles, dolls, and figurines。

Glass

Although less common than plastic and metal, glass is sometimes used in toy production, particularly for decorative items, collectibles, or educational toys. Glass etching involves the use of abrasive techniques or acid to create frosted designs on the surface of the material. Etched glass toys can be highly decorative and often serve as unique collector’s items。

Applications of Toy Etching

Toy etching is used in a variety of applications, each serving different functions within the toy manufacturing industry. Some of the most notable applications of toy etching include:

- Branding and Logos : One of the primary uses of etching in toy manufacturing is to add logos, brand marks, and trademark designs to toys. Etched logos help establish brand identity and ensure that consumers can easily identify genuine products from a specific manufacturer. This is especially important in the competitive toy industry, where brand recognition can significantly influence consumer purchasing decisions.

- Text and Labels : Etching is also used to add text to toys, such as product names, instructions, warnings, or safety information. These labels are crucial for ensuring compliance with regulatory standards and providing consumers with the necessary information about the toy’s use. Etching text into toys offers a durable, permanent solution to labeling, particularly for toys that undergo frequent handling or washing.

- Decorative Designs : Etching provides a versatile way to add decorative designs to toys. Whether it is intricate patterns on toy figurines, texture details on doll accessories, or artistic elements on toy packaging, etching can be used to create visually appealing and detailed designs. The ability to add fine details without the need for additional materials makes etching an attractive option for toy manufacturers looking to differentiate their products.

- Educational Features : In some cases, toy etching is used to create educational designs that promote learning. For example, etching numbers, letters, or shapes onto toys helps children learn to recognize and identify key concepts. Etched toys, such as puzzles or games, can also include textures or patterns that stimulate a child’s sense of touch, aiding in the development of motor skills and sensory perception.

- Functional Features : Etching is not always purely decorative; it can also serve functional purposes. For example, etching grip patterns into toy tools or playsets ensures that they are easy to handle, improving their usability. Similarly, etching surfaces to create texture on toys like building blocks can help with their tactile appeal and make them easier for children to manipulate.

- Personalization : Personalized etching is becoming increasingly popular in the toy industry. Whether it’s custom names, birthdates, or messages, personalized toys have become a trend among gift-giving and memorabilia. Etching allows manufacturers to offer a high level of customization, making toys more unique and meaningful for consumers.

Components That Are Produced By Etching Toy

The popularity of Toy makes it a desirable metal for use in fabrication because it is easy to manufacture and has favorable properties for many industrial products.With the photo etching process, the metal is etched evenly without any structural deformations from the hard tooling used in stamping and punching.Since there isn’t a heat point of contact like laser cutting, the parts’ metal properties remain unchanged and free from thermal deformations.Get inspired by our custom etching part projects and contact us to Get Instant Quote for rapid prototype or Toy etching start from 1pcs.

-

Copperplate Engravings Of World Famous Works

-

Artistic Etched Copper Shielding Electronics Playing Cards with Patterns

-

Zinc Alloy Nameplate Etching For Bags Logo/Signs

-

3D Etching Brass H62 Incense Burner

-

Brass 360 Hollow Etched Hangtag

-

Precision Etching H59 Butterfly Pendant Jewelry

-

Laser Etching H62 Brass Pendant Jewelry

-

Aluminum Alloy 6061 Etched Bookmark

Metal Etching Certification,Equipment List and Quality

We are committed to enlisting the full support of all employees to continuously improve our processes and enhance quality, thereby fulfilling our customer's needs with defect free products and services, on time and every time

- ISO 9001:2015 certified

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process FMEA

- Fully compliant with the exacting requirements of our customers

- ITAR registered

- NIST cybersecurity standard compliant

- Proprietary Patented quality systems

- Skilled in KanBan and other customer driven quality and inventory management systems

Metal Etching Material

BE-CU is experienced in precision etching various metals, allowing customers the freedom to specify components in hundreds of different materials.

The Surface Treatment Of Metal Etching Parts

Do you want your etching parts to be more corrosion-resistant or get a specific look? Metal finishing service is a essential choice to achieve your design perfectly. BE-CU – metal-etch.com is an accomplished finished parts manufacturer, our workers and craftsman are capable to provide precision metal etching services and a wide range of finishing services including aluminum anodizing, painting, passivation, electroplating, powder coating, polishing, black oxide, conversion coating, abrasive blasting, etc. We offers several common surface finishes to help improve functionality and aesthetics.

- Anodizing (Anodized)

- Passivation

- Plating (Electroplating)

- Painting

- Black Oxide (Hot Blackening)

- Polishing

- Powder Coating

- Heat Treatment

- Satin Finish

- Abrasive blasting (Sandblasting)

- Conversion coating

- Tungsten carbide coating

After browsing a list of metal finishing services, select a process based on essential considerations, like production time, cost-effectiveness, part tolerance, durability and applications. High-tolerance metal etching parts are not recommended to apply secondary metal surface finish, because the treatment may change the sizes of the finished part through removing or adding a small amount of materials.

Other requirements or custom designs, welcome to contact us for a free quote fast!