Homepage » Metal Etching »

Military Etching – Metal Etching for Military Industries

Military etching refers to the process of creating intricate and precise designs or markings on materials, such as metals, that are used in military applications. This process is essential for the production of a wide variety of military components and accessories, including identification tags, badges, parts for aircraft and vehicles, and even weapons systems.

Military etching serves not only a functional role in identifying and categorizing equipment but also contributes to the aesthetic appeal and symbolism that are often integral to military traditions and culture.

In the early days, military etching was primarily used for creating unique markings on firearms, ammunition, and equipment, as well as for crafting badges and insignia. As military technologies advanced, so too did the need for more specialized and durable methods of etching. The development of chemical etching techniques, as well as the introduction of automated machinery, significantly increased the precision and efficiency of the etching process.

Our Military Etching Service

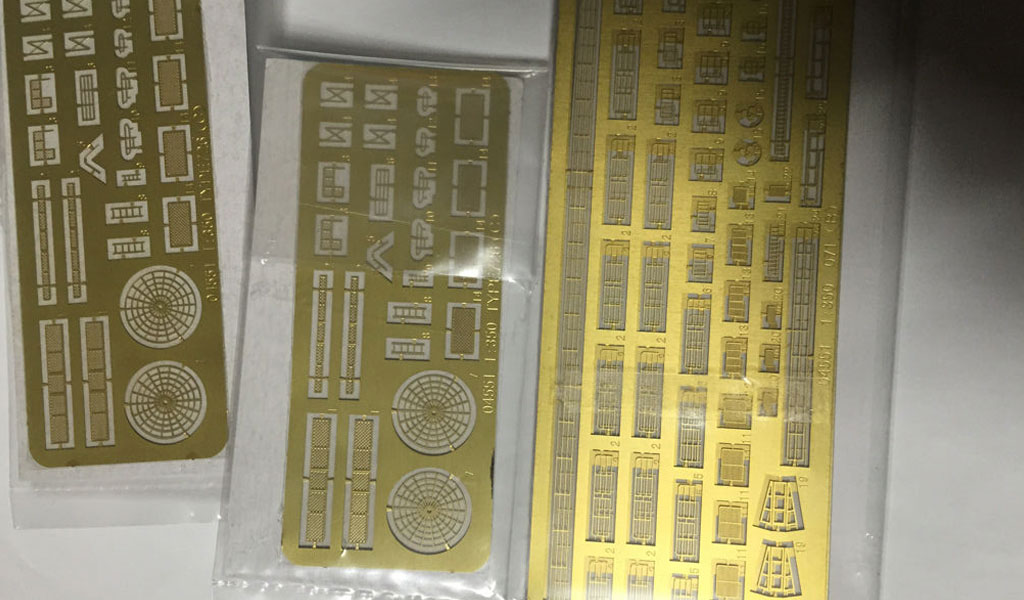

If you need Military parts etched we are one of the most capable and affordable sources specializing in manufacturing custom etched parts on advanced photo etching machines with cnc precision. Through our Photo Chemical Etching process, the smallest and most complex designs are made possible such as electrical spring contacts, contact membranes, busbars, antennae and micro antennae, spring fingered contacts, heating elements and battery terminal as well as many other bespoke components to your own designs.

We can machine to print and accept the most common file formats including: .dwg .dxf .iges .step .sat as well as .pdf files. If you don’t see your file format here let us know. Please send us files to: [email protected] We can accept both small and large run jobs of custom Military etching parts.

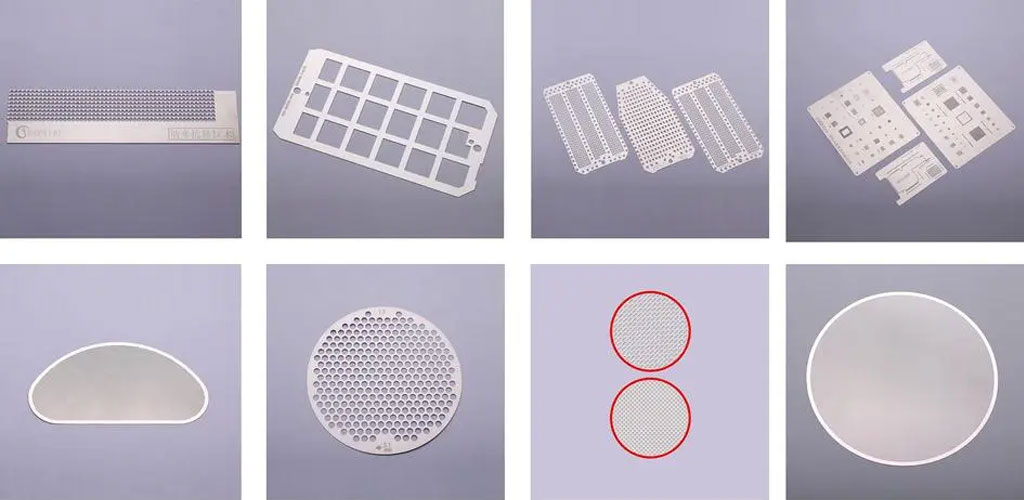

Our Etching Capabilities

- Etching of many grades of metal and more

- Combining Stamping, Laser Cutting,CNC machining and photochemical etching on sheets up to 2mm thick

- Etching of up to 0.025″ thick sheets as large as 22×12 inches

- Tolerances of ±.0005″ in many applications

How To Etch Military Parts

Automated-Coating

Automatic-Baking-Line

Automatic-Shearing

Coating-For-Etching-Parts

Deinking

Etching

Exposure

Inspection-For-Etching

Materials Used in Military Etching

Military etching involves the use of various materials, primarily metals and alloys, that are commonly found in military-grade equipment. The selection of materials is crucial, as it ensures the durability, strength, and corrosion resistance required for use in harsh environments.

Stainless Steel

Stainless steel is one of the most commonly used materials in military etching. It is highly resistant to corrosion, which is essential for components exposed to extreme weather conditions or harsh chemicals. Stainless steel is used for etching identification tags, serial numbers, and other components that require durability and resistance to wear.

Titanium

Titanium is another widely used material in military etching, particularly in aerospace applications. Known for its excellent strength-to-weight ratio and resistance to high temperatures, titanium is used in components like aircraft parts, missiles, and other military hardware. Titanium etching provides high levels of precision and clarity, making it ideal for marking intricate designs.

Aluminum

Aluminum is commonly used in military etching, especially for lightweight components such as aircraft parts, military vehicles, and structural elements. Aluminum alloys are prized for their strength, lightness, and resistance to corrosion, making them suitable for military equipment that needs to perform in demanding environments

Copper and Brass

Copper and brass are often used in the etching of decorative elements, such as military medals, badges, and insignia. These materials are softer than steel or titanium but are still durable and provide an excellent surface for intricate designs. Copper and brass also have good resistance to corrosion, although they are more commonly used in items that are less exposed to extreme conditions.

Nickel Alloys

Nickel alloys, such as Inconel, are highly resistant to heat and corrosion and are often used in military applications where components are exposed to extreme temperatures, such as jet engines, turbine blades, and other high-performance parts. The etching of these materials requires precision and expertise, as the alloys can be difficult to work with using traditional methods.

Plastics and Polymers

While metals dominate military etching, plastics and polymers are sometimes used, especially for non-structural components or electronic enclosures. These materials are etched using laser technology and are often used for creating labels, identification numbers, and safety warnings on military equipment.

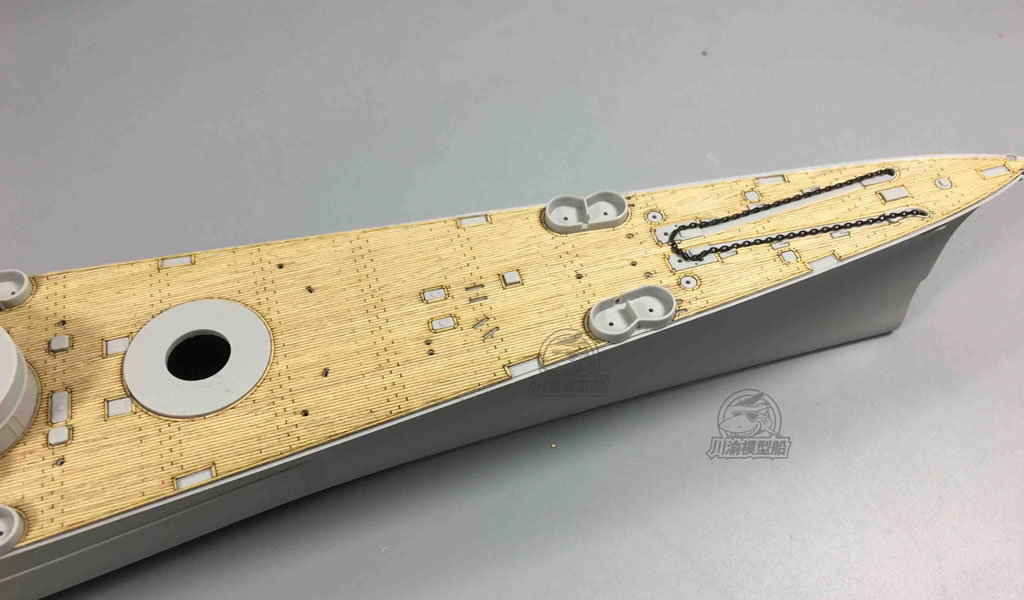

Applications of Military Etching

Military etching is used in a wide range of applications, all of which are essential to ensuring the proper functioning, identification, and longevity of military equipment. Some of the most prominent uses of etching in the military include:

- Identification Tags and Markings:Military identification tags, or dog tags, are perhaps the most well-known examples of military etching. These tags are etched with personal information, such as a soldier’s name, rank, and serial number. Etching is also used to mark various military items with serial numbers, batch numbers, or other identifiers, ensuring that equipment can be tracked and maintained over time.

- Badges and Insignia:Military personnel often wear badges and insignia that indicate rank, unit affiliation, and awards. These markings are typically etched into metal or other durable materials, creating symbols and emblems that carry significant meaning within the military context. Etching provides a level of precision that allows for intricate designs to be faithfully reproduced on small, detailed surfaces.

- Aircraft and Aerospace Components:In the aerospace and aviation sectors, military etching is used to mark components such as turbine blades, engine parts, and avionics. These markings are critical for tracking the maintenance and service history of components, ensuring safety and compliance with military standards. Etching also plays a role in the aesthetic design of military aircraft, where insignia, aircraft numbers, and mission markings are added to the surface of the planes.

- Weaponry:Firearms, ammunition, and other weaponry are often etched with serial numbers, logos, and safety markings. Etching is used to provide clear identification and to prevent counterfeit products from entering the market. For example, military rifles and handguns may be etched with the manufacturer’s logo, serial number, and government stamps to confirm their authenticity.

- Tactical Equipment:Military etching is also employed in the marking of tactical equipment such as helmets, body armor, night vision goggles, and communication devices. Etching ensures that these items are traceable and identifiable, reducing the risk of loss or misplacement.

- Commemorative and Symbolic Items:Military units often use etching to commemorate special events, missions, or individuals. Items such as plaques, medals, and ceremonial swords can be etched with special symbols or inscriptions to recognize accomplishments and milestones. These items are often prized by military personnel and serve as symbols of honor and achievement.

- Military Vehicle Components:Military vehicles, such as tanks, trucks, and armored personnel carriers, often feature etched markings that indicate the vehicle’s unit, model, and maintenance history. Etching ensures that each component of the vehicle is identifiable and can be tracked throughout its service life.

Components That Are Produced By Etching Military Parts

The popularity of Military makes it a desirable metal for use in fabrication because it is easy to manufacture and has favorable properties for many industrial products.With the photo etching process, the metal is etched evenly without any structural deformations from the hard tooling used in stamping and punching.Since there isn’t a heat point of contact like laser cutting, the parts’ metal properties remain unchanged and free from thermal deformations.Get inspired by our custom etching part projects and contact us to Get Instant Quote for rapid prototype or Military etching parts start from 1pcs.

Metal Etching Certification,Equipment List and Quality

We are committed to enlisting the full support of all employees to continuously improve our processes and enhance quality, thereby fulfilling our customer's needs with defect free products and services, on time and every time

- ISO 9001:2015 certified

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process FMEA

- Fully compliant with the exacting requirements of our customers

- ITAR registered

- NIST cybersecurity standard compliant

- Proprietary Patented quality systems

- Skilled in KanBan and other customer driven quality and inventory management systems

Metal Etching Material

BE-CU is experienced in precision etching various metals, allowing customers the freedom to specify components in hundreds of different materials.

The Surface Treatment Of Metal Etching Parts

Do you want your etching parts to be more corrosion-resistant or get a specific look? Metal finishing service is a essential choice to achieve your design perfectly. BE-CU – metal-etch.com is an accomplished finished parts manufacturer, our workers and craftsman are capable to provide precision metal etching services and a wide range of finishing services including aluminum anodizing, painting, passivation, electroplating, powder coating, polishing, black oxide, conversion coating, abrasive blasting, etc. We offers several common surface finishes to help improve functionality and aesthetics.

- Anodizing (Anodized)

- Passivation

- Plating (Electroplating)

- Painting

- Black Oxide (Hot Blackening)

- Polishing

- Powder Coating

- Heat Treatment

- Satin Finish

- Abrasive blasting (Sandblasting)

- Conversion coating

- Tungsten carbide coating

After browsing a list of metal finishing services, select a process based on essential considerations, like production time, cost-effectiveness, part tolerance, durability and applications. High-tolerance metal etching parts are not recommended to apply secondary metal surface finish, because the treatment may change the sizes of the finished part through removing or adding a small amount of materials.

Other requirements or custom designs, welcome to contact us for a free quote fast!