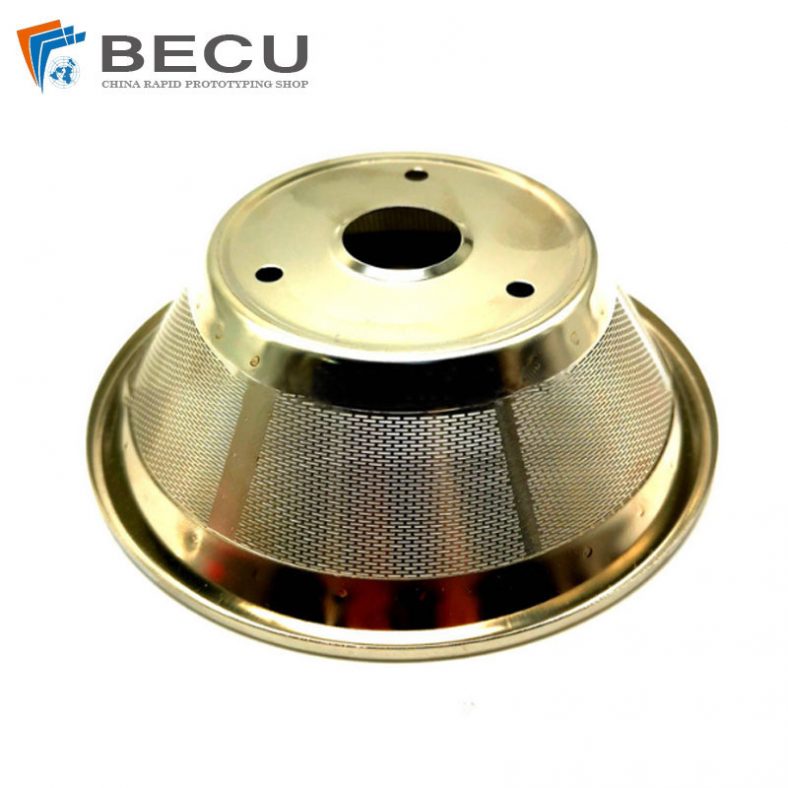

Position Code Disc

- Material: Aluminum

- Thickness: 0.5/0.6/0.7 mm

- Project Offer:Within 3 hours

- Process: Precision Etching

- Custom Cycle:Involving Mold Opening, – monthly sample delivery

- Production Capacity:5000-10000PCS/day

- Application: Disc

- Add Process:Stamping, Self-Owned Hardware Mold Room, Electroplating, Electrophoresis, PVD Vacuum Plating

- Type: Stainless Steel Etching

High-Quality Aluminum Etching Position Code Disc

The positioning plate is a mechanical part that is widely used in various machinery and is mainly used to achieve precise positioning and rotation. The positioning plate has a wide range of functions and can be used in packaging machines, labeling machines, mixers, etc. on production lines, as well as in automobile manufacturing, machine tool manufacturing, mold manufacturing, shipbuilding and other industries.

The positioning plate is mainly used to achieve precise positioning and rotation. Its functions include the following aspects:

- Achieve positioning: Use the positioning plate to match other parts with positioning holes to achieve precise positioning;

- Realize transmission: realize the transmission of other parts by driving the positioning plate;

- Maintain direction: Positioning plates are also often used in mechanical equipment to maintain direction and ensure the accuracy of machine operation;

- Matching mechanism: It forms a mechanical matching mechanism with other parts, such as servo system, stepper motor system, etc.

Characteristics Of Positioning Plate

- High accuracy: Since the positioning plate is an indispensable part of mechanical manufacturing, its accuracy and stability are very high, which can ensure the normal operation of mechanical equipment;

- Simple structure: The structure of the positioning plate is very simple, mostly in the form of a disc, and there are also some special shapes designed to facilitate manufacturing and installation;

- Wear resistance: The positioning plate is usually made of high-hardness alloy steel to improve its wear resistance and thus increase its service life;

- Large bearing capacity: When machinery and equipment need to withstand larger loads, the positioning plate can also withstand larger forces and has high strength and toughness;

- Flexible use: The positioning plate can be flexibly installed and disassembled as needed, which is very convenient for the maintenance and repair of mechanical equipment.

To sum up, the positioning plate, as a mechanical part, plays a very important role in modern industrial production. It achieves efficient operation and precise control of mechanical equipment through precise positioning and rotation. It has the characteristics of high endurance, high accuracy, and flexible use. It is an indispensable part of modern machinery manufacturing.

Why Choose Our Aluminum Etching Position Code Disc Service?

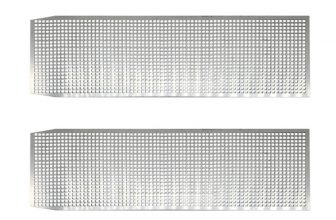

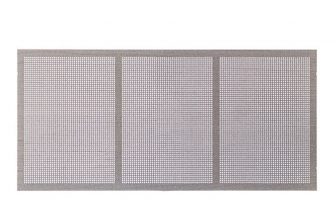

- Etching processing technology is adopted, with high precision, up to ±0.008mm (different thickness of different materials). 15 years of professional precision etching processing factory, the quality is trustworthy.

- The etching process of Be-cu has no restrictions on complex patterns and arbitrary geometric figures. No matter how complicated the hole shape or pattern is, it can be formed in one process without increasing the production cost.

- Be-cu chemical etching is a double-sided simultaneous processing technology. The surface of the product (front and back) is smooth, no bumps, no pits, no burrs, no warping, the mesh is flat and no deformation, no need to polish , Polishing, self-care process after flattening.

- The size of etching process is fine (aperture ≥ 0.1mm, thickness 0.03-2.0mm), and the positioning is accurate (minimum precision ± 0.008) uniform.

- The production cycle is short, the response is fast, and the design is easy to modify. The Be-cu professional etching technology engineering team has a total of 17 people and has senior technicians who have been in the industry for 15+ years.

- Be-cu samples are produced quickly, and samples can be produced within 1-2 working days (determined according to product requirements).

- Be-cu etching has 16 automatic etching production lines, with high etching processing output, which can meet your production orders for batch processing and etching customized microporous mesh.

- Be-cu provides auxiliary services such as stamping, welding, oil spraying, painting, electrophoresis, electroplating, electrolysis, passivation, polishing, stretching, wire drawing, silk screen LOGO, injection molding, etc., to meet the needs of different products and realize convenient and fast — One-stop processing service.

- Be-cu has passed the factory inspections of many well-known companies such as Gree, Joyoung, Xinbao, Xiaomi, Lake and American and German customers. The quality and delivery time are stable, and the customer satisfaction and employee satisfaction are high.

Contact Be Cu Now for your Custom Metal Etching, We are your best online Etching services choice!

Specifications of Aluminum Etching Position Code Disc

| Material Type | Aluminium/Brass/Copper/Nitinol/Stainless steel/Titanium |

| Size | Customized |

| Min. Hole Dia. | Dia.≥1.2xT |

| Min. Pitch | D≥1.0xT |

| Tolerance | 0.003mm |

| Material Thickness | T≥0.03mm |

| Process | Etching/Plating/Stamping/Bending/Laser cuting |

| Surface Finish | PVD/Coating/Painting |

| Inspection | IPQC/AQL |

| Packing | Plastic Tray or Customized |