Homepage » Metal Etching »

Bronze Chemical Etching – Bronze Etching

Bronze etching is a process of creating intricate designs on the surface of bronze through the use of chemical and physical methods. This technique has been utilized for centuries, serving both decorative and functional purposes. Bronze, an alloy primarily composed of copper and tin, has been favored for its durability, workability, and aesthetic appeal. Etching, a form of surface modification, allows for the creation of detailed patterns, textures, and images, transforming simple bronze objects into works of art.

The practice of bronze etching dates back to ancient civilizations, where it was used to embellish weapons, armor, and various artifacts.

Over the centuries, the techniques have evolved, reflecting the technological advancements and artistic trends of each era.

From the intricate designs of ancient Greece and Rome to the elaborate decorations of the Renaissance, bronze etching has played a significant role in the development of metalworking and decorative arts. In modern times, it continues to be a valued technique in both artistic and industrial contexts.

Looking for reliable, quick-turn bronze etching services suppliers and more precision etching product manufacturers? With advance etching line, our unparalleled design and production capacity capabilities guarantee premier OEM bronze etching Parts to worldwide customers.

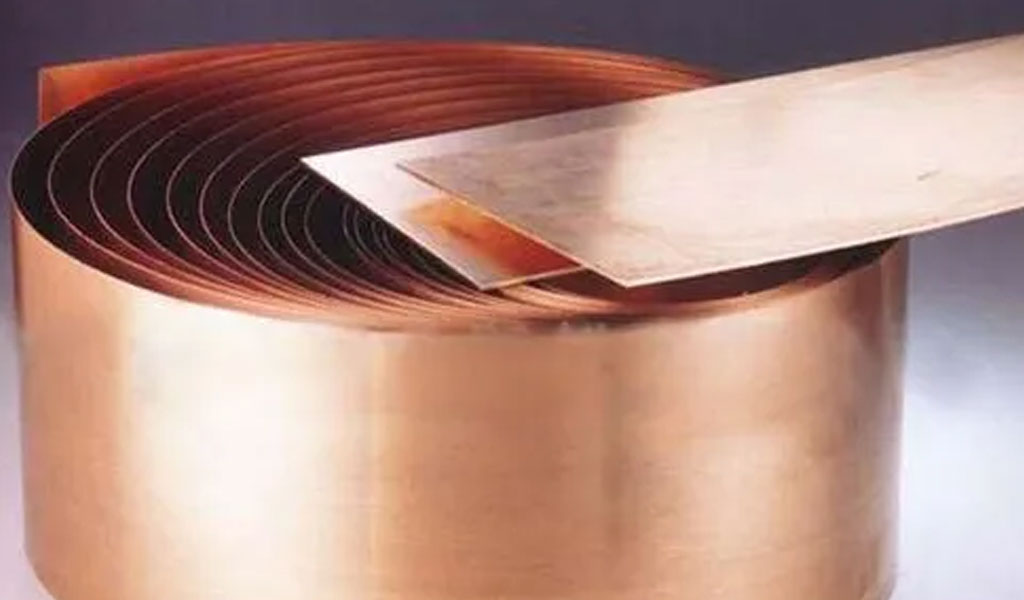

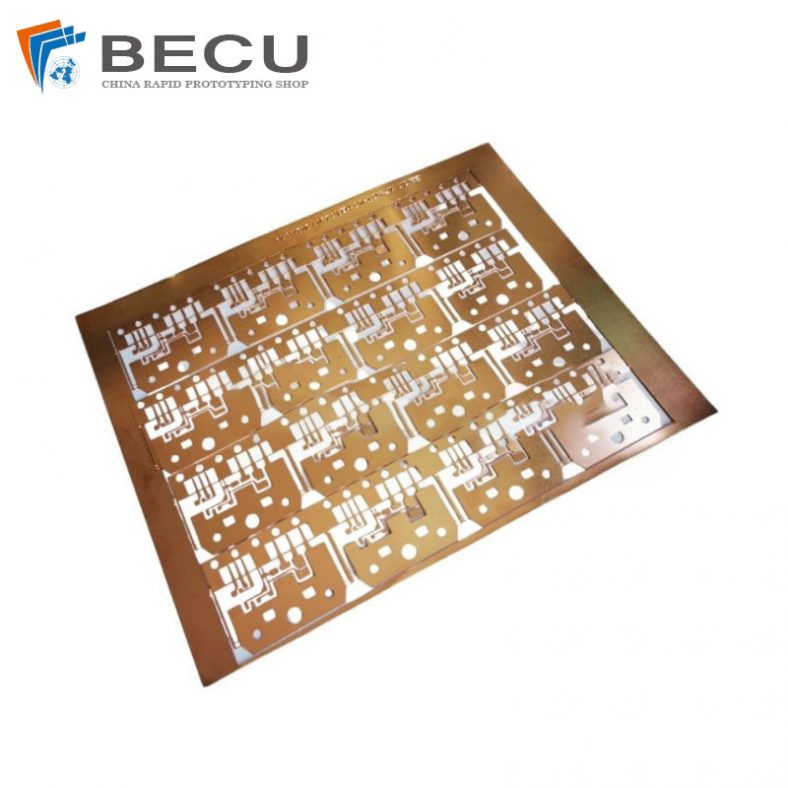

Our Bronze Plate/Sheet/Roll Etching Service

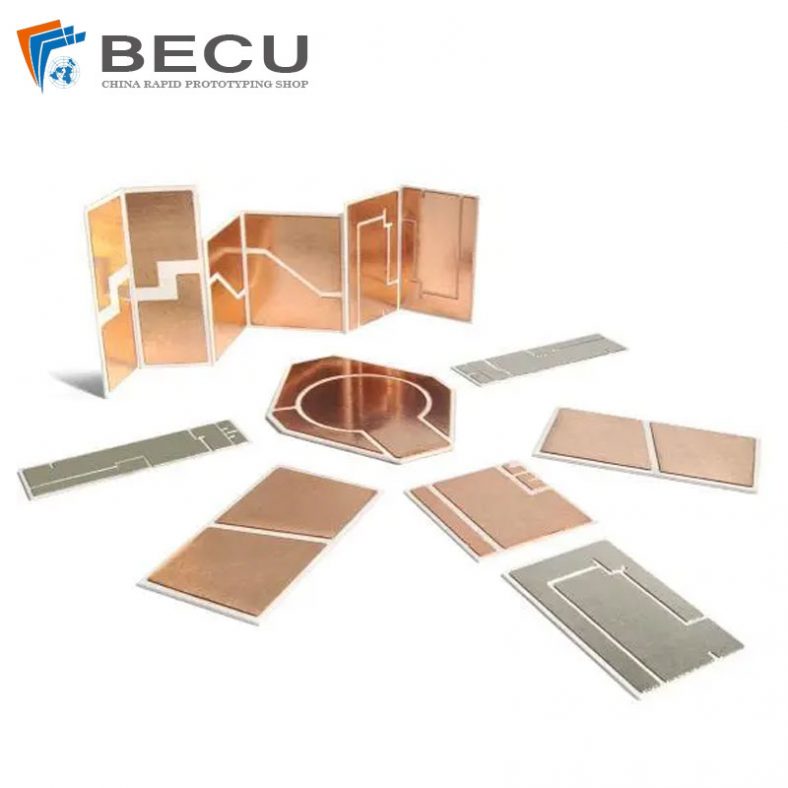

If you need bronze parts etched we are one of the most capable and affordable sources specializing in manufacturing custom etched parts on advanced photo etching machines with cnc precision. Through our Photo Chemical Etching process, the smallest and most complex designs are made possible such as electrical spring contacts, contact membranes, busbars, antennae and micro antennae, spring fingered contacts, heating elements and battery terminal as well as many other bespoke components to your own designs.

We can machine to print and accept the most common file formats including: .dwg .dxf .iges .step .sat as well as .pdf files. If you don’t see your file format here let us know. Please send us files to: [email protected] We can accept both small and large run jobs of custom bronze etching parts.

Our Etching Capabilities

- Etching of many grades of bronze

- Combining Stamping, Laser Cutting,CNC machining and photochemical etching on sheets up to 2mm thick

- Etching of up to 0.025″ thick sheets as large as 22×12 inches

- Tolerances of ±.0005″ in many applications

How To Etch Bronze

Automated-Coating

Automatic-Baking-Line

Automatic-Shearing

Coating-For-Etching-Parts

Deinking

Etching

Exposure

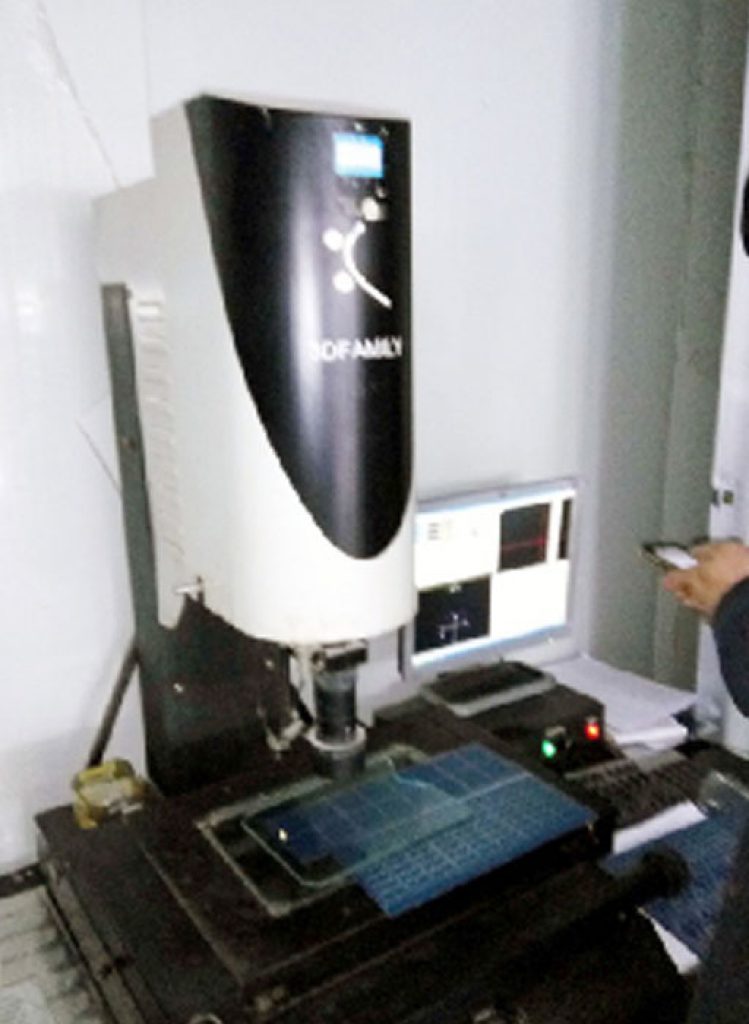

Inspection-For-Etching

Metal Grades For Bronze Etching

When it comes to bronze etching, the choice of metal grade is crucial as it affects the etching process, the quality of the final product, and its suitability for specific applications. Various bronze alloys, distinguished by their composition and properties, are used for etching. Here is an overview of the most common bronze grades and their characteristics:

Classic Bronze (C22000 – C24000)

Phosphor Bronze (C50100 – C52100)

Aluminum Bronze (C60600 – C64200)

Silicon Bronze (C65500 – C66100)

Nickel Silver Bronze (C74500 – C79900)

More Bronze Grades

By selecting the appropriate bronze grade and following best practices for etching, artists and craftsmen can create intricate and durable designs that showcase the beauty and versatility of this ancient metal.

Components That Are Produced By Etching Bronze

The popularity of bronze makes it a desirable metal for use in fabrication because it is easy to manufacture and has favorable properties for many industrial products.With the photo etching process, the metal is etched evenly without any structural deformations from the hard tooling used in stamping and punching.Since there isn’t a heat point of contact like laser cutting, the parts’ metal properties remain unchanged and free from thermal deformations.Get inspired by our custom etching part projects and contact us to Get Instant Quote for rapid prototype or bronze etching parts start from 1pcs.

-

Copperplate Engravings Of World Famous Works

-

Artistic Etched Copper Shielding Electronics Playing Cards with Patterns

-

IC Lead Frame and VFD Dedicated Grid Etching

-

Ceramic Copper Clad Laminate By Precision Etching

-

Precision Etching 0.15mm Copper Laptop Vapor Chamber

-

Etched Beryllium Copper 17200 Lead Frames

-

Precision Etched Copper Alloy Leadframe

-

Beryllium Copper Etched Vibration Spring Leaf

Metal Etching Certification,Equipment List and Quality

We are committed to enlisting the full support of all employees to continuously improve our processes and enhance quality, thereby fulfilling our customer's needs with defect free products and services, on time and every time

- ISO 9001:2015 certified

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process FMEA

- Fully compliant with the exacting requirements of our customers

- ITAR registered

- NIST cybersecurity standard compliant

- Proprietary Patented quality systems

- Skilled in KanBan and other customer driven quality and inventory management systems

Metal Etching Material

BE-CU is experienced in precision etching various metals, allowing customers the freedom to specify components in hundreds of different materials.

The Surface Treatment Of Metal Etching Parts

Do you want your etching parts to be more corrosion-resistant or get a specific look? Metal finishing service is a essential choice to achieve your design perfectly. BE-CU – metal-etch.com is an accomplished finished parts manufacturer, our workers and craftsman are capable to provide precision metal etching services and a wide range of finishing services including aluminum anodizing, painting, passivation, electroplating, powder coating, polishing, black oxide, conversion coating, abrasive blasting, etc. We offers several common surface finishes to help improve functionality and aesthetics.

- Anodizing (Anodized)

- Passivation

- Plating (Electroplating)

- Painting

- Black Oxide (Hot Blackening)

- Polishing

- Powder Coating

- Heat Treatment

- Satin Finish

- Abrasive blasting (Sandblasting)

- Conversion coating

- Tungsten carbide coating

After browsing a list of metal finishing services, select a process based on essential considerations, like production time, cost-effectiveness, part tolerance, durability and applications. High-tolerance metal etching parts are not recommended to apply secondary metal surface finish, because the treatment may change the sizes of the finished part through removing or adding a small amount of materials.

Other requirements or custom designs, welcome to contact us for a free quote fast!