Homepage » Metal Etching »

Kovar Etching

Kovar was developed in the early 20th century by the Westinghouse Electric & Manufacturing Company, primarily for its use in electronic sealing applications. The name “Kovar” is derived from “Ko” for cobalt and “var” for various other elements that contribute to its unique properties. The alloy’s development was driven by the need for materials that could match the thermal expansion characteristics of glass, making it indispensable in the manufacture of hermetic seals for electronic components.

Kovar etching refers to the process of chemically or physically removing material from Kovar, a nickel-cobalt ferrous alloy, to achieve desired shapes, patterns, or surface finishes. Kovar is particularly noted for its low coefficient of thermal expansion, making it suitable for use in applications where a precise fit between metal and glass or ceramics is necessary, such as in the electronics and aerospace industries.

Top-Grade Kovar Etching Service – Cost-Effective Kovar Etching Parts

Looking for reliable, quick-turn Kovar Etching services suppliers and metal etching product manufacturers? With advanced chemical etching production line, our unparalleled design and production capacity capabilities guarantee premier OEM Kovar Etching Parts to worldwide customers. At BE-CU – China Top Metal Etching Supplier, you can find comprehensive certified chemical etching process in kovar materials for rapid prototyping and low-volume production of end-use components or full item.

Our Etching Capabilities

- Etching of many grades of kovar, including 4J29,ASTM F-15, NILO K, Pernifer 2918,Dilver P-153

- Combining Stamping, Laser Cutting,CNC machining and photochemical etching on sheets up to 2mm thick

- Etching of up to 0.025″ thick sheets as large as 22×12 inches

- Tolerances of ±.0005″ in many applications

Properties of Etching Grade Kovar

Etching Grade Kovar maintains the standard composition of Kovar with approximately 29% nickel, 17% cobalt, and the balance iron, along with trace amounts of elements such as manganese and silicon. However, this specific grade may undergo additional refinement processes to enhance its suitability for etching applications.

Thermal Expansion

The key property of Etching Grade Kovar is its precise control over the coefficient of thermal expansion (CTE). This controlled expansion is crucial for ensuring that the metal does not expand or contract differently from the materials it is bonded with, preventing stress and potential failure at the interfaces.

Mechanical Properties

Etching Grade Kovar offers excellent mechanical properties, including good ductility and tensile strength, which can be fine-tuned through heat treatment processes. These properties are essential for maintaining structural integrity during the etching process and in the final application.

Surface Finish and Purity

One of the critical attributes of Etching Grade Kovar is its surface finish and purity. The material is often supplied with a high-quality surface finish, free from impurities and defects that could interfere with the etching process. This ensures that the etching results are consistent and precise.

How To Etch Kovar

Automated-Coating

Automatic-Baking-Line

Automatic-Shearing

Coating-For-Etching-Parts

Deinking

Etching

Exposure

Inspection-For-Etching

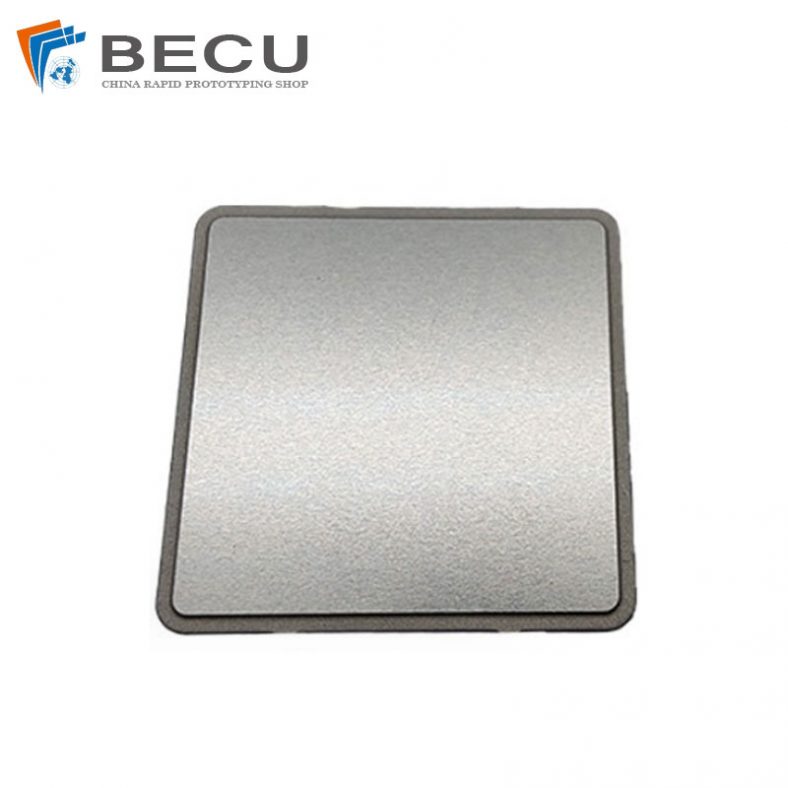

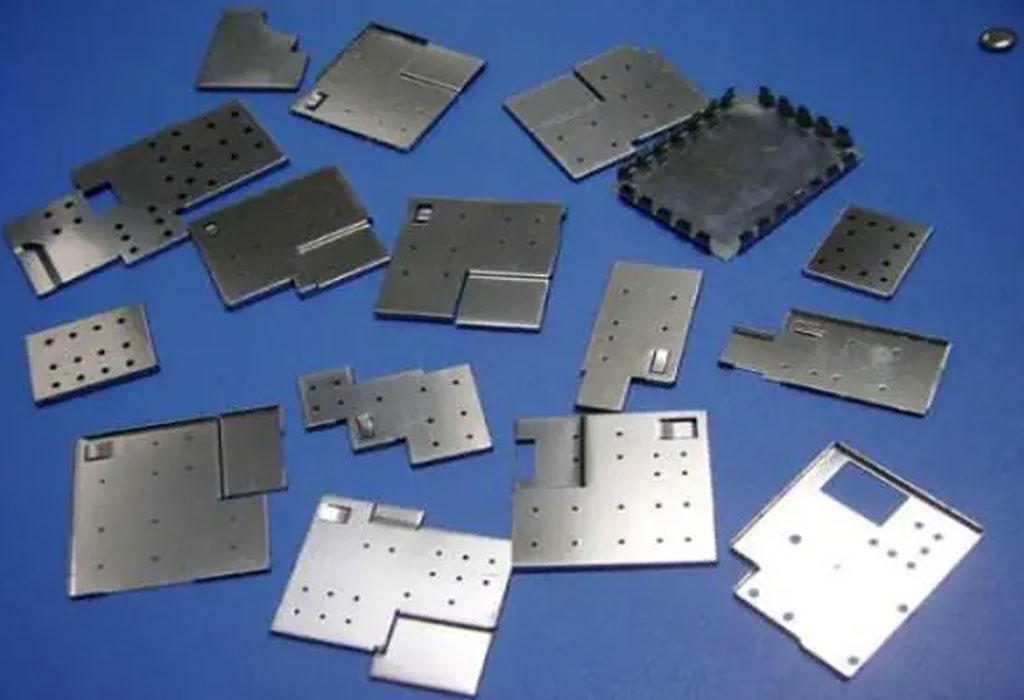

Components That Are Produced By Etching Kovar

The popularity of kovar makes it a desirable metal for use in fabrication because it is easy to manufacture and has favorable properties for many industrial products.With the photo etching process, the metal is etched evenly without any structural deformations from the hard tooling used in stamping and punching.Since there isn’t a heat point of contact like laser cutting, the parts’ metal properties remain unchanged and free from thermal deformations.Get inspired by our custom etching part projects and contact us to Get Instant Quote for rapid prototype or kovar etching parts start from 1pcs.

Metal Etching Certification,Equipment List and Quality

We are committed to enlisting the full support of all employees to continuously improve our processes and enhance quality, thereby fulfilling our customer's needs with defect free products and services, on time and every time

- ISO 9001:2015 certified

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process FMEA

- Fully compliant with the exacting requirements of our customers

- ITAR registered

- NIST cybersecurity standard compliant

- Proprietary Patented quality systems

- Skilled in KanBan and other customer driven quality and inventory management systems

Metal Etching Material

BE-CU is experienced in precision etching various metals, allowing customers the freedom to specify components in hundreds of different materials.

The Surface Treatment Of Metal Etching Parts

Do you want your etching parts to be more corrosion-resistant or get a specific look? Metal finishing service is a essential choice to achieve your design perfectly. BE-CU – metal-etch.com is an accomplished finished parts manufacturer, our workers and craftsman are capable to provide precision metal etching services and a wide range of finishing services including aluminum anodizing, painting, passivation, electroplating, powder coating, polishing, black oxide, conversion coating, abrasive blasting, etc. We offers several common surface finishes to help improve functionality and aesthetics.

- Anodizing (Anodized)

- Passivation

- Plating (Electroplating)

- Painting

- Black Oxide (Hot Blackening)

- Polishing

- Powder Coating

- Heat Treatment

- Satin Finish

- Abrasive blasting (Sandblasting)

- Conversion coating

- Tungsten carbide coating

After browsing a list of metal finishing services, select a process based on essential considerations, like production time, cost-effectiveness, part tolerance, durability and applications. High-tolerance metal etching parts are not recommended to apply secondary metal surface finish, because the treatment may change the sizes of the finished part through removing or adding a small amount of materials.

Other requirements or custom designs, welcome to contact us for a free quote fast!